Reinforcing phase metallic gradient composite material manufacturing process and equipment thereof

A composite material and manufacturing process technology, applied in the field of reinforced phase metal gradient composite material manufacturing process and equipment, can solve the problems of inability to manufacture alloy layer composite products, slow cooling speed of matrix materials, coarse crystal structure, etc. Secondary heating process, avoid internal inclusions and pores, and improve the effect of casting infiltration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

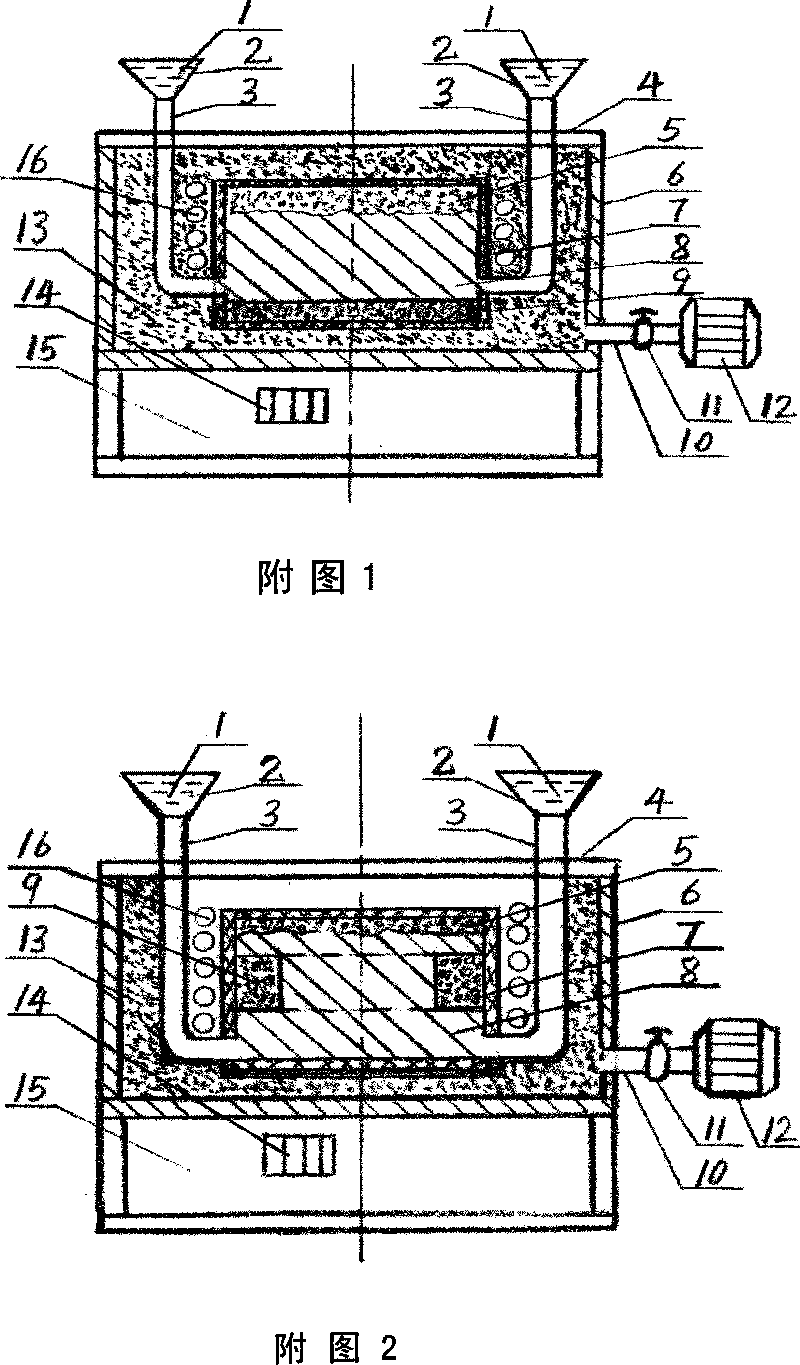

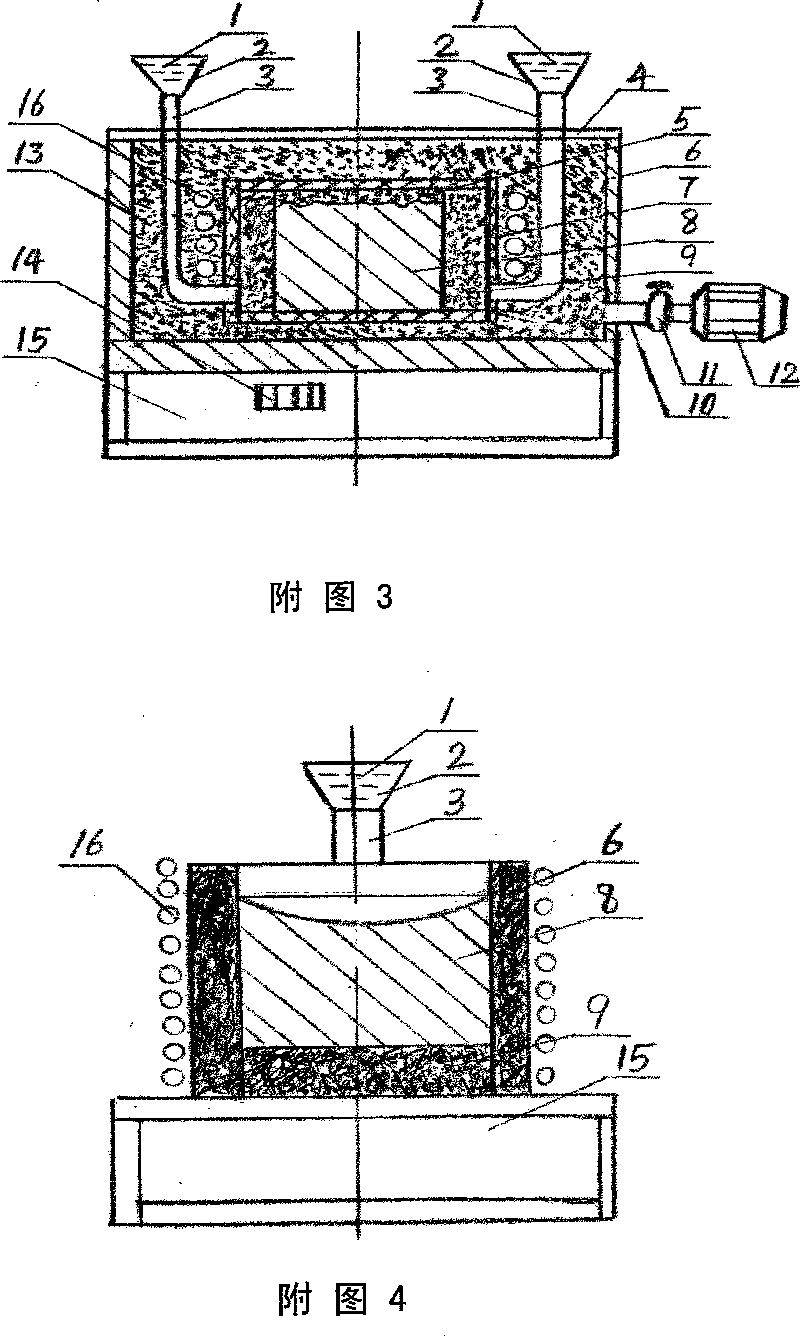

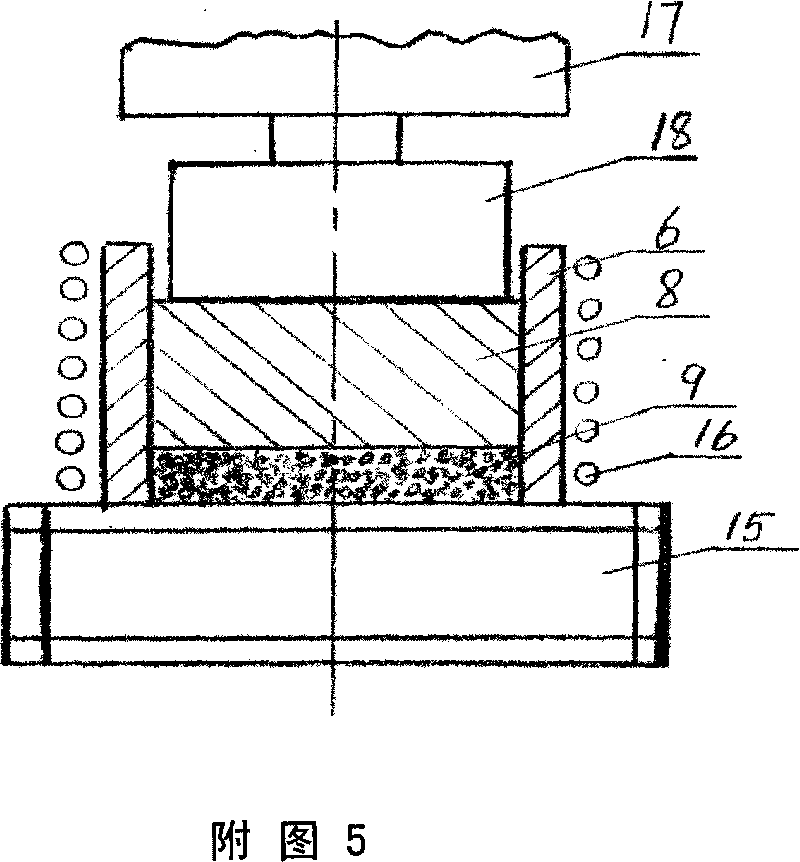

[0018] Embodiment 1: In Fig. 1, this equipment has a workbench 15, on the top of the workbench 15, a sand box 6 is installed, on the top of the sand box 6, a sand box cover 4 is installed, on any side of the sand box 6 There is a vacuum pipeline 10, the vacuum pipeline 10 is connected with the control valve 11 and the vacuum pump 12, an electromagnetic induction heater 16 is installed outside the model 5 in the sand box 6, and an electric vibrator 14 is installed on the workbench 15. 6 or the top or side of the sand mold 6 is equipped with pouring funnel 2, and pouring runner 3 is connected with pouring funnel 2 below.

[0019]At the beginning of the work, firstly, materials with special properties such as reinforced particles or reinforced short fibers or solid self-lubricating materials or boron-containing self-fluxing alloys are mixed with binders and solvents, or various strong carbides and nitrides are formed into elemental alloys Powder and carbon powder, nitrogen-contai...

Embodiment 2

[0020] Example 2: In figure 2 Among them, the difference with Fig. 1 is that the alloy paste block 9 is fixed in the middle part of the polystyrene foam plastic model 5, and repeating the composite process of Example 1 can be manufactured into a large thickness containing the alloy layer material in the middle part of the composite material The graded functional composite material 8 or casting product 8 of the alloy layer. Other processes and equipment are the same as in Embodiment 1, omitted.

Embodiment 3

[0021] Embodiment 3: in Fig. 3, the difference with Fig. 1 is that the alloy paste block 9 is fixed on the entire outer surface of the polystyrene foam model 5, and the compound process of repeating embodiment 1 can be manufactured in the composite material The functionally graded composite material 8 or cast product 8 of a large thickness alloy layer containing the alloy layer material on the entire outer surface. Other processes and equipment are the same as in Embodiment 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com