High-strength steel bar with high corrosion resistance and preparation method thereof

A high-corrosion-resistant, high-strength steel technology, applied in the field of alloys, can solve the problem that the comprehensive performance of corrosion resistance and mechanical properties needs to be improved, and achieve the goal of improving oxidation resistance and corrosion resistance, high strength and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

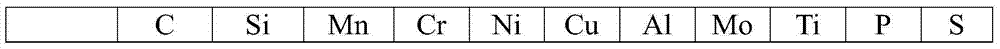

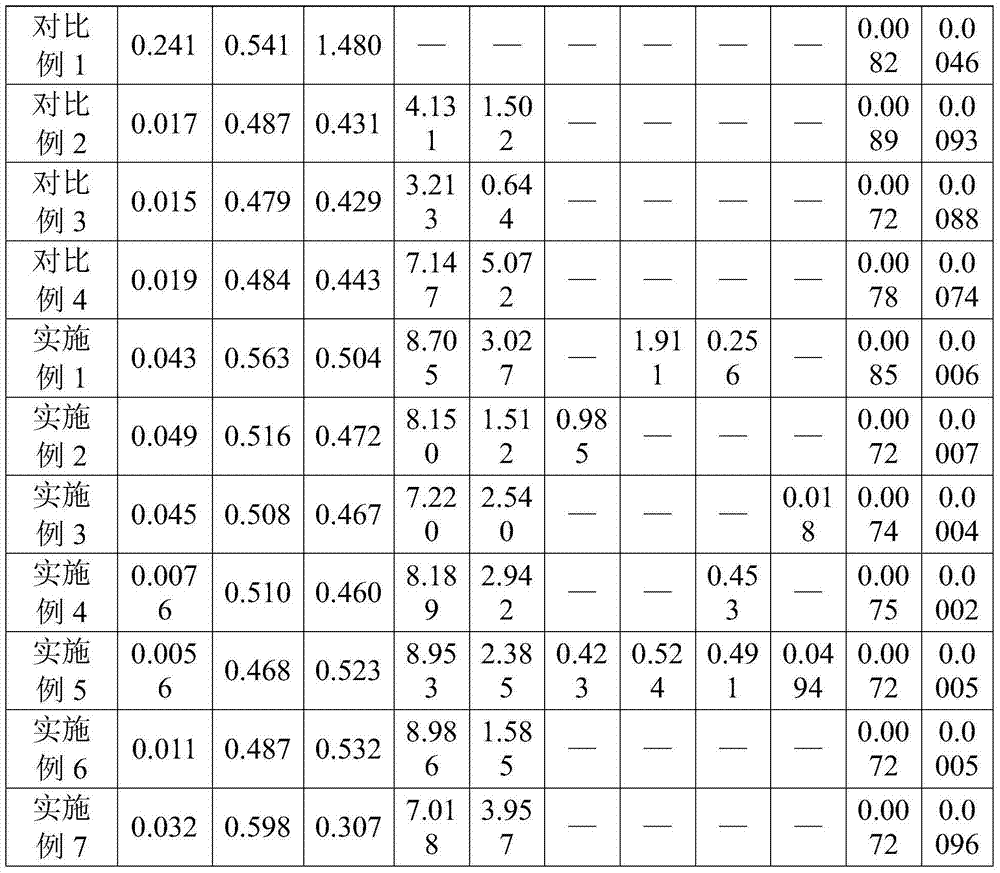

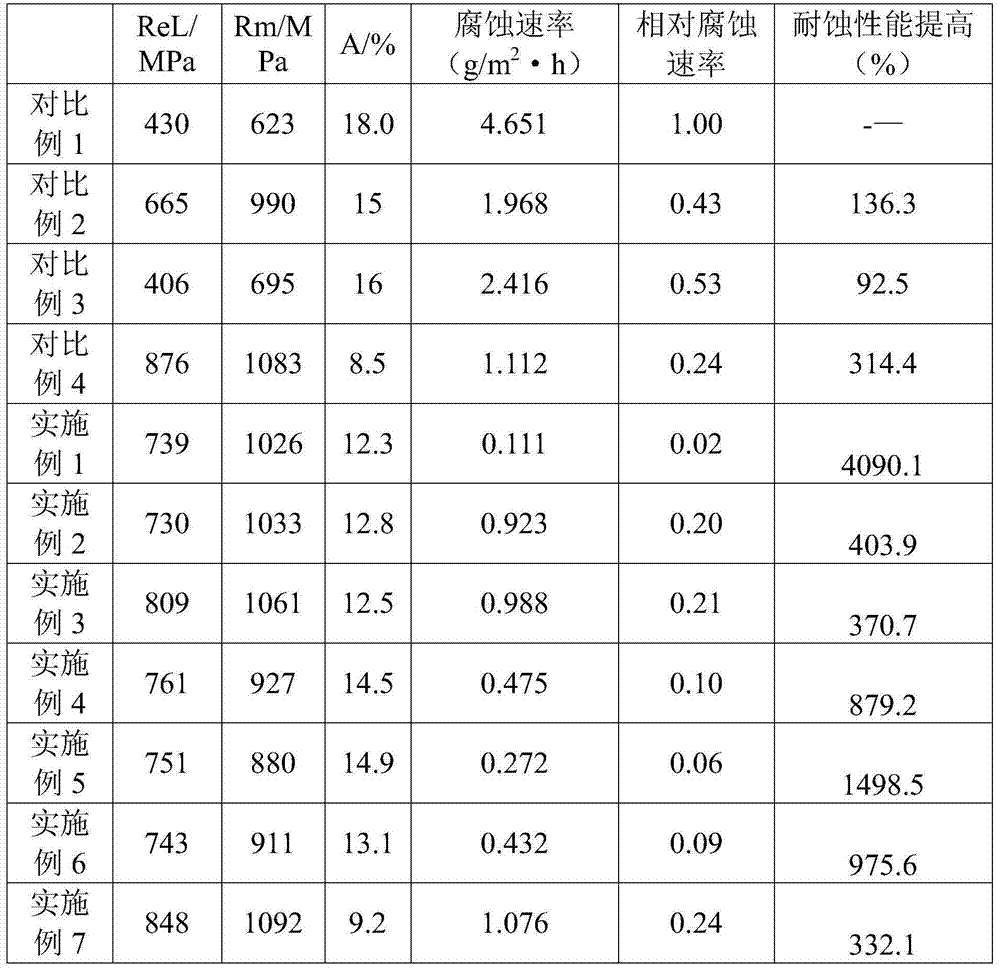

Embodiment 1

[0048] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0049] 1) Desulfurization: Remove blast furnace slag before desulfurization to improve desulfurization efficiency; take iron ore and melt it into molten iron, and the molten iron is desulfurized by KR method, that is, the molten iron is stirred with a stirring paddle at a speed of 90r / min, and after stirring for 2 minutes , add desulfurizer, stir for 10 minutes, and let stand for 5 minutes. Remove the desulfurization slag after the molten iron is desulfurized to stabilize the desulfurization effect, prevent the desulfurization slag from entering the converter and cause the converter to return to sulfur, and ensure that the sulfur content in the steel is controlled below 0.01%.

[0050] Wherein, the desulfurizer is lime powder and fluorite mixed in a mass ratio of 9:1.

[0051] 2) Decarburization, dephosphorization, and deoxidation: smelting in a conver...

Embodiment 2

[0056] The reinforcing bar of the present embodiment, each component is as shown in table 1, and its preparation method is:

