Trigger type sprayer

A sprayer and trigger technology, applied in the direction of spraying devices, liquid spraying devices, single handheld devices, etc., can solve problems such as injuries and children's unsafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

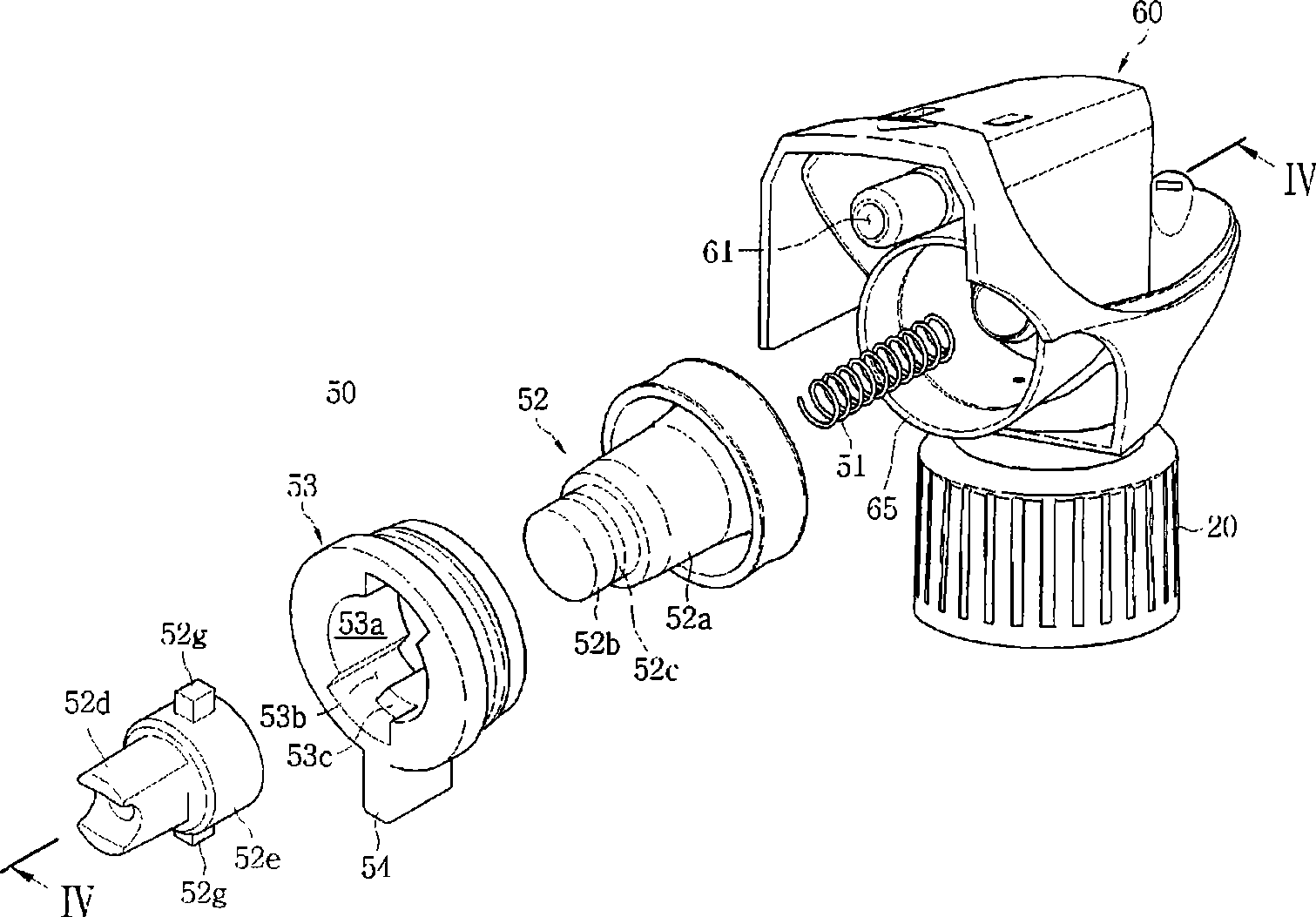

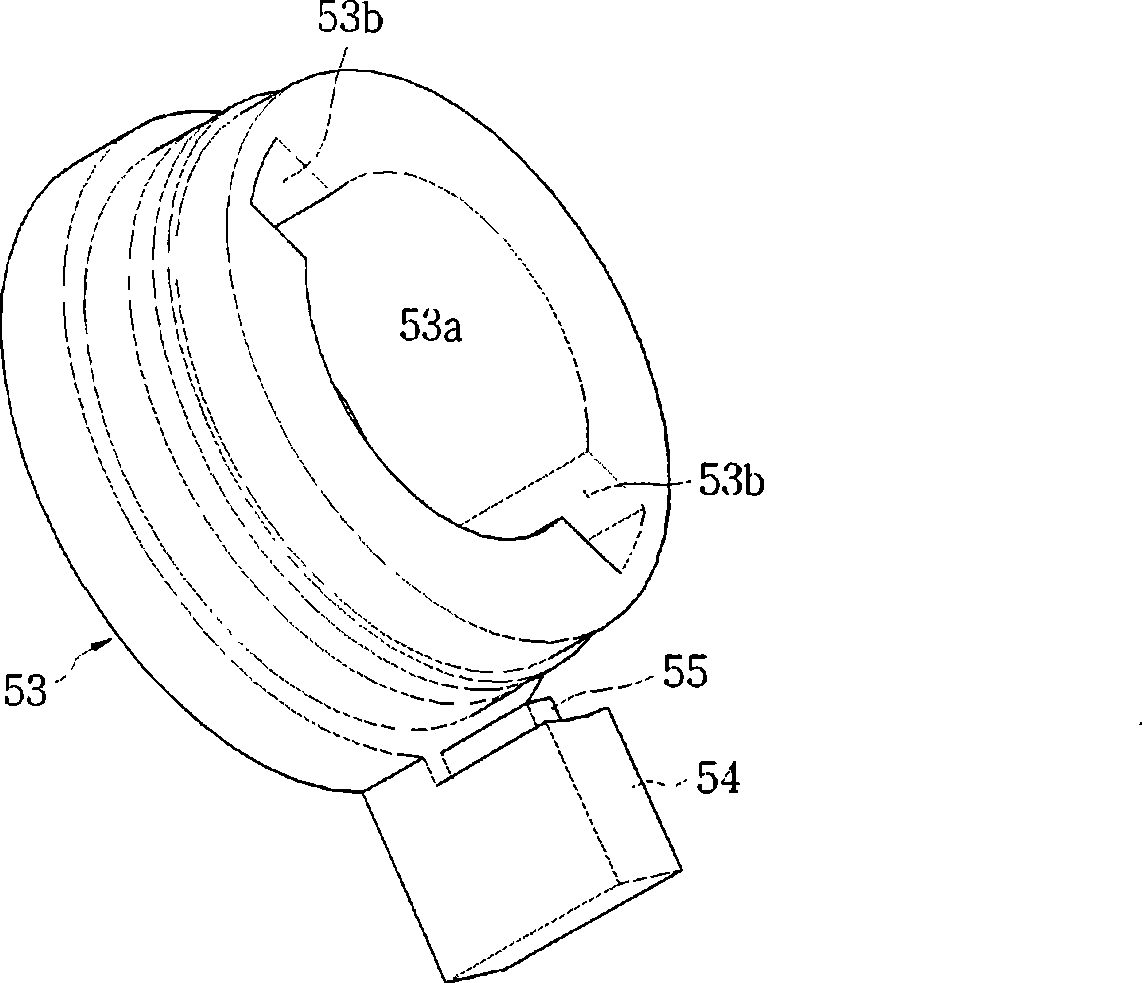

[0043] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

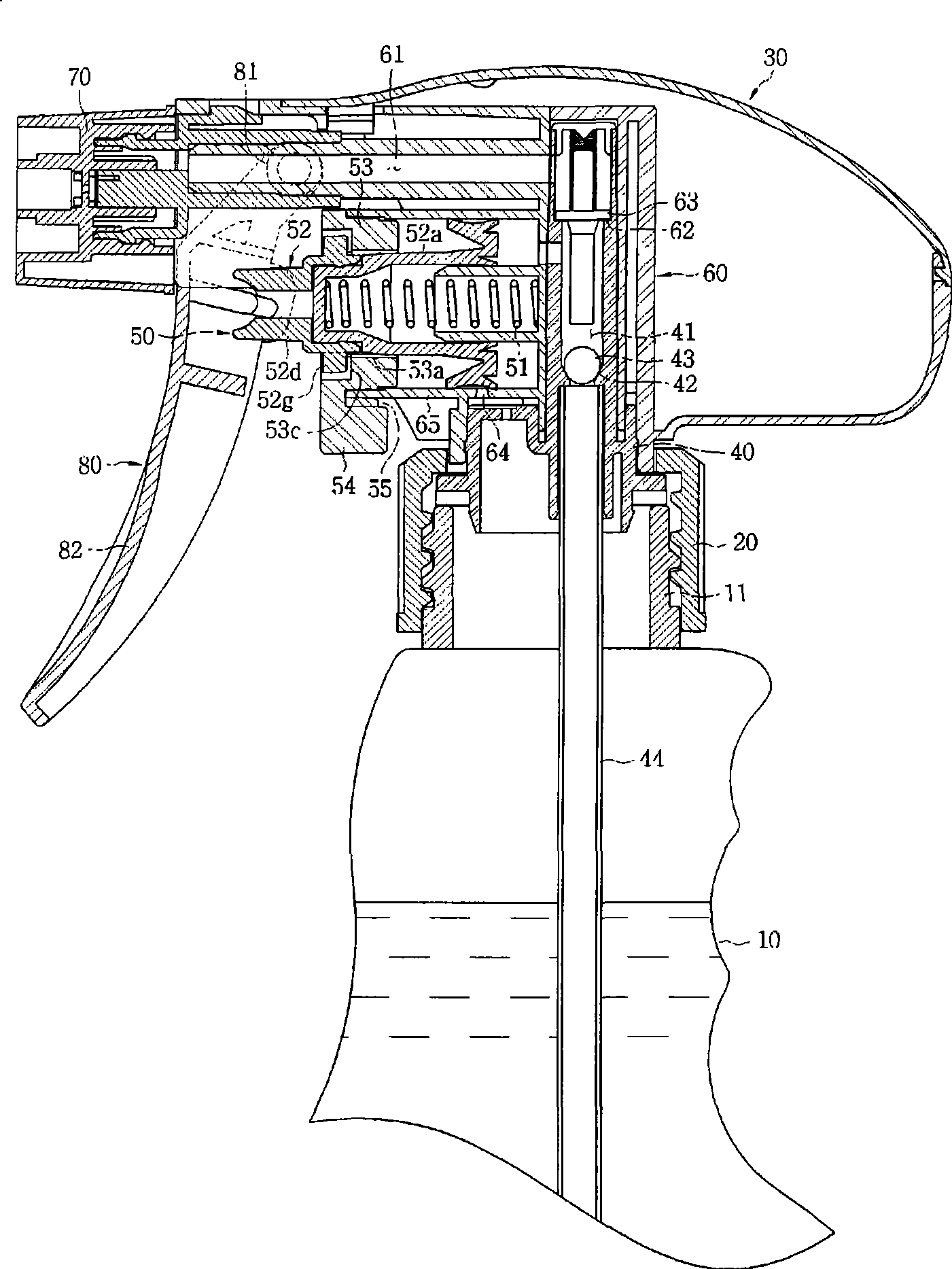

[0044] figure 1 is a sectional view showing a trigger injector device according to the present invention.

[0045] Such as figure 1 As shown, the small injector adopting the concept of the present invention comprises: a container 10 for storing a liquid substance; a cover 20 detachably coupled to the upper part of the container 10; an injector device 30 mounted on the cover 20 for pumping Suction and ejection of liquid substances.

[0046] The container 10 is made of synthetic resin to accommodate liquid substances. The container 10 includes a neck 11 having a certain inner diameter and integrally formed at an upper portion of the container 10 . The neck 11 is externally threaded on the outer surface to be combined with the cap 20 .

[0047] The cap 20 detachably couples the injector device 30 to the neck 11 of the container 10 . The cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com