Device and method for adjusting argon flow of bottom blowing for steel ladle during LF refining and standing period

A technology of bottom blowing argon and argon flow, which is applied in the flow control of electric devices, etc., can solve the problems of meaningless flow adjustment, high dependence on process parameter stability, and inability to obtain argon flow accurately, etc., to achieve large Promote the use value, improve the cleanliness of molten steel, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

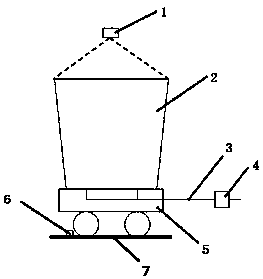

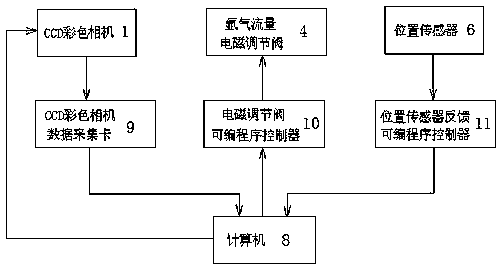

[0043] The principle of the present invention is: due to the temperature difference between the molten steel and the steel slag, the brightness of the two is also quite different. Because the molten steel temperature is high, the brightness value is relatively large; the steel slag temperature is low, the brightness value is relatively small. When the bottom blowing argon gas flow rate is small, the lamination of molten steel and steel slag is more obvious, and the temperature change range of the two is also small. With the increase of bottom-blown argon gas flow rate, the molten steel starts to contact with steel slag under the stirring of argon gas, so as to continuously transfer its own heat to steel slag, so that the temperature of steel slag begins to increase, and the brightness also begins to increase. In addition, under the continuous erosion of molten steel, the thickness of the slag layer near the blowing bricks at the bottom of the ladle begins to decrease, which wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com