Method for producing wheel steel by adopting LF-RH refining process

A technology of wheel steel and process, which is applied in the field of wheel steel produced by LF+RH refining process, can solve the problems that inclusions are easy to exceed the standard, and achieve the effect of being conducive to fully floating and ensuring sedation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The specific implementation process is single pouring and 2 furnaces are produced at a time, and a certain type of wheel steel is produced by using the "two-step method" converter smelting-LF-RH refining-continuous casting' process route, and its final composition is shown in Table 1.

[0037] Soft blowing starts at the end of LF refining. The control parameters of LF and RH processes are shown in Table 1, and the rating results of inclusions in steel coils are shown in Table 2.

[0038] Table 1 Some parameters of LF-RH treatment process

[0039]

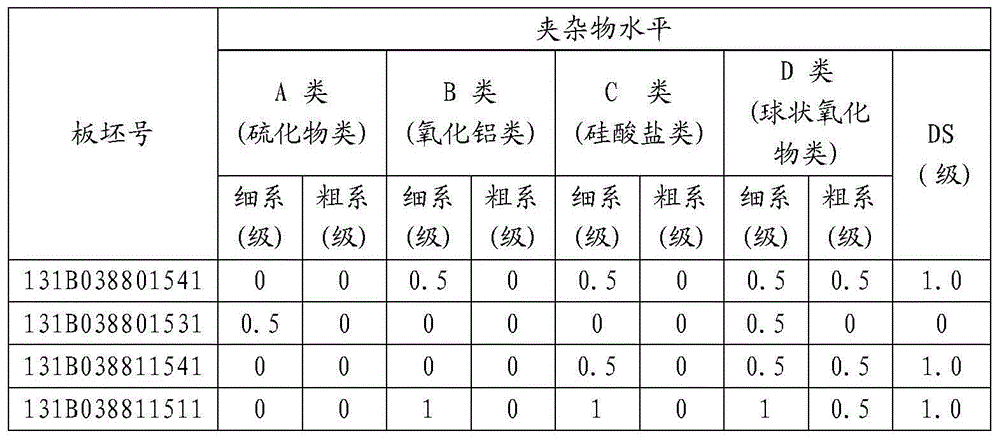

[0040] Table 2 Classification results of inclusions in steel coils

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com