Flow control device and method for improving cleanliness of molten steel in pouring process

A cleanliness and molten steel technology, applied in the field of flow control devices and molten steel pouring equipment, can solve the problems of low molten steel yield, large fluctuations in molten steel quality, secondary oxidation of molten steel, etc., to improve the cleanliness of molten steel and increase the yield of molten steel The effect of reducing the clogging of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

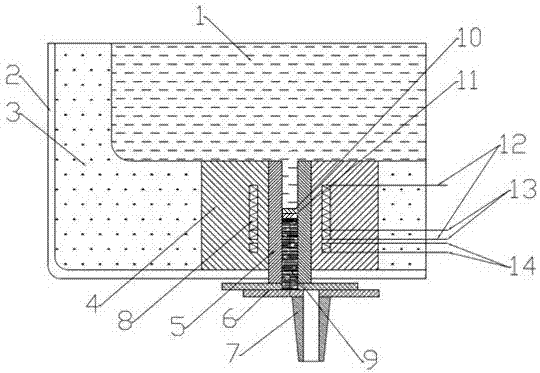

[0040] The structure of the flow control device is as figure 1 As shown, it includes a seat brick 4, an upper nozzle 5, a lower nozzle 7, a slide plate 6, a coil 8 and drainage sand 9. Wherein the coil 8 is fixed in the seat brick 4 at a position corresponding to the bottom of the ladle, and its optimal parameters are 200mm away from the molten steel, the length of the coil is 150mm, and the diameter is 280mm.

[0041] The block 4 with the coil 8 is built into the bottom of the ladle, and before the ladle is filled with molten steel, the chrome drainage sand 9 is added to the upper nozzle 5 by mechanical feeding method to ensure that the sand filling is in place and the nozzle is fully filled. The molten steel is poured into the ladle from the converter, and then the ladle goes through the LF refining process, and the refining time is between 70 and 100 minutes. After refining, when the ladle sits on the ladle turret, turn on the power supply of the induction heating coil 12,...

Embodiment 2

[0044] The structure of the flow control device is as in Example 1, and the operation method is as in Example 1. The difference is that after the molten steel is injected into the ladle from the converter, the ladle goes through the LF+RH refining process, and the refining time is 100-150 minutes.

[0045] After adopting the method of the present invention to control the flow, a total of 59 ladles were poured, and the automatic pouring rate of the ladle was 100%. At the same time, the remaining steel in the ladle was reduced, and the yield of molten steel was increased to a certain extent. The condition of the tundish is better, the clogging of the nozzle has been improved to a certain extent, and the number of continuous pouring furnaces of the tundish has been increased. At the same time, the labor intensity of the large package operators is reduced, and the working environment of the operators is improved. This method has created good conditions for the production to run sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com