[0057] 1) Desulfurization: Remove blast furnace slag before desulfurization to improve desulfurization efficiency; melt iron ore into molten iron, and desulfurize the molten iron using the KR method, that is, stir the molten iron with a stirring paddle at a speed of 110r / min, and stir for 3 minutes , add desulfurizer, stir for 15 minutes, and let stand for 10 minutes. Remove the desulfurization slag after the molten iron is desulfurized to stabilize the desulfurization effect, prevent the desulfurization slag from entering the converter and cause the converter to return to sulfur, and ensure that the sulfur content in the steel is controlled below 0.01%.

[0058] Wherein, the desulfurizer is lime powder and fluorite mixed in a mass ratio of 9:1.

[0059] 2) Decarburization, dephosphorization, and deoxidation: Converter smelting first, top-bottom double...

Embodiment 3

[0064] The steel bar of this embodiment, each component is as shown in the table above, and its preparation method is:

[0065] 1) Desulfurization: Remove blast furnace slag before desulfurization to improve desulfurization efficiency; melt iron ore into molten iron, and desulfurize the molten iron using the KR method, that is, stir the molten iron with a stirring paddle at a speed of 100r / min, and after stirring for 1min , add desulfurizer, stir for 13 minutes, and let stand for 10 minutes. Remove the desulfurization slag after the molten iron is desulfurized to stabilize the desulfurization effect, prevent the desulfurization slag from entering the converter and cause the converter to return to sulfur, and ensure that the sulfur content in the steel is controlled below 0.01%.

[0066] Wherein, the desulfurizer is lime powder and fluorite mixed in a mass ratio of 9:1.

[0067] 2) Decarburization, dephosphorization, and deoxidation: smelting in a converter first, followed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com