Smelting method of high-purity austenitic stainless steel

A technology of pure austenite and smelting method, which is applied in the smelting field of high-purity austenitic stainless steel, can solve the problems of slag adsorption and difficult flotation, and achieve the effect of improving purity and promoting full flotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

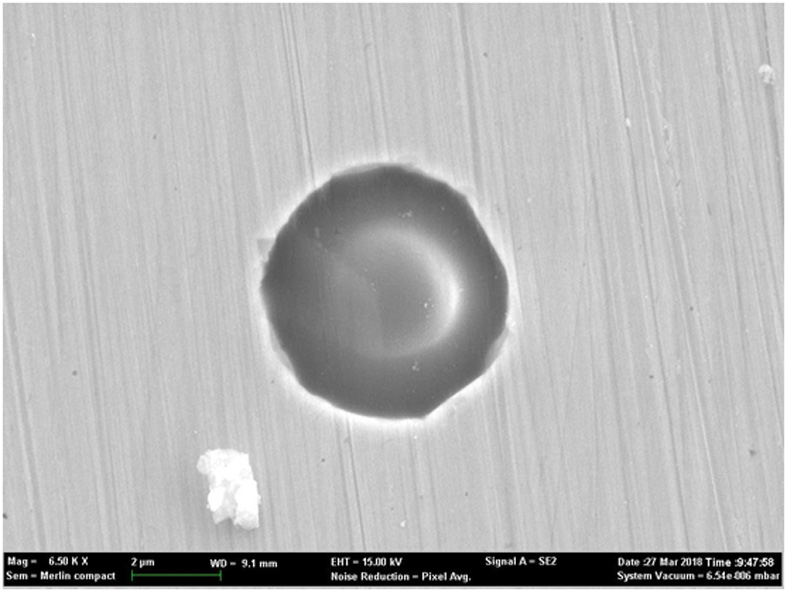

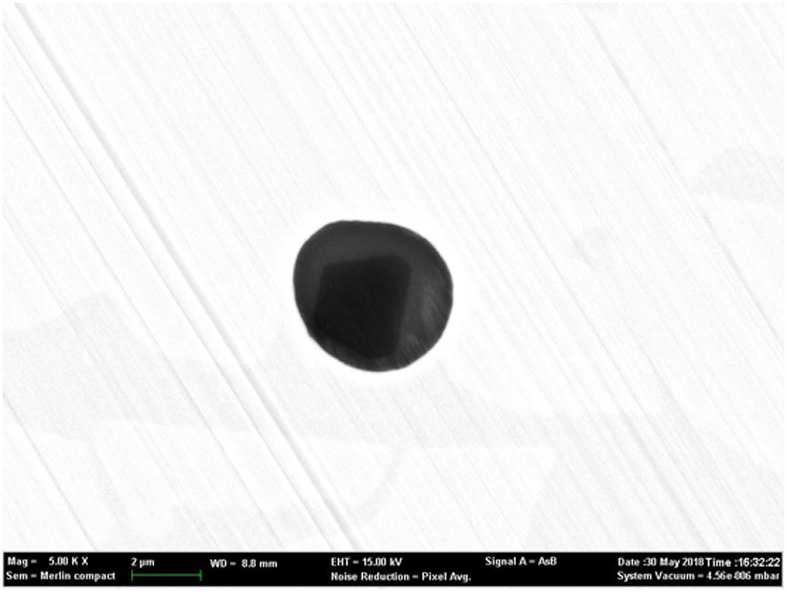

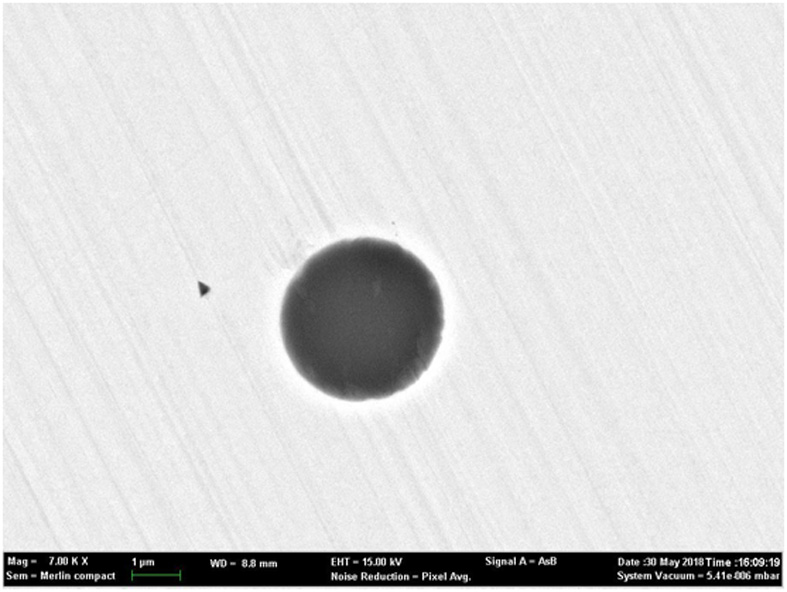

Image

Examples

Embodiment 1

[0025] The smelting method of high-purity austenitic stainless steel, the steel type is specifically 304 austenitic stainless steel, comprising the following steps:

[0026] a. The molten steel is decarburized, reduced and desulfurized in the AOD converter (argon oxygen decarburization converter)

[0027] Inject 90t of molten iron into the AOD converter, and re-blown oxygen on the side top to decarburize in stages. After the oxygen amount reaches the set value, enter the next decarburization period, add high-carbon ferrochrome and lime in batches during the blowing process, and the addition amount is 410kg / t of high-carbon ferrochrome and 120kg / t of lime per ton of molten steel , when the carbon content of molten steel is less than 0.03%, the decarburization period ends, and then add 18kg / t ferrosilicon and 18kg / t fluorite for reduction, and desulfurize after 5 minutes of reduction, add lime 20kg / t in the desulfurization stage, and wait for After the weight percentage reaches...

Embodiment 2

[0036] The smelting method of high-purity austenitic stainless steel, the steel type is specifically 304 austenitic stainless steel, comprising the following steps:

[0037] a. The molten steel is decarburized, reduced and desulfurized in the AOD converter (argon oxygen decarburization converter)

[0038]Inject 95t of molten iron into the AOD converter, and re-blown oxygen on the side top to decarburize in stages. After the oxygen amount reaches the set value, enter the next decarburization period, add high-carbon ferrochrome and lime in batches during the blowing process, and the addition amount is 420kg / t of high-carbon ferrochrome and 130kg / t of lime per ton of molten steel , when the carbon content of molten steel is less than 0.03%, the decarburization period is over, and then 20kg / t ferrosilicon and 20kg / t fluorite are added for reduction, after 5 minutes of reduction, desulfurization is carried out, and lime 22kg / t is added in the desulfurization stage. After the weigh...

Embodiment 3

[0047] The smelting method of high-purity austenitic stainless steel, the steel type is specifically 304 austenitic stainless steel, comprising the following steps:

[0048] a. The molten steel is decarburized, reduced and desulfurized in the AOD converter (argon oxygen decarburization converter)

[0049] Inject 92t of molten iron into the AOD converter, and blow oxygen at the top side to decarburize in stages. According to the carbon content of the molten iron mixed in and the general computer simulation calculation in the steelmaking industry, the amount of oxygen blowing in each stage is determined. After the oxygen amount reaches the set value, it enters the next decarburization period, and high-carbon ferrochrome and lime are added in batches during the blowing process. The addition amount is 412kg / t of high-carbon ferrochrome and 125kg / t of lime per ton of molten steel. , when the carbon content of molten steel is less than 0.03%, the decarburization period is over, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com