Preparation method for macroporous hydroxyapatite ceramic

A technology of macroporous hydroxyapatite and hydroxyapatite, which is applied in the field of ceramic materials, can solve the problems of easy introduction of impurities and inflexible control of pore structure, and achieves the effects of simplified process, low cost and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Using a homogeneous aqueous solution of polyvinyl alcohol 2099 (the degree of polymerization is 2000, and the degree of alcoholysis is 99%) with a concentration of 6.75wt% is used as a binder, and concentrated hydrochloric acid (37%, mass fraction) is used to adjust the polyvinyl alcohol After the pH value reaches 6, add hydroxyapatite, powder with a particle size of 100 nanometers and polyvinyl alcohol aqueous solution at a mass ratio of 4:22 into a polypropylene tank, without adding surfactant lauryl sulfate Sodium: Add corundum balls according to the ball-to-material ratio of 1.5:1, seal, slowly mix until uniform, and then oscillate for 0.5 hours, and transfer the uniformly oscillated slurry to -17 o C, put in the freezer and continue to freeze for 9 hours. Transfer the frozen sample directly to anhydrous or industrial ethanol to extract the water in the sample. The extraction time is 5 hours. This extraction process is repeated again, and then the sample ...

Embodiment 2

[0039] Embodiment 2: The preparation process is the same as that of Example 1, except that hydroxyapatite, whose particle size is 100 nanometers, is mixed with polyvinyl alcohol aqueous solution at a mass ratio of 4.5:22;

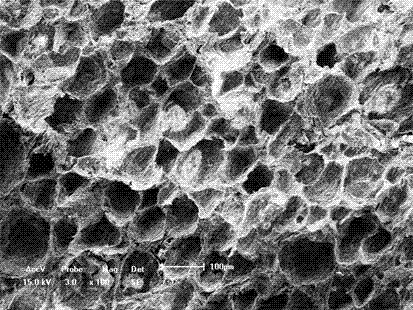

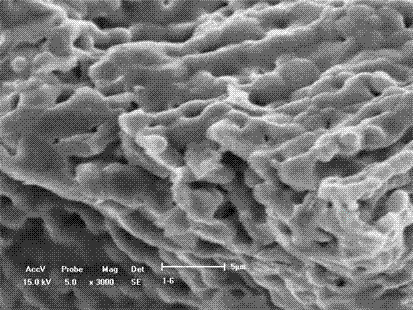

[0040] Depend on image 3 It can be seen that the macropore diameter of the macroporous hydroxyapatite ceramics prepared in this embodiment is 120 μm. When the content of polyvinyl alcohol is constant, the increase of the amount of hydroxyapatite will cause the increase of the pore diameter, and the connectivity is better; Figure 4 The laser confocal optical photographs clearly show that the diameter of the communication holes between the macropores is 30-70 μm.

Embodiment 3

[0041] Example 3: The difference between the preparation process and Example 1 is that after shaking for 0.5 hours, mechanical stirring was carried out for 10 minutes, and the rotation speed was 1200 rpm.

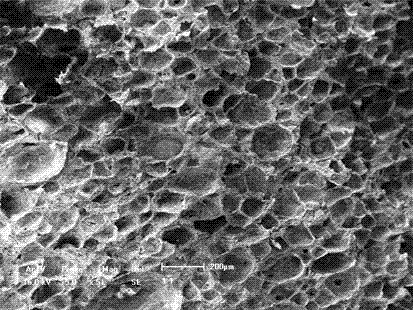

[0042] Depend on Figure 5 It can be seen that the macropore diameter of macroporous hydroxyapatite ceramics prepared in this example is 150-200 μm. When the content of hydroxyapatite is constant, the increase of polyvinyl alcohol will gradually increase the pore size, and the pore wall will gradually become thinner, and the connectivity will be improved. better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com