Method for improving O-state bending performance of 5083 alloy

A performance and alloy technology, applied in the field of improving the bending performance of 5083 alloy O state, can solve the problem of reducing the bending capacity of 5083 aluminum alloy O state material, and achieve the effect of improving bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

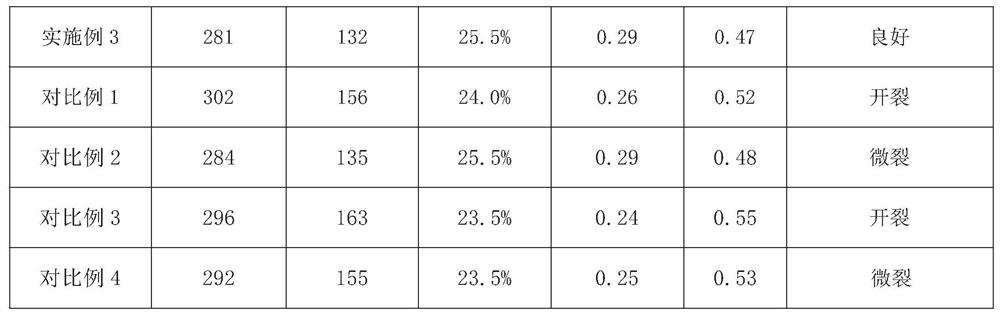

Examples

Embodiment 1

[0029] A method for improving the O-state bending performance of 5083 alloy, characterized in that it comprises the following steps:

[0030] S1, prepare materials, prepare the following component raw materials according to weight percentage: Si≤0.15%, Fe≤0.15%, Cu≤0.05%, Mn=0.40%, Mg=4.3%, Zn≤0.05%, Cr=0.05% , Ti≤0.05%, other individual impurities <0.05%, total impurities <0.15%, and the rest is Al;

[0031] S2, smelting and refining, put the raw materials prepared in step S1 into the melting furnace for smelting, and then obtain molten aluminum after static refining, degassing, slag removal, and filtration. The refining temperature is 730°C, and the online purification treatment requires degassing The hydrogen content measured in the launder is ≤0.1mL / 100gAl, and the content of inclusions in the online launder is less than 0.04mm 2 / kg;

[0032] S3, ingot casting, casting the molten aluminum obtained in step S2 into an aluminum alloy ingot at a casting temperature of 710°C ...

Embodiment 2

[0039] A method for improving the O-state bending performance of 5083 alloy, characterized in that it comprises the following steps:

[0040] S1, prepare materials, prepare the following component raw materials according to weight percentages: Si≤0.15%, Fe≤0.15%, Cu≤0.05%, Mn=0.50%, Mg=4.1%, Zn≤0.05%, Cr=0.08% , Ti≤0.05%, other individual impurities <0.05%, total impurities <0.15%, and the rest is Al;

[0041] S2, smelting and refining, put the raw materials prepared in step S1 into the melting furnace for smelting, and then obtain molten aluminum after static refining, degassing, slag removal, and filtration. The refining temperature is 740°C, and the on-line purification treatment requires degassing The hydrogen content measured in the launder is ≤0.1mL / 100gAl, and the content of inclusions in the online launder is less than 0.04mm 2 / kg;

[0042] S3, ingot casting, casting the molten aluminum obtained in step S2 into an aluminum alloy ingot at a casting temperature of 720...

Embodiment 3

[0049] A method for improving the O-state bending performance of 5083 alloy, characterized in that it comprises the following steps:

[0050] S1, prepare materials, prepare the following component raw materials according to the weight percentage: Si≤0.15%, Fe≤0.15%, Cu≤0.05%, Mn=0.45%, Mg=4.2%, Zn≤0.05%, Cr=0.06% , Ti≤0.05%, other individual impurities <0.05%, total impurities <0.15%, and the rest is Al;

[0051] S2, smelting and refining, put the raw materials prepared in step S1 into the melting furnace for smelting, and then obtain molten aluminum after static refining, degassing, slag removal, and filtration. The refining temperature is 735°C, and the launder is controlled during the degassing process Hydrogen content ≤0.1mL / 100gAl, launder inclusion content 2 / kg;

[0052] S3, ingot casting, casting the molten aluminum obtained in step S2 into an aluminum alloy ingot at a casting temperature of 735°C and a casting speed of 55±3mm / min;

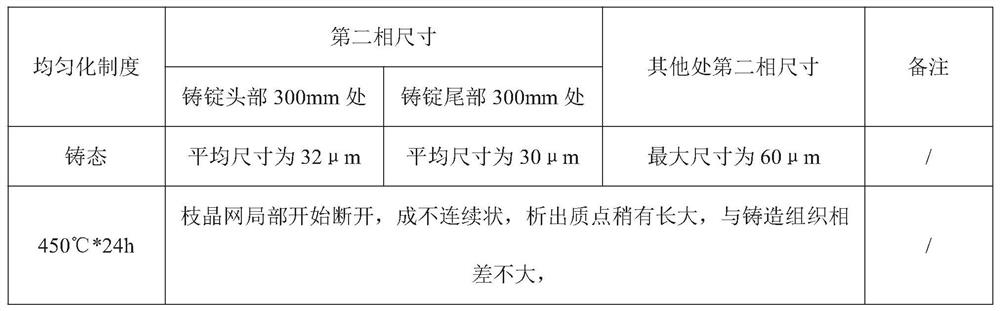

[0053] S4. Homogenizing heat trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com