Low-carbon CrNiMo gear steel and preparation method thereof

A gear steel and molten steel technology, applied in the field of gear steel, can solve the problems of reducing the service life of steel, fatigue cracks, etc., and achieve the effect of improving the purity of molten steel and improving the quality of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

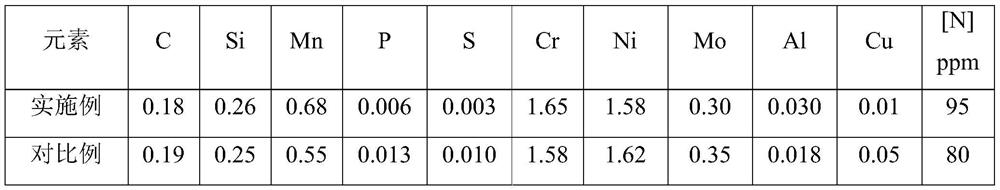

[0055] A low-carbon CrNiMo gear steel, including the following chemical composition in mass percentage: C: 0.18%, Si: 0.26%, Mn: 0.68%, P: 0.006%, S: 0.003%, Cr: 1.65%, Ni: 1.58%, Mo: 0.30%, Al: 0.030%, [N]: 0.0095%, Cu: 0.01%, and others are Fe and unavoidable impurities.

[0056] The preparation method of the above-mentioned low-carbon CrNiMo gear steel includes the following steps: molten iron→electric furnace smelting→LF refining→VD vacuum treatment→continuous casting→slow cooling→finishing→weighing→marking→warehousing.

[0057] Electric furnace smelting:

[0058] Using hot metal hot charging technology, the ratio of molten iron is 82.3%.

[0059] 1. Tapping indicators: tapping [C] 0.08%; tapping [P] 0.0035%; tapping temperature 1688°C.

[0060] 2. Requirements for tapping auxiliary materials: add aluminum 1.3kg / t, lime 8kg / t, and cleaning agent 3kg / t.

[0061] 3. LF arrival index: C: 0.14%, Si: 0.18%, Mn: 0.60%, Cr: 1.62%; temperature 1580°C. Add metal elements or all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com