Austenitic stainless steel for electronic products and preparation method of austenitic stainless steel

A technology for austenitic stainless steel and electronic products, which is applied in the field of austenitic stainless steel for electronic products and its preparation, and can solve the problems of poor magnetic permeability index of austenitic stainless steel, high chromium-nickel equivalent of stainless steel, poor corrosion resistance, etc. , to achieve the effect of improving the purity of molten steel, uniform composition of molten steel, and eliminating secondary defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

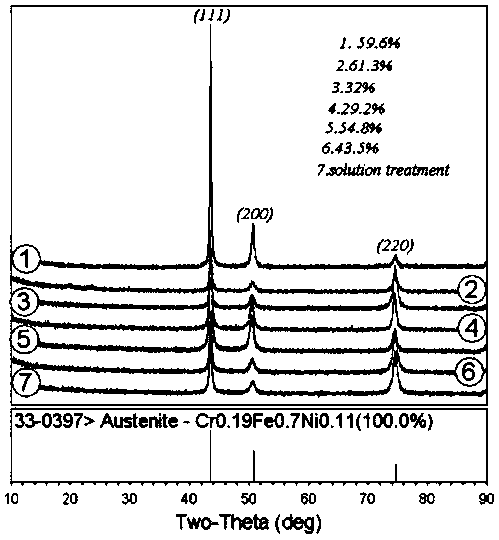

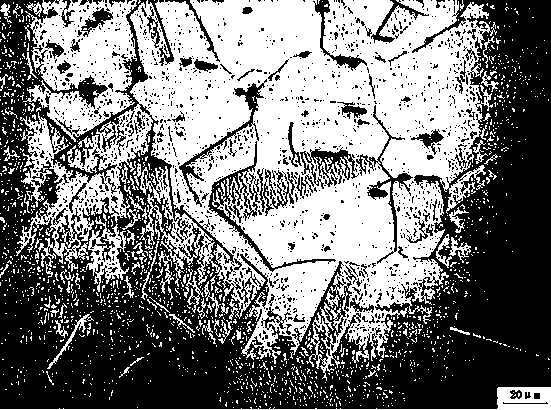

[0034] Embodiment 1. An austenitic stainless steel for electronic products, comprising the following elements by weight: C: 0.023%, Mn: 1.400%, Si: 0.500%, P: 0.019%, S: 0.001%, Cr: 17.250% , Ni: 13.600%, Mo: 2.600%, Cu: 0.035%, N: 0.085%, O: 0.0026%, the balance is Fe and other uncontrollable elements brought from raw materials. Its metallographic structure is as follows figure 1 As shown in the figure, it can be seen from the structure that the solid solution state structure is a single-phase austenite structure.

[0035] The preparation method is as follows:

[0036] A. Smelting and casting: two-step smelting by electric furnace + AOD furnace, when the molten steel composition reaches the design target value, use 350 meters of Si-Ca-Ba wire for calcium treatment before weak blowing in the LF furnace, and adjust the temperature of the tundish to 1500 ℃ , for continuous casting, and electromagnetic stirring is used in the continuous casting process;

[0037] B. Hot rolling...

Embodiment 2

[0043]Embodiment 2. An austenitic stainless steel for electronic products, comprising the following elements by weight: C: 0.025%, Mn: 1.450%, Si: 0.500%, P: 0.020%, S: 0.001%, Cr: 17.000% , Ni: 12.500%, Mo: 2.550%, Cu: 0.030%, N: 0.095%, O: 0.0031%, the balance is Fe and other uncontrollable elements brought from raw materials.

[0044] The preparation method is as follows:

[0045] A. Smelting and casting: two-step smelting by electric furnace + AOD furnace, when the molten steel composition reaches the design target value, use 200 meters of Si-Ca-Ba wire for calcium treatment before weak blowing in the LF furnace, and adjust the temperature of the tundish to 1480 ℃ , for continuous casting, and electromagnetic stirring is used in the continuous casting process;

[0046] B. Hot rolling: 9 passes of rough rolling and 7 passes of finishing rolling are carried out, the temperature of unloading is controlled at 1265 °C, the rolling temperature of finishing rolling is 1050 °C, a...

Embodiment 3

[0051] Embodiment 3. An austenitic stainless steel for electronic products, comprising the following elements by weight: C: 0.024%, Mn: 1.197%, Si: 0.491%, P: 0.019%, S: 0.001%, Cr: 17.430% , Ni: 13.600%, Mo: 2.584%, Cu: 0.300%, N: 0.057%, O: 0.0033%, and the balance is Fe and other uncontrollable elements brought from raw materials.

[0052] The preparation method is as follows:

[0053] A. Smelting and casting: Two-step smelting by electric furnace + AOD furnace, when the molten steel composition reaches the design target value, use 150 meters of Si-Ca-Ba wire for calcium treatment before weak blowing in the LF furnace, and adjust the temperature of the tundish to 1490 ℃ , for continuous casting, and electromagnetic stirring is used in the continuous casting process;

[0054] B. Hot rolling: 9 passes of rough rolling and 7 passes of finishing rolling are carried out, the temperature of the furnace is controlled at 1275 °C, the rolling temperature of finishing rolling is 107...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com