Smelting process for reducing desulfurization rate of molten sulfur bearing steel

A technology for desulfurization rate and sulfur-containing steel, applied in the field of metallurgical industry, can solve the problems of unfavorable sulfur-containing steel in stable control, reduction of steel quality level, secondary pollution, etc., to ensure the purity of molten steel, less slag, convenient The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

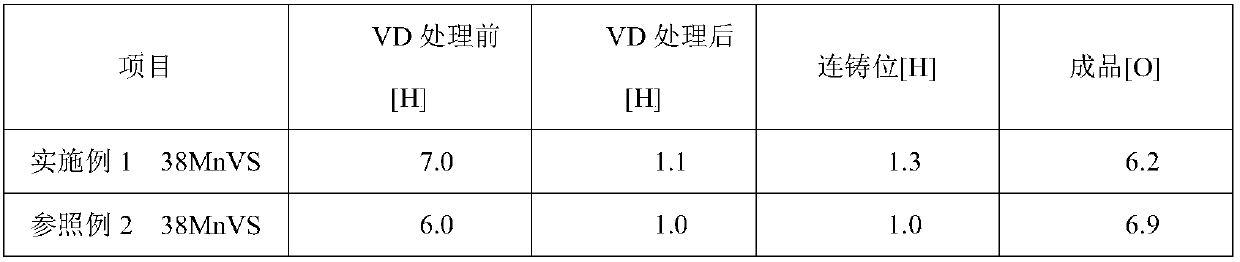

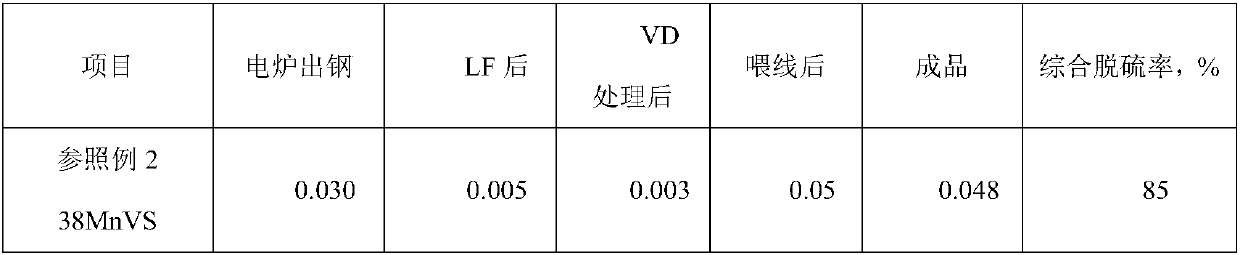

Embodiment 1

[0024] Adopt the inventive method to smelt hot-rolled round steel 38MnVS (standard requirement [S] 0.045~0.065%, [O]≤20ppm), comprise the following steps:

[0025] 1) The tapping temperature of the electric furnace is 1685°C. During the tapping process, 5.5kg / t of pre-melted slag and deoxidizer are added to the ladle.

[0026] 1.0kg / t steel, 101 tons of steel;

[0027] 2) Hoist the primary steel ladle to the VD position, press the argon blowing pipe, and feed the sulfur wire according to the requirement of 0.065% in consideration of the sulfur recovery rate, take samples to analyze the composition and determine the hydrogen, cover the vacuum cover to evacuate, and in high vacuum Degree (133Pa) under the time of 16 minutes;

[0028] 3) Lift the ladle to the LF furnace position, connect the argon gas pipe for power transmission, add lime 2kg / t steel, fluorite 50kg, add SiC powder 100kg in batches to the slag surface after the slag is melted, and feed Al wire 1.5m / t steel, Keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com