Patents

Literature

47results about How to "Avoid bending cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

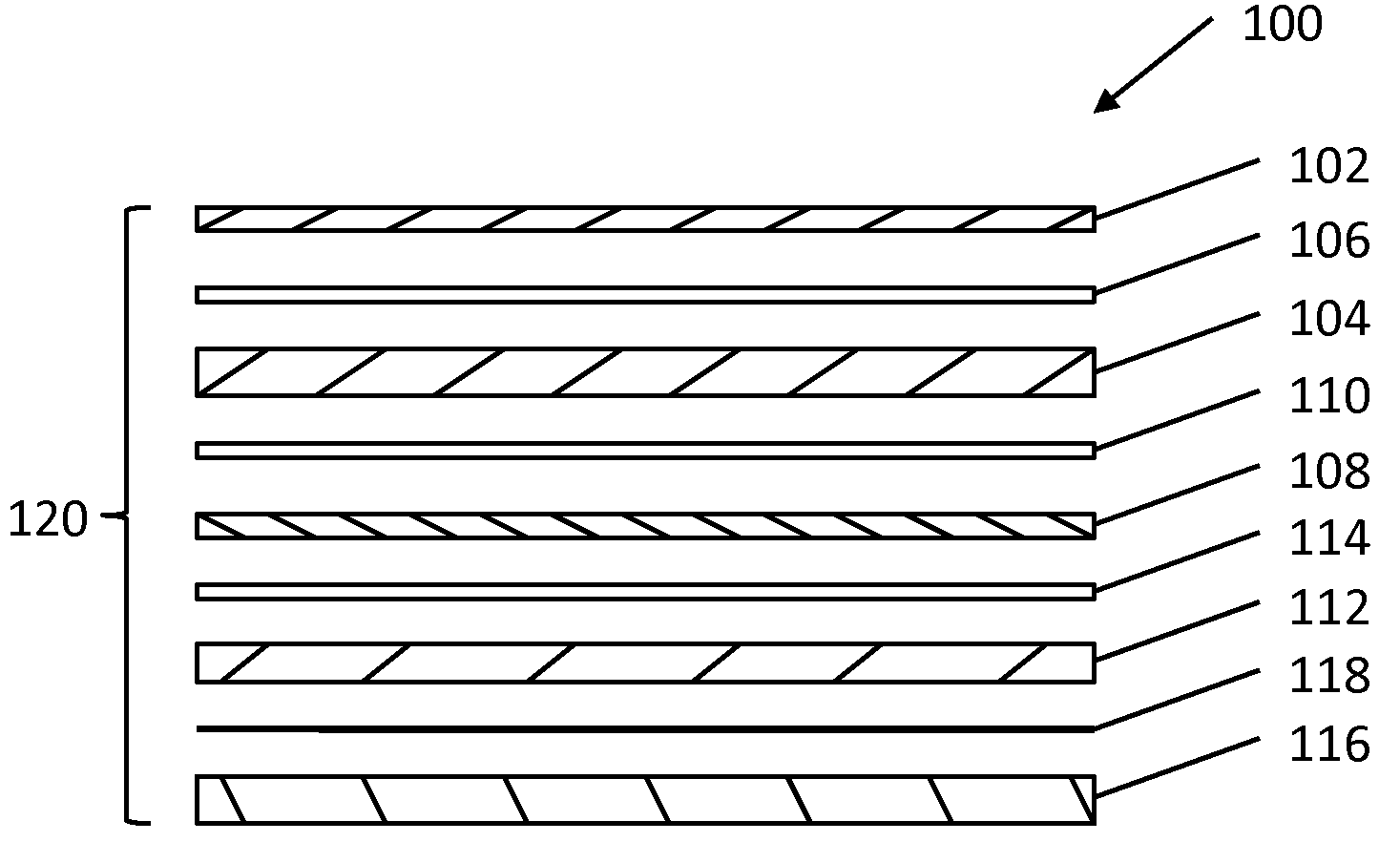

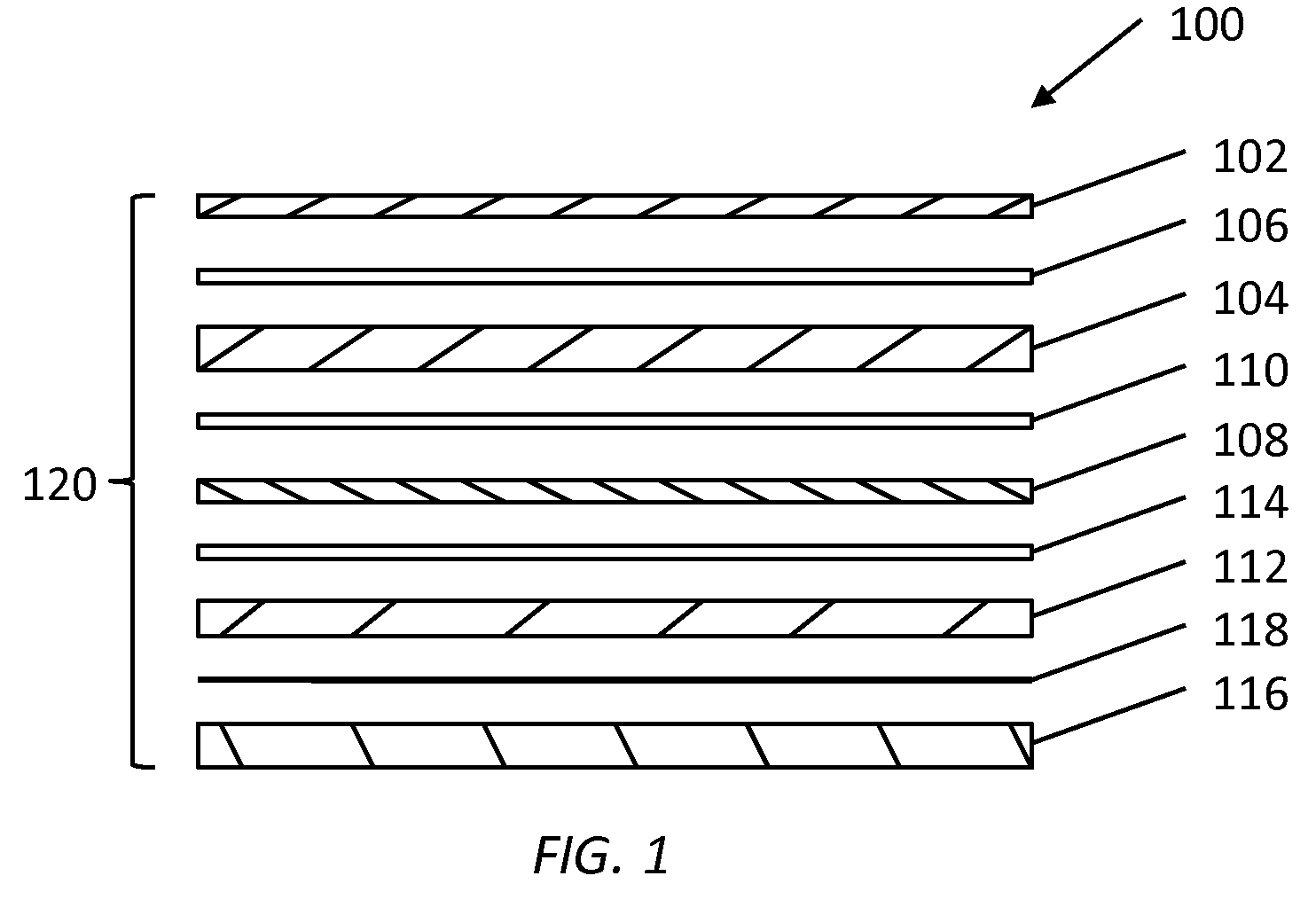

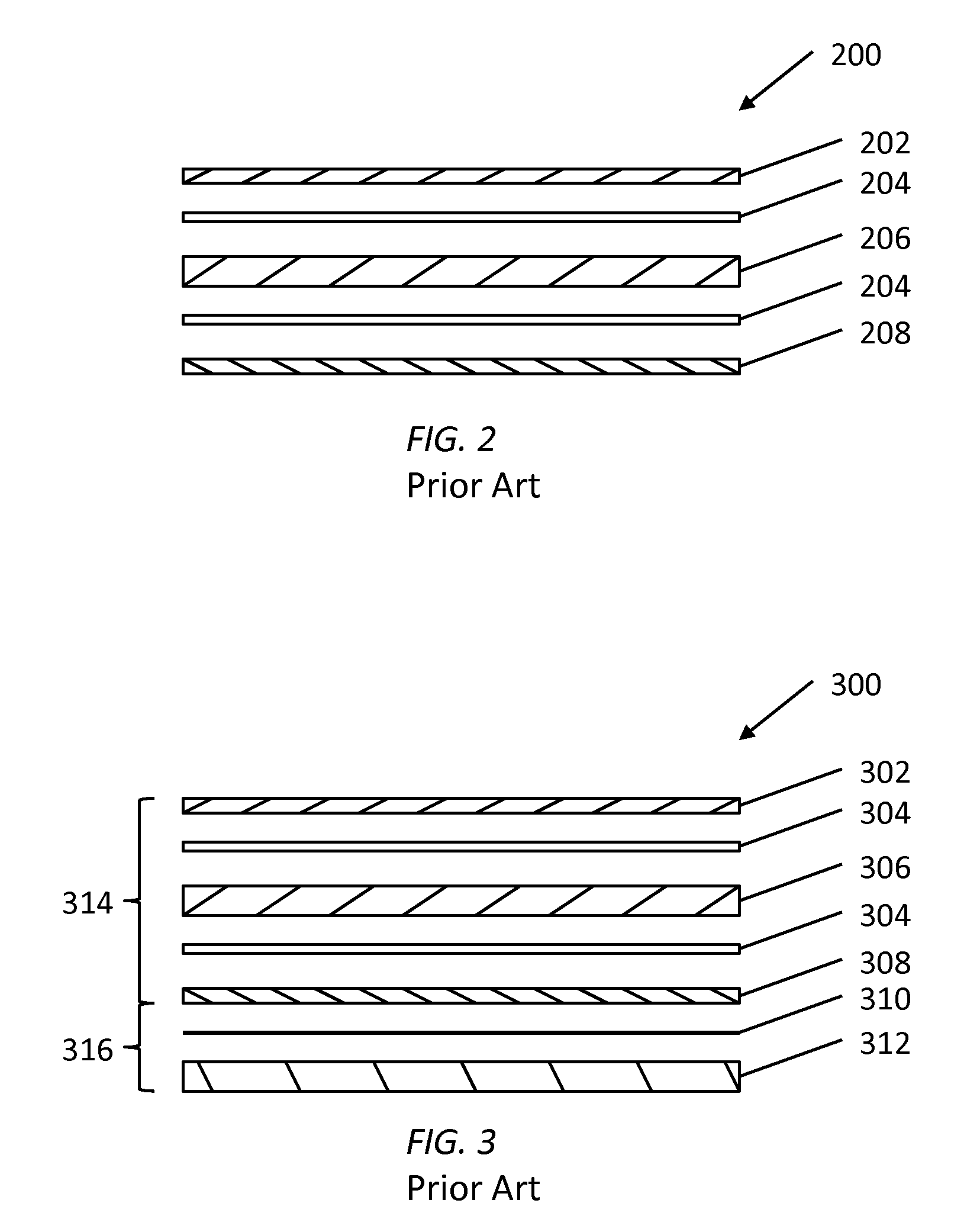

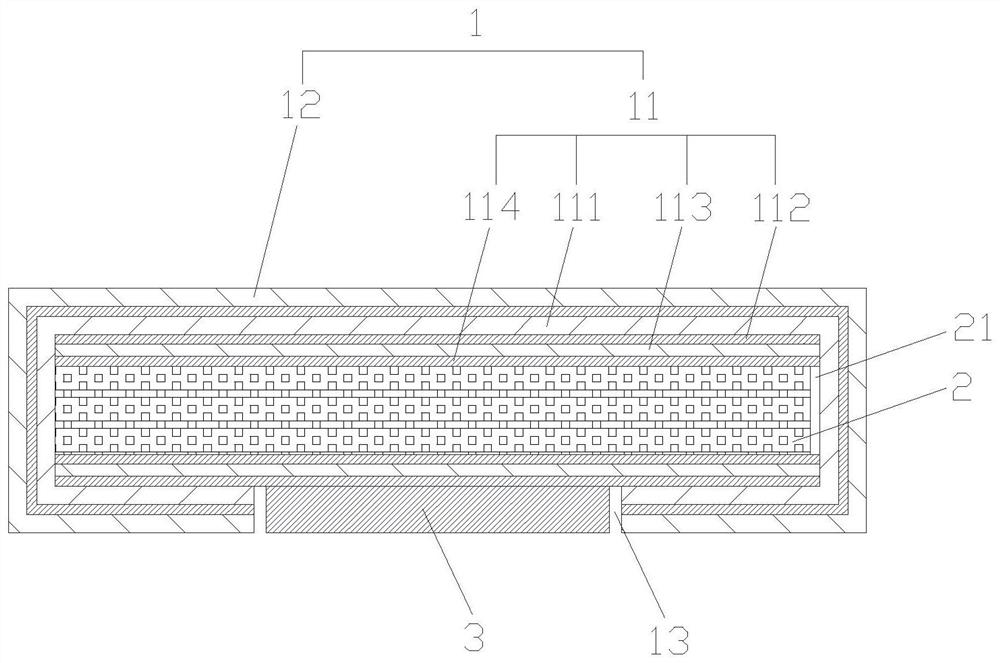

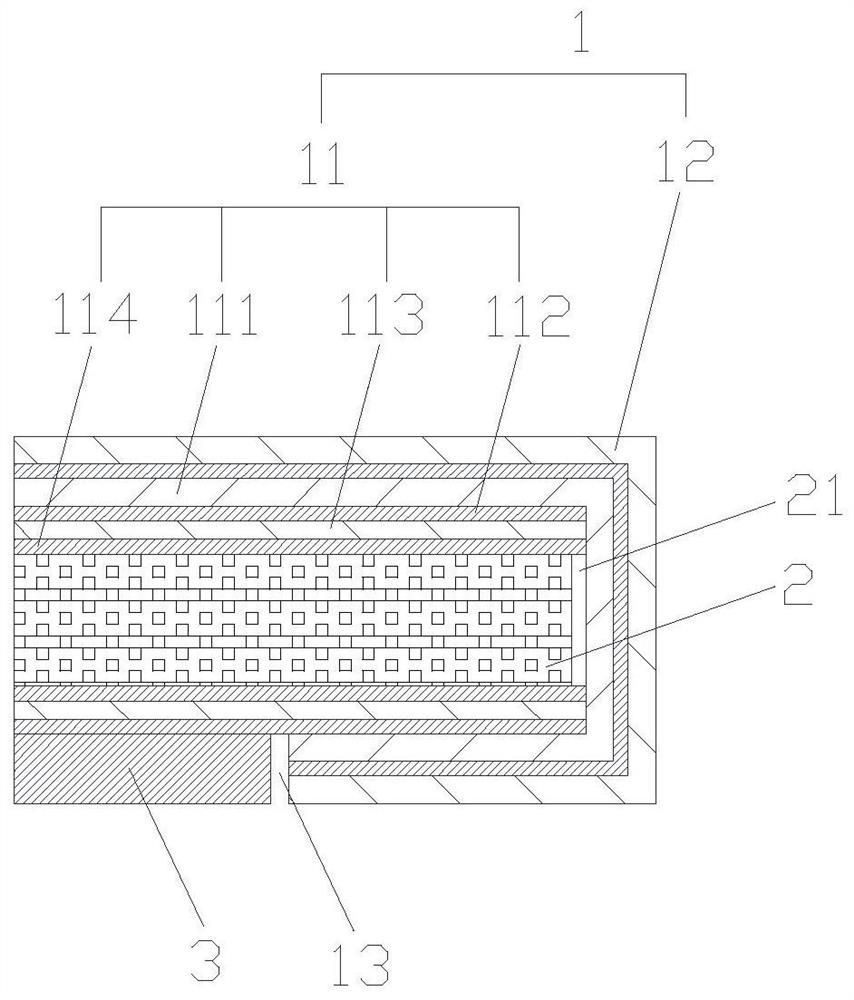

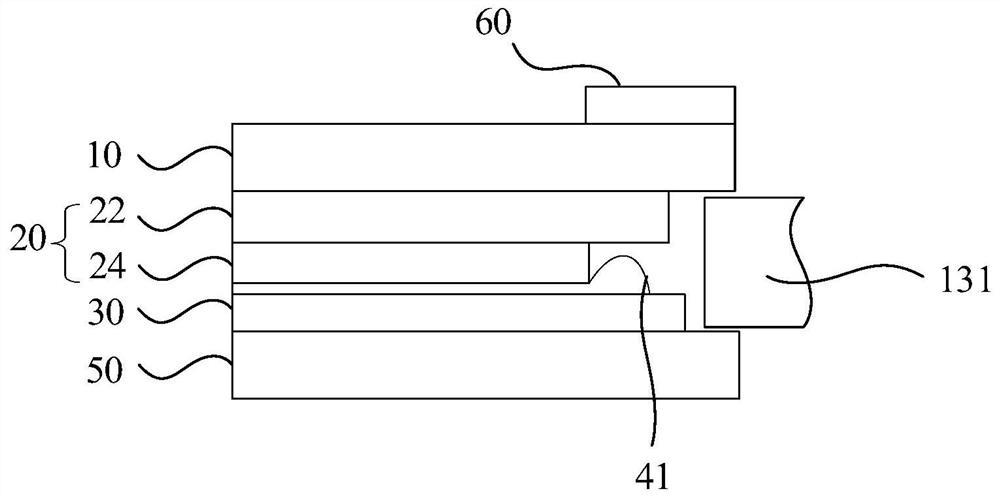

Non-glass photovoltaic module and methods for manufacture

InactiveUS20090272436A1Avoid bendingAvoid crackingSemiconductor/solid-state device manufacturingPhotovoltaic energy generationGlass coverEngineering

A non-glass photovoltaic module including a non-glass cover layer, a photovoltaic layer, a back protection sheet layer, and a support layer, wherein the layers are adhesively bonded together to form a lamination.

Owner:CHEUNG OSBERT HAY

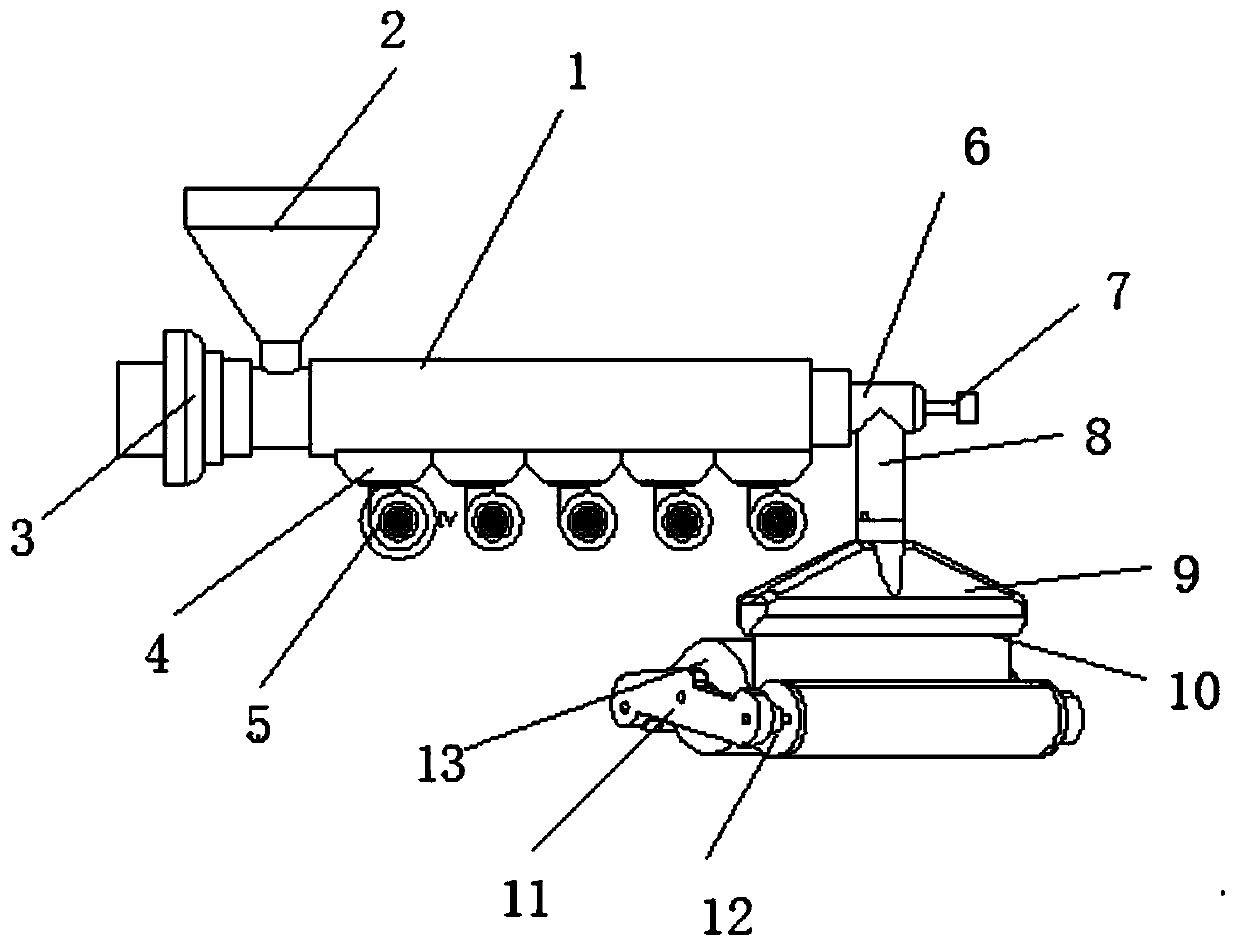

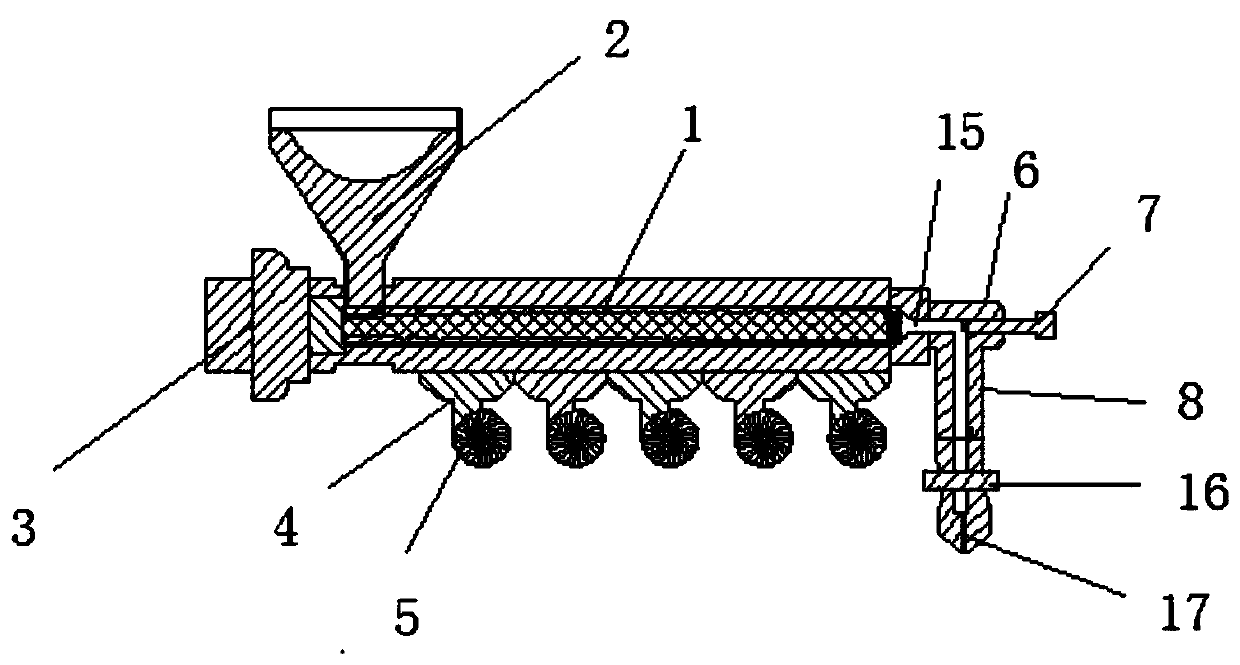

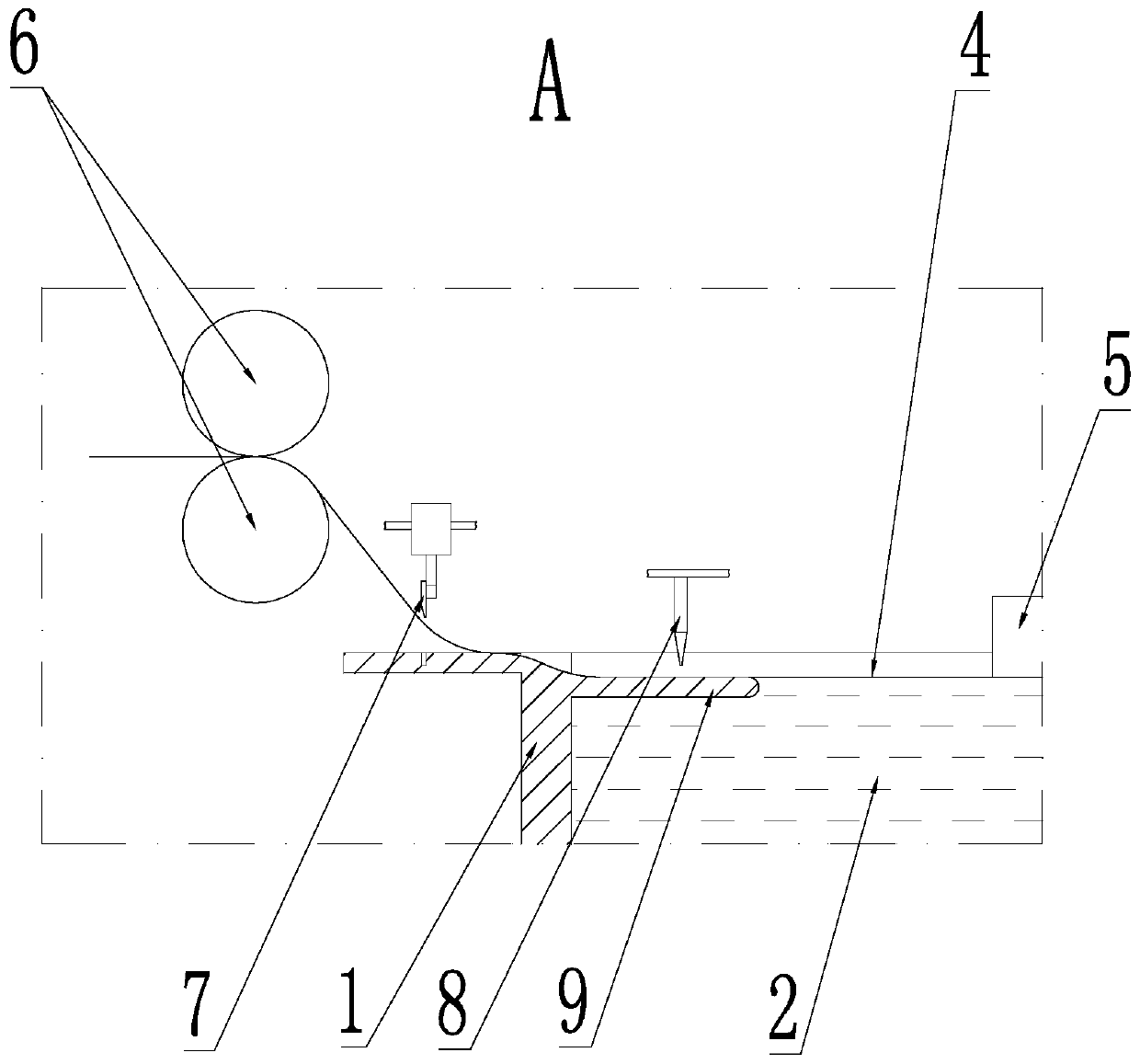

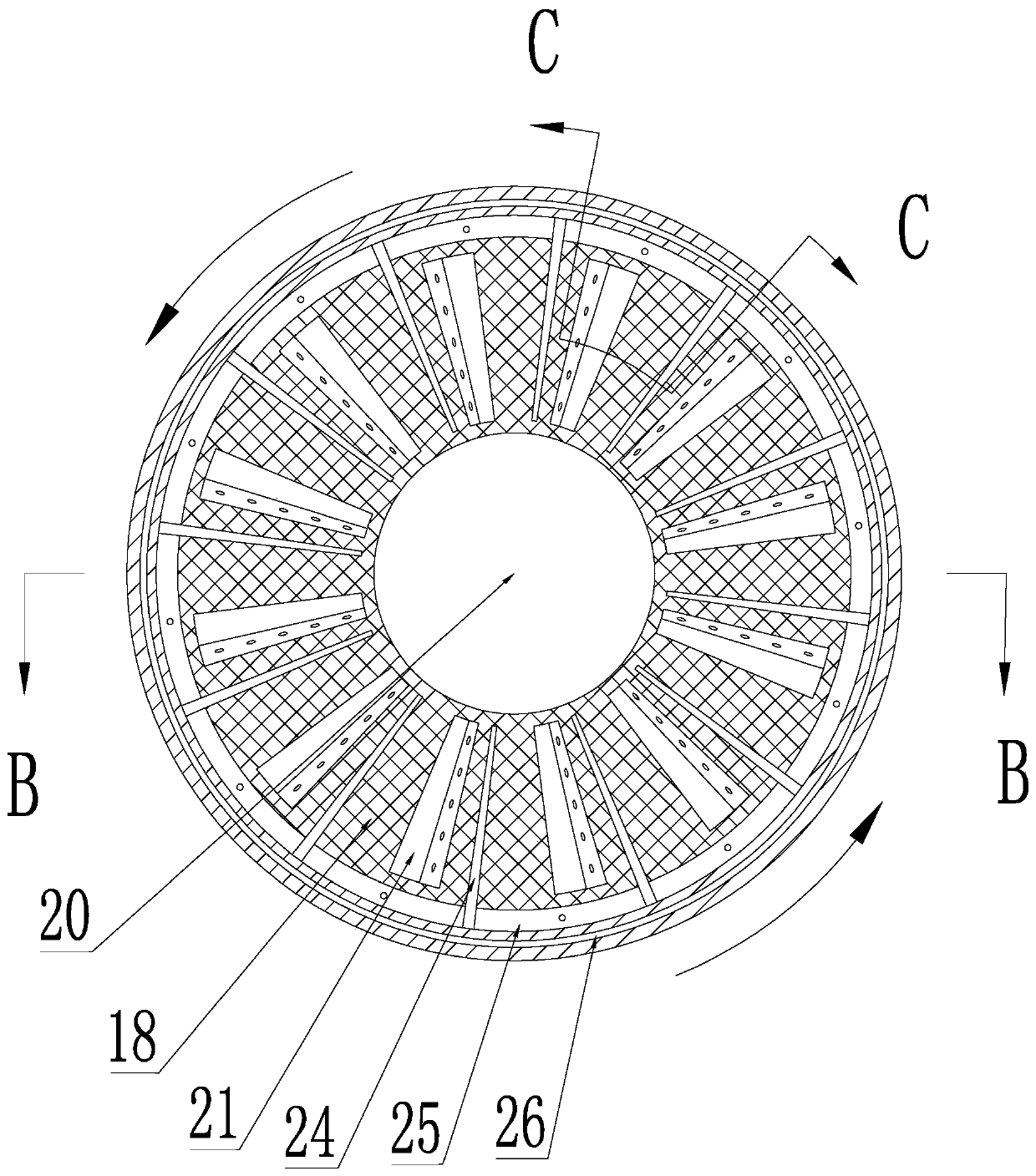

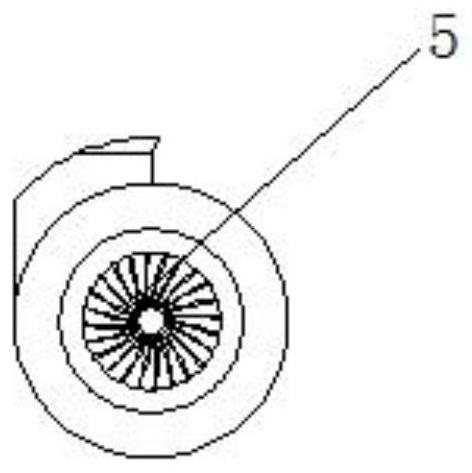

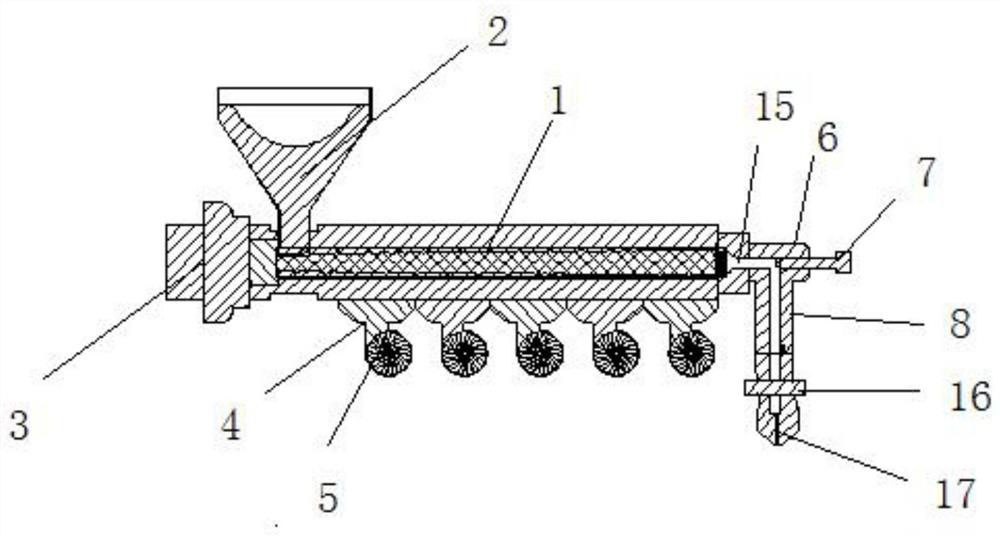

Production process of aluminum-plastic plate

ActiveCN110281635AIncrease pit heat pit combustion performanceQuality improvementLamination ancillary operationsLaminationSurface finishHalogen

The invention discloses a production process of an aluminum-plastic plate. The process comprises mixing and stirring, extrusion molding, degreasing treatment, formation treatment, coating treatment, compounding treatment and trimming treatment. A non-halogen flame retardant and a defoaming agent are added in the preparation process of a plastic core plate; the heat and burning resistant properties of an aluminum-plastic plate part can be greatly increased by the non-halogen flame retardant; the surface smooth finish of the prepared plastic core plate can be higher by adding the defoaming agent; the plastic core plate is prevented from generating bubbles in the preparation process; the quality of the produced aluminum-plastic plate part is effectively improved; blank extruded through an extruder barrel flows into a wedge-shaped material guiding cavity, and falls into a preforming compressing device through a strip-shaped outlet of the wedge-shaped material guiding cavity; the preformed compressing device extrudes the inner blank into a plate-like structure by a water-cooling pressing roller I and a water-cooling pressing roller II; then the preliminarily molded plastic core plate is introduced into a subsequent water-cooling pressing roller to perform the extrusion shaping to obtain the plastic core plate; the phenomena of bending cracking and the like which easily appear in the one-step shaping process of the plastic core plate are avoided.

Owner:安徽英标新材料科技有限公司

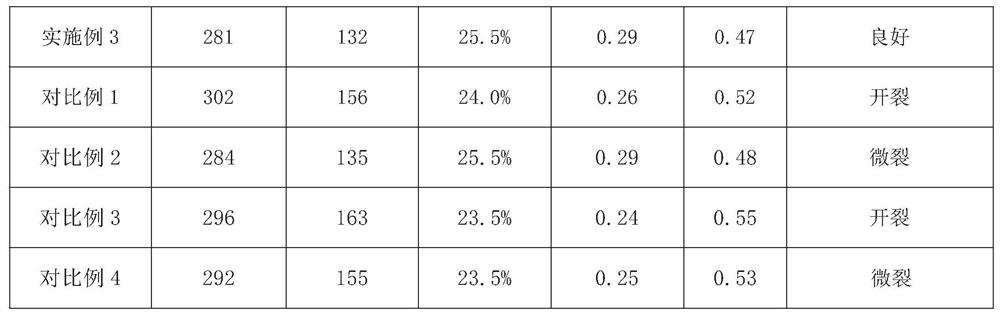

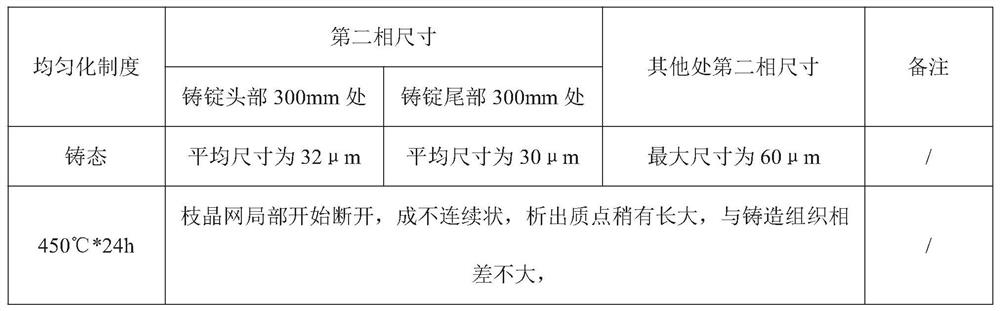

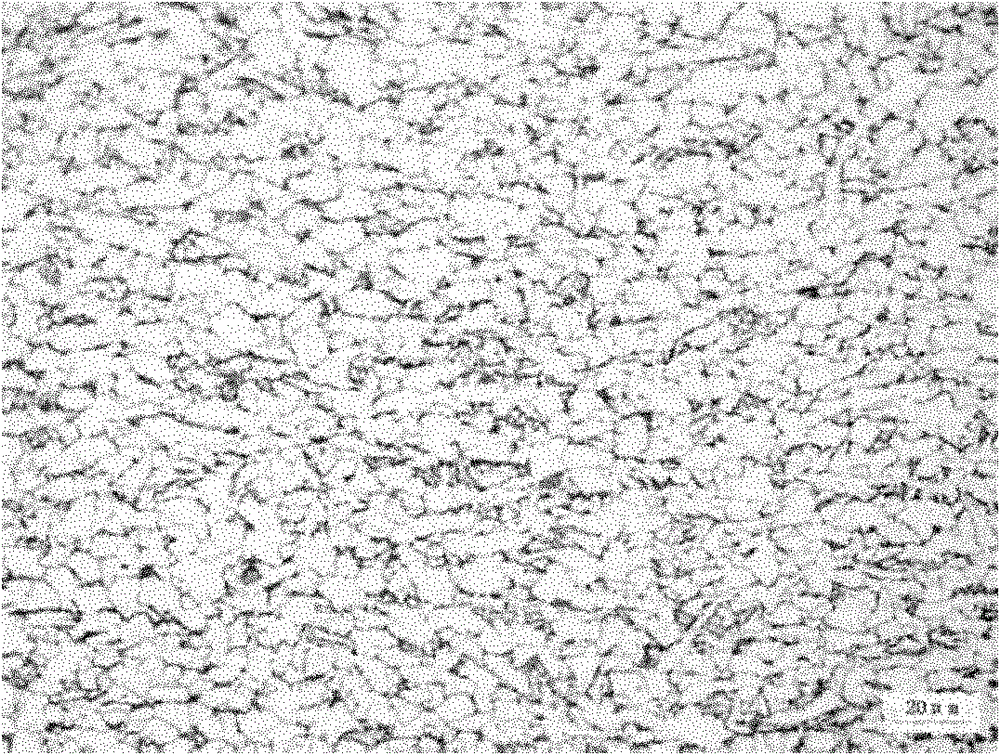

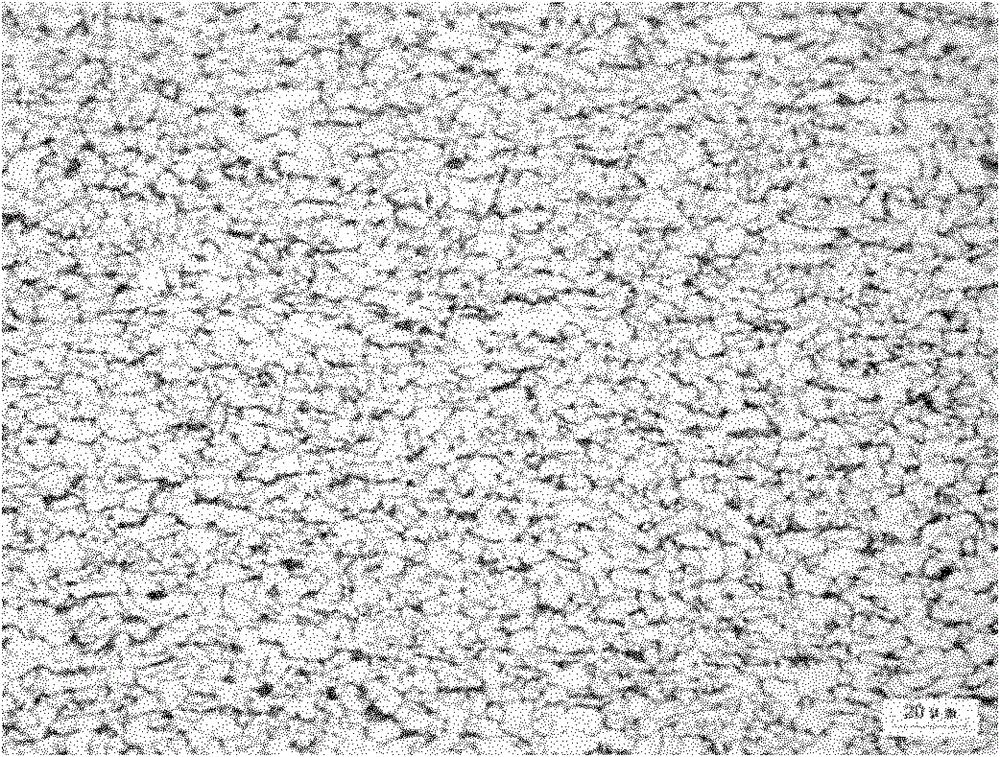

Method for improving O-state bending performance of 5083 alloy

The invention belongs to the technical field of aluminum alloy, and particularly discloses a method for improving the O-state bending performance of 5083 alloy. The method comprises the following steps of: adding prepared raw materials into a smelting furnace for smelting, and standing for refining, degassing, slagging-off and filtering to obtain molten aluminum, wherein the refining temperature is 730-740 DEG C; in the degassing process, controlling the hydrogen content measured by a launder to be less than or equal to 0.1 mL / 100g Al, and controlling the inclusion content of melt in an online launder to be less than 0.04 mm < 2 > / kg; casting the molten aluminum into an aluminum alloy cast ingot at the casting temperature of 710-720 DEG C and the casting speed of 45-55 mm / min; carrying out homogenization heat treatment on the aluminum alloy cast ingot; after preheating, sequentially carrying out multi-pass hot rough rolling and single-pass hot finish rolling to obtain a hot-rolled blank with the thickness of 10.0-12.0 mm; carrying out cold rolling on the hot-rolled blank at the high reduction rate to obtain a cold-rolled coiled material with the thickness of 3.0-5.0mm; and carrying out high-temperature rapid annealing, transverse shearing, straightening and slitting on the cold-rolled coiled material to obtain an aluminum alloy plate. The minimum relative bending radius of 90-degree bending of the 5083 alloy O-state plate can reach 0.5 t, and the surface is uniform, smooth and fine after bending.

Owner:河南明晟新材料科技有限公司

Method for producing hot-rolled steel coil

InactiveCN102127679AImprove plasticityImprove toughnessProcess efficiency improvementInsertion depthNitrogen

The invention relates to a method for producing a hot-rolled steel coil, which comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching nitrogen and argon, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein the content of the molten steel in a continuously cast intermediate ladle is controlled to be between 8 and 15t and the liquid level is controlled to be between 200 and 350mm when the intermediate ladle is not poured; and pouring is protected in the whole process, and the insertion depth of a long nozzle is between 300 and 400mm; 3) heating the plate blank; and 4) rolling and curling the heated plate blank. By the method, the content of C and Mn in the components of Q235q-D steel is reduced, the comprehensive performance of the Q235q-D steel is improved by appropriate rolling process and controlled cooling process, and a low-cost and high-performance Q235q-D hot-rolled steel coil is produced.

Owner:NINGBO IRON & STEEL

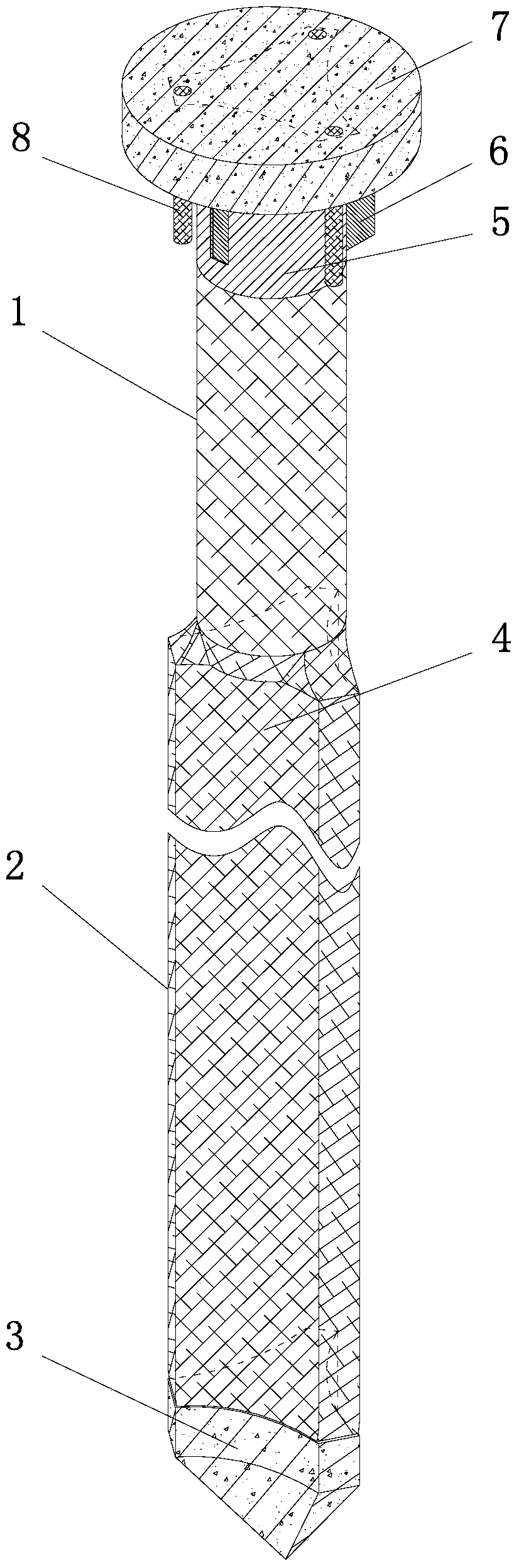

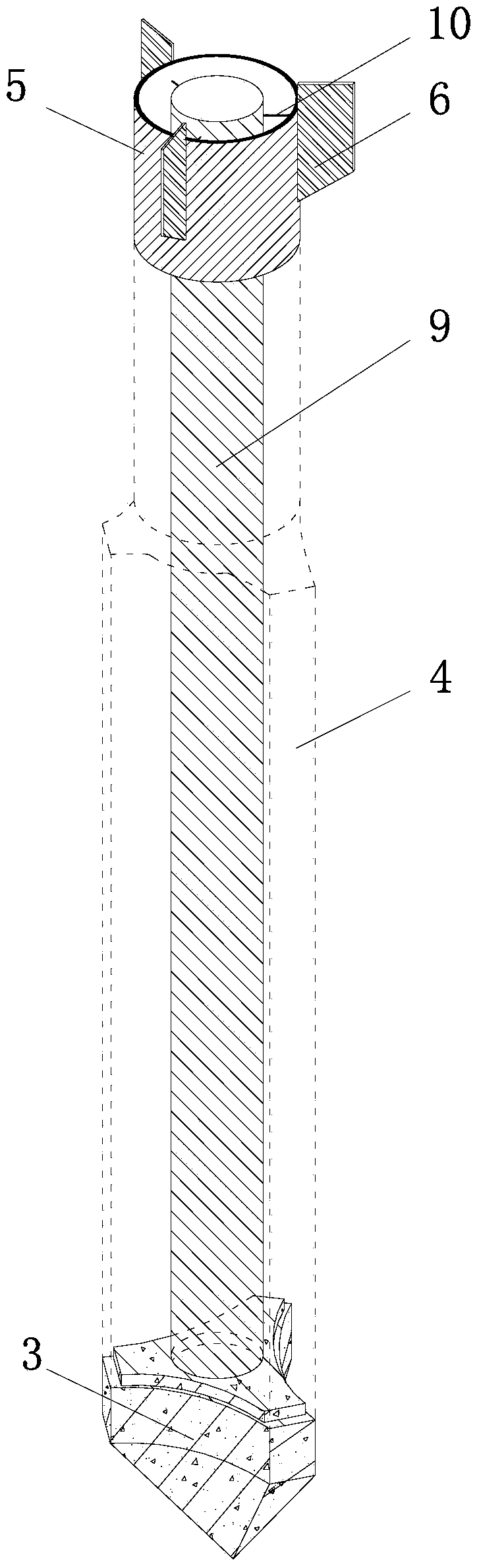

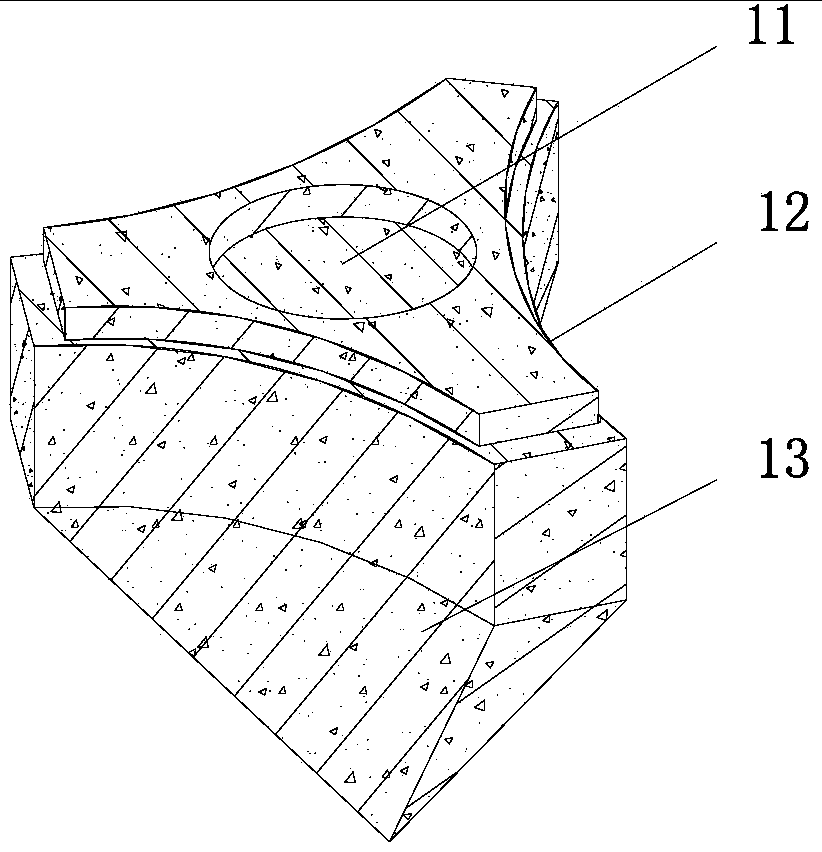

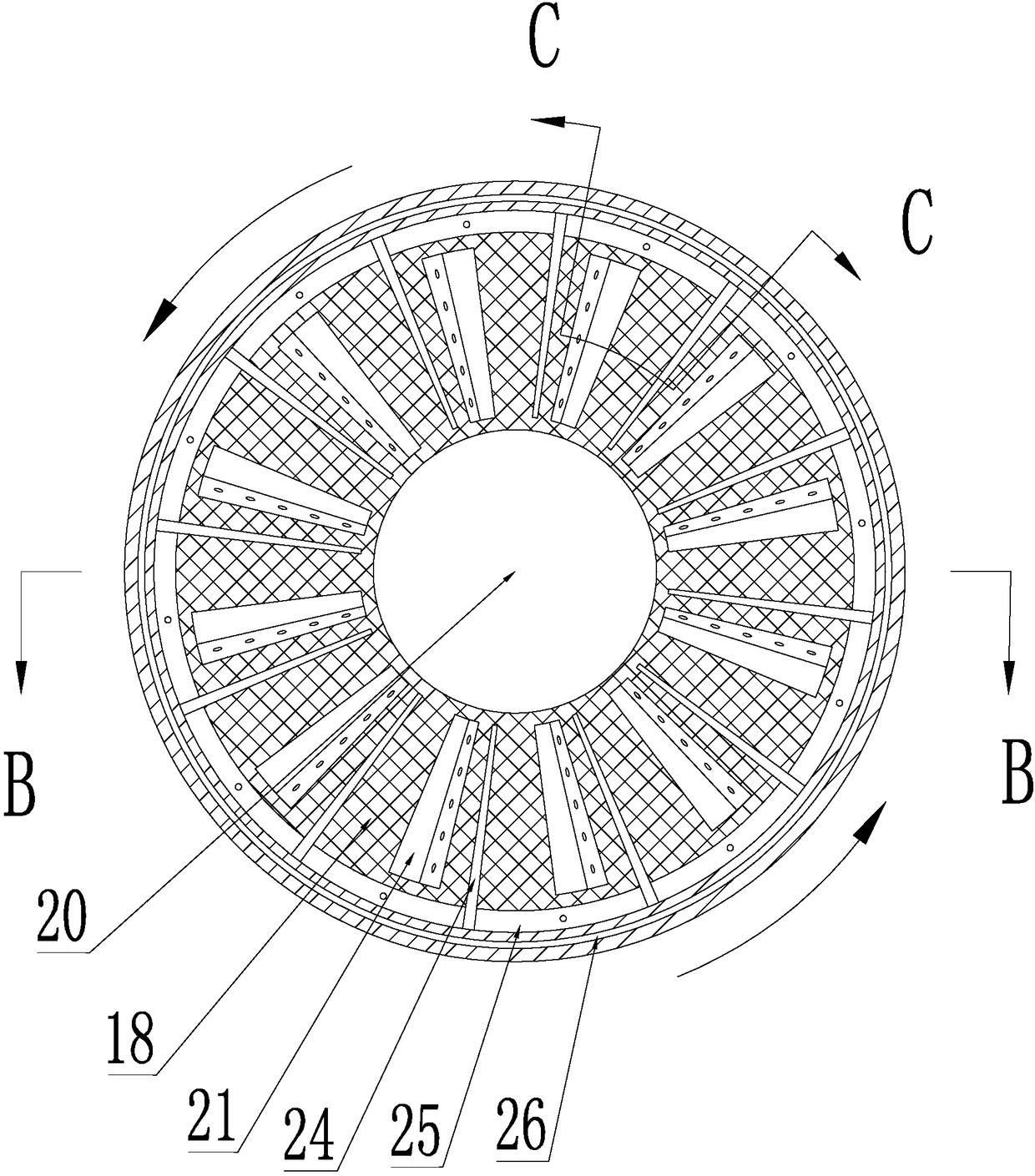

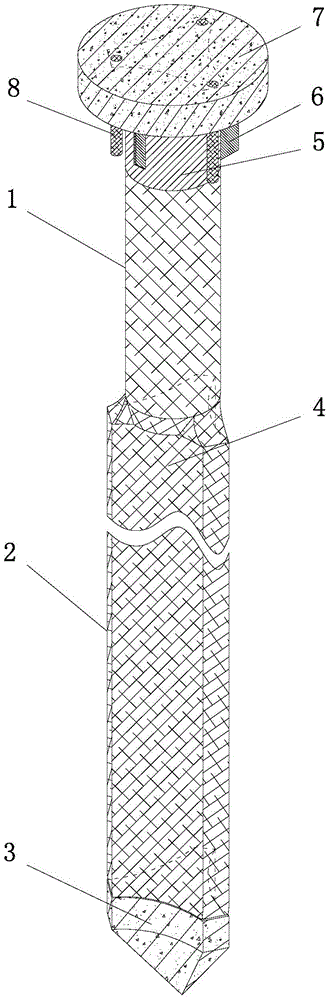

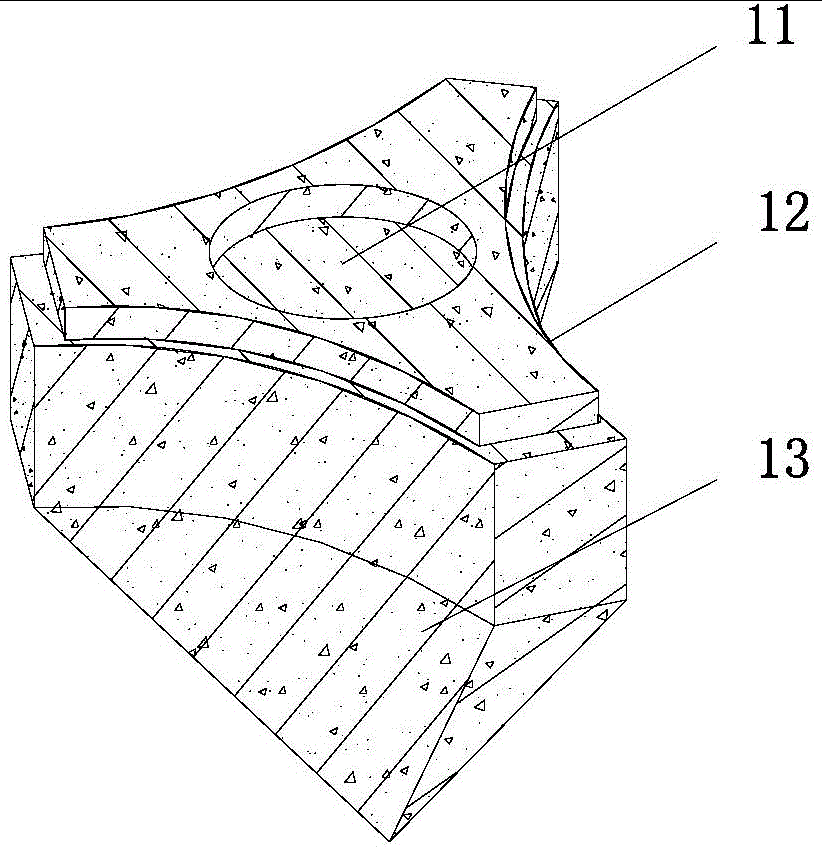

Carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile and construction method thereof

InactiveCN103741682AReduce pile side squeeze effectAccelerate soil consolidationBulkheads/pilesGeotechnical engineeringStructural engineering

The invention relates to a carbon fiber cloth bag cast-in-situ anti-arch curved surface combined irregular-shaped pile, which is characterized in that the upper part of the combined irregular-shaped pile is a round pile body while the lower part thereof is an anti-arch curved surface pile body, and the pile bottom is provided with an irregular-shaped prefabricated pile tip. A carbon fiber cloth bag wraps the outside of the pile body; a steel sleeve with a reinforcing plate is arranged on the top part of the combined irregular-shaped pile; a vertical drain body is filled in the cavity at the outer side of the round pile body; a vertical drain pipe communicated with the vertical drain body is preset in a cast-in-situ cover plate on the top part of the pile. The carbon fiber cloth bag arranged on the outer side of the pile body can reinforce the pile body, improve the stress performance of the pile body and enhance the integrity of the pile body; the section of the pile body on the lower part is an anti-arch curved surface which can prevent influence from excessive fullness of concrete of the pile body to the lateral friction of the pile; the section of the pile body on the upper part is round and can reduce the influence from the lateral negative friction of the pile to the performance of the pile body. The invention also discloses a construction method of the combined irregular-shaped pile.

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

Wrapped heat-conducting grounding elastic piece and electronic device

InactiveCN112351666AHigh strengthImprove thermal conductivityModifications by conduction heat transferConnection contact member materialMetal coatingCopper foil

The invention relates to a wrapped heat-conducting grounding elastic piece and an electronic device, and belongs to the field of conductive components. The wrapped heat-conducting grounding elastic piece comprises a shielding film and a high temperature resistant elastic body, the shielding film is provided with a cavity used for wrapping the elastic body and comprises a supporting film layer anda copper foil layer from inside to outside, and a transition metal layer and a conductive metal layer are sequentially arranged on the outer surface of the copper foil layer from inside to outside. Therefore, according to the wrapped heat conduction grounding elastic piece, by adopting the technical means of improving the strength of the shielding film via the supporting film layer and electroplating the metal layer on the surface of the copper foil layer, the technical problem that a metal coating electroplated on the elastic piece is thinner and is prone to bending and cracking is solved, and the technical effects that a thicker metal plating layer is easy to electroplate, and the metal plating layer cannot be bent or cracked are achieved.

Owner:SHENZHEN JOHAN MATERIAL TECH CO LTD

Preparing method of flexible OLED display screen thin film

ActiveCN106848089AGood effectGuaranteed barrier propertiesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmRadio frequency magnetron sputtering

The invention provides a preparing method of flexible OLED display screen thin film. By adopting an acrylic acid type resin monomer as an organic film raw material, acrylic acid and a derivative monomer are evaporated on a plastic substrate, and are polymerized into film through a curing method, the surface condition of the plastic substrate is improved to make the surface smooth, and through a radio frequency magnetron sputtering method, then an inorganic medium dense film layer is prepared on an organic film to be adopted as a barrier to obstruct water and oxygen. According to the preparing method of the flexible OLED display screen thin film, the technical defects are overcome that in a technology that an existing flexible display device is encapsulated, the protective layer is prone to fractures when adopted to fold the flexible display device, thus the ability to obstruct water and oxygen is lowered by a large margin, and the display effect is influenced. The prepared thin film can effectively obstruct water and oxygen from invading into the display screen, the material is prevented from aging, and the service life of an OLED device is prolonged.

Owner:汇精(厦门)电子科技有限公司

Method for producing hot-rolled steel coils

InactiveCN102212748AReduce dosageSimple methodRoll mill control devicesManufacturing convertersNiobiumPosition control

The invention relates to a method for producing hot-rolled steel coils. The method comprises the following steps of: 1) designing components, pre-treating molten iron, smelting in a converter with nitrogen and argon switching, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein when pouring of a continuously cast intermediate ladle is stopped, the molten steel quantity of the intermediate ladle is controlled at 8 to 15 tons, the liquid level is 200 to 350 millimeters, full-process protective pouring is adopted, and the inserting depth of a long nozzle is 300 to 400 millimeters; 3) heating the plate blank; and 4) rolling the heated plate blank, and coiling. A thermo-mechanical control process + remote position control (TMCP+RPC) rolling process is adopted in the method; by using micro niobium treatment, the content of C and the content of Mn are greatly reduced, and the production cost is reduced; the obtained Q345q-C hot-rolled steel coils have good plasticity and toughness, and the elongation of the steel coils can be improved by over 8 percent; and meanwhile, the welding property of the steel coils is improved, and good surface quality of a continuously cast bloom is ensured.

Owner:NINGBO IRON & STEEL

Method for producing hot rolled steel coils

The invention relates to a method for producing hot rolled steel coils. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the Q345R hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

Low-cost and high-performance SPA-H hot rolled steel coil and preparation method thereof

InactiveCN106947915AImprove plasticityImprove toughnessManufacturing convertersProcess efficiency improvementLaminar coolingPre treatment

The invention relates to a low-cost and high-performance SPA-H hot rolled steel coil and a preparation method thereof. The low-cost and high-performance SPA-H hot rolled steel coil comprises, by mass, 0.07%-0.095% of C, 0.25%-0.35% of Si, 0.38%-0.48% of Mn, 0.085%-0.105% of P, 0.007% of S or the less, 0.25%-0.35% of Cu, 0.08%-0.20% of Ni, 0.50%-0.60% of Cr, 0.015%-0.045% of Als and the balance Fe and inevitable impurities. The preparation method comprises the steps of composition design, hot metal pretreatment, converter smelting, ladle furnace treatment, continuous casting, hot continuous rolling, laminar cooling and reeling, and the SPA-H hot rolled steel coil is obtained. The SPA-H hot rolled steel coil has excellent plasticity and toughness, cold processing performance is improved, the problem of bending cracking of large deformation in the using process of the SPA-H steel coil is avoided, quality objections are reduced, and comprehensive performance of SPA-H steel is improved.

Owner:NINGBO IRON & STEEL

Method for producing hot rolled steel coil

The invention relates to a method for producing a hot rolled steel coil. The method comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching between nitrogen and argon, and performing tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, controlling tundish molten steel amount to be between 8t and 15t and liquid level to be between 200mm and 350mm when a continuous casting tundish stops pouring, and pouring under protection in the entire process, wherein the length of an inserted part of a long nozzle is between 300mm and 400mm; 3) heating the plate blank; and 4) finally rolling the heated plate blank and winding to obtain the hot rolled steel coil. In the method, a thermo mechanical control process (TMCP) and a relaxation-precipitation-control (RPC) rolling process are adopted, and C content and Mn content are greatly reduced by micro niobium treatment, so that production cost is reduced; the Q345q-E hot rolled steel coil produced by the method has high plasticity and toughness, and the elongation rate of the hot rolled steel coil is improved by more than 8 percent; meanwhile, the welding properties of materials are improved, and high surface quality of a continuous casting blank is guaranteed.

Owner:NINGBO IRON & STEEL

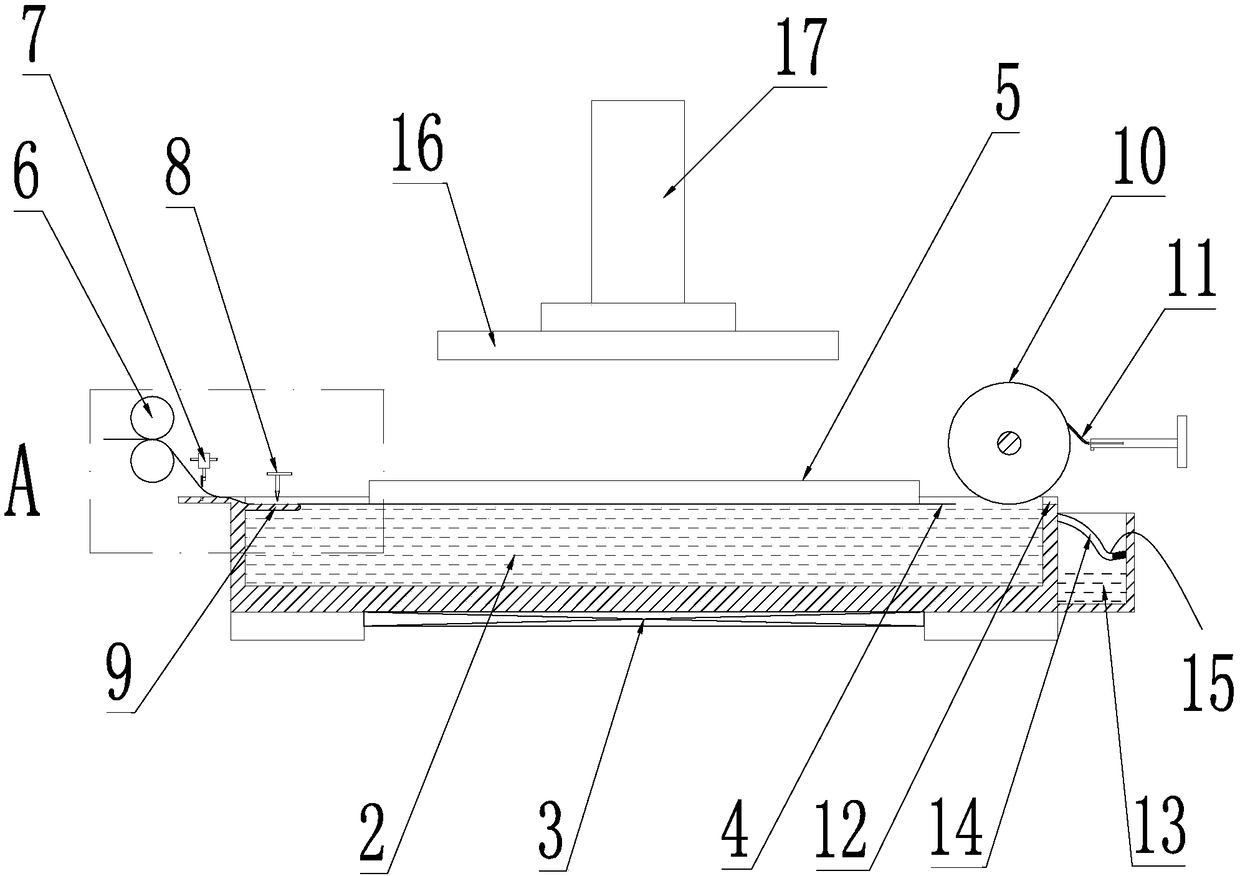

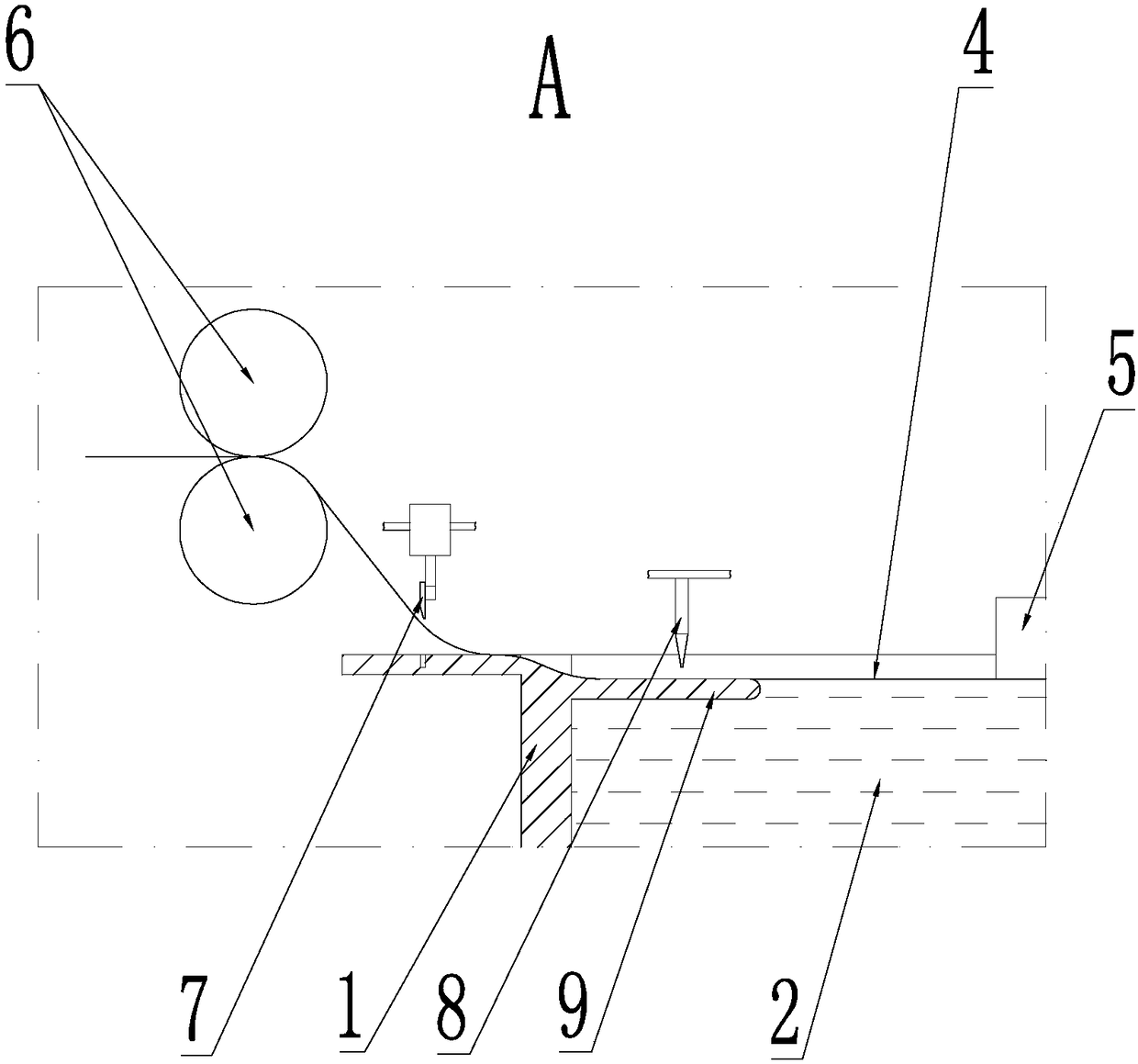

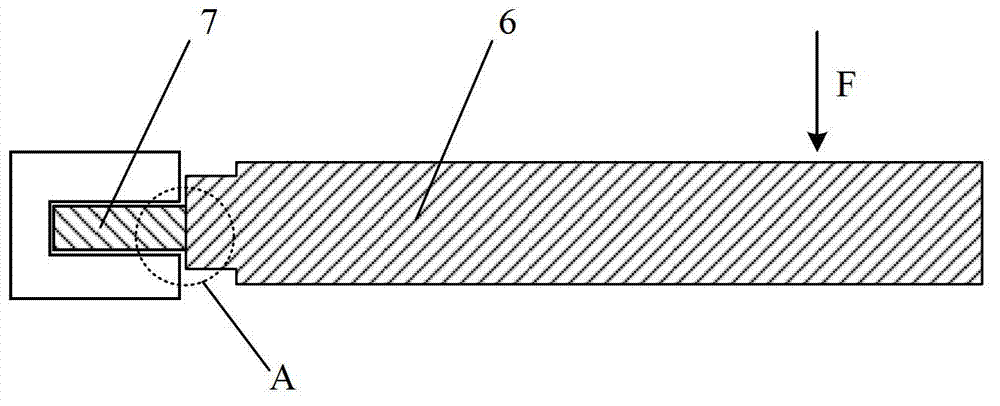

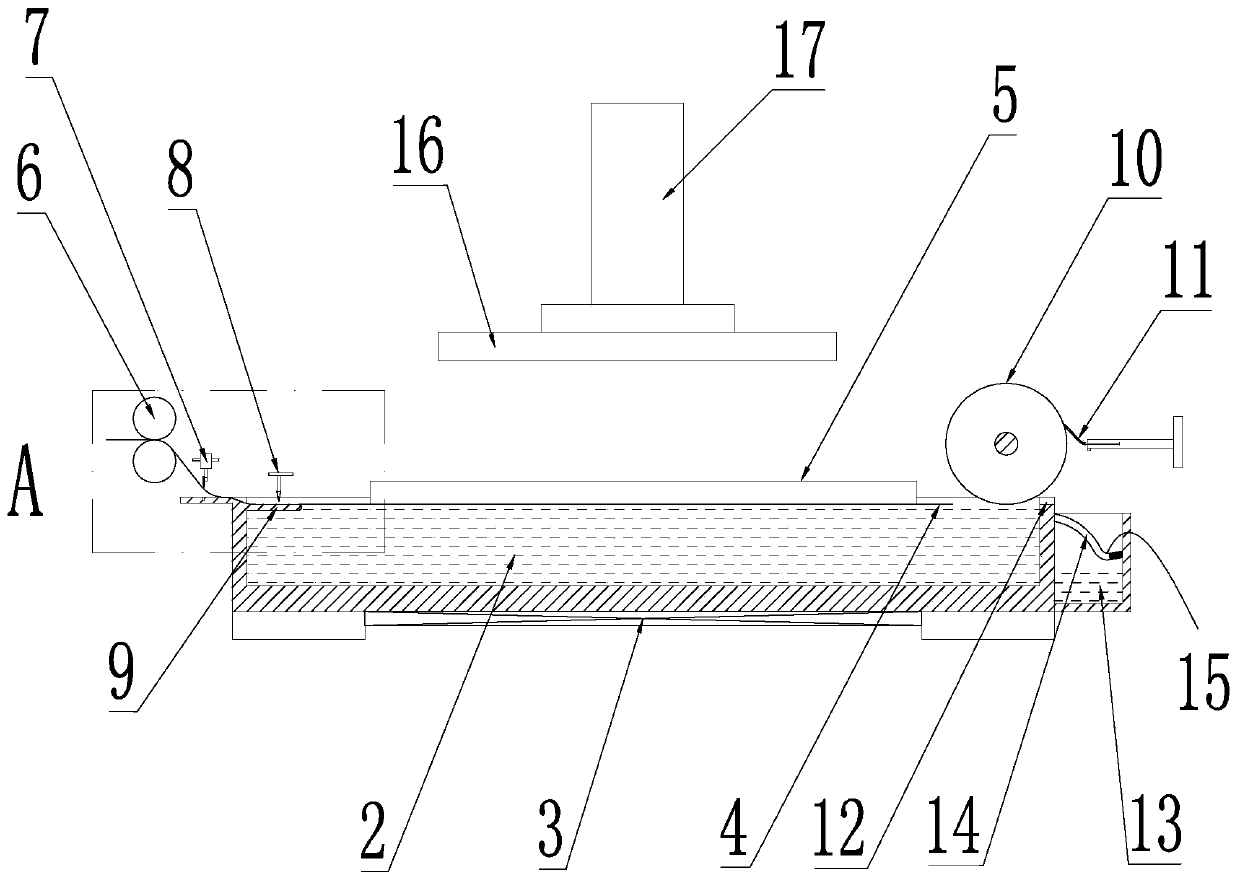

