Austenitic stainless steel smelted through laterite-nickle ore and production process of austenitic stainless steel

A technology for austenitic stainless steel and laterite nickel ore, which is applied in the field of stainless steel smelting technology, can solve the problems of long time for product formation, large equipment investment, and many production processes, so as to improve internal quality, reduce intermediate processes, and increase molten steel loading capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a kind of smelting austenitic stainless steel by using laterite nickel ore, and its chemical composition weight percentage ratio is: C: 0.042%, Si: 0.49%, Mn: 1.02%, Cr: 18.07%, Ni: 8.03% , N: 0.044%, Cu: 0.02%, P: 0.0287%, S: 0.0026%, O: 0.0042%, Ti: 0.008%, Mo: 0.025%, the rest are Fe and unavoidable impurity elements; Dg value = 6.98 .

[0034] The production process of the above-mentioned austenitic stainless steel is as follows:

[0035] Now take the production of austenitic stainless steel in φ5×40m drying kiln, φ4.4×100m rotary kiln, 33000KVA submerged arc furnace, 75tAOD furnace, LF ladle refining furnace, and a first-class 200*1600mm slab continuous casting machine as an example. Describe the production technique of the present invention:

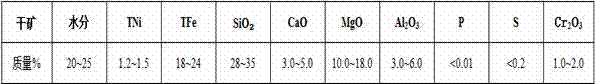

[0036] (1) Match laterite nickel ore with different grades so that Ni in laterite nickel ore is 1.3~1.6%, Fe is 20.0~26.0%, P<0.01%;

[0037] (2) Use dry kiln coal powder as fuel to reduce the wat...

Embodiment 2

[0066] This embodiment provides a kind of smelting austenitic stainless steel by using laterite nickel ore, and its chemical composition weight percentage ratio is: C: 0.040%, Si: 0.54%, Mn: 1.05%, Cr: 18.12%, Ni: 8.04% , N: 0.046%, Cu: 0.04%, P: 0.0264%, S: 0.0039%, O: 0.0037%, Ti: 0.007%, Mo: 0.024%, the rest are Fe and unavoidable impurity elements; Dg value = 7.38 .

[0067] The production process of the austenitic stainless steel in the present embodiment is as follows:

[0068] Now take the production of austenitic stainless steel in φ5×40m drying kiln, φ4.4×100m rotary kiln, 33000KVA submerged arc furnace, 75tAOD furnace, LF ladle refining furnace, and a first-class 200*1600mm slab continuous casting machine as an example. Describe the production technique of the present invention:

[0069] (1) With different grades of lateritic nickel ore, Ni is 1.3~1.6%, Fe is 20.0~26.0%, P<0.01%;

[0070] (2) Dry kiln coal powder as fuel to reduce the water content of laterite ore...

Embodiment 3

[0100]This embodiment provides a kind of smelting austenitic stainless steel by using laterite nickel ore, and its chemical composition weight percentage ratio is: C: 0.039%, Si: 0.43%, Mn: 1.06%, Cr: 18.16%, Ni: 8.07% , N: 0.047%, Cu: 0.04%, P: 0.0291%, S: 0.0051%, O: 0.0045%, Ti: 0.006%, Mo: 0.023%, the rest are Fe and unavoidable impurity elements; Dg value = 6.85 .

[0101] The production process of the austenitic stainless steel in the present embodiment is as follows:

[0102] Now take the production of austenitic stainless steel in φ5×40m drying kiln, φ4.4×100m rotary kiln, 33000KVA submerged arc furnace, 75tAOD furnace, LF ladle refining furnace, and a first-class 200*1600mm slab continuous casting machine as an example. Describe the production technique of the present invention:

[0103] (1) With different grades of lateritic nickel ore, Ni is 1.3~1.6%, Fe is 20.0~26.0%, P<0.01%;

[0104] (2) Dry kiln coal powder as fuel to reduce the water content of laterite ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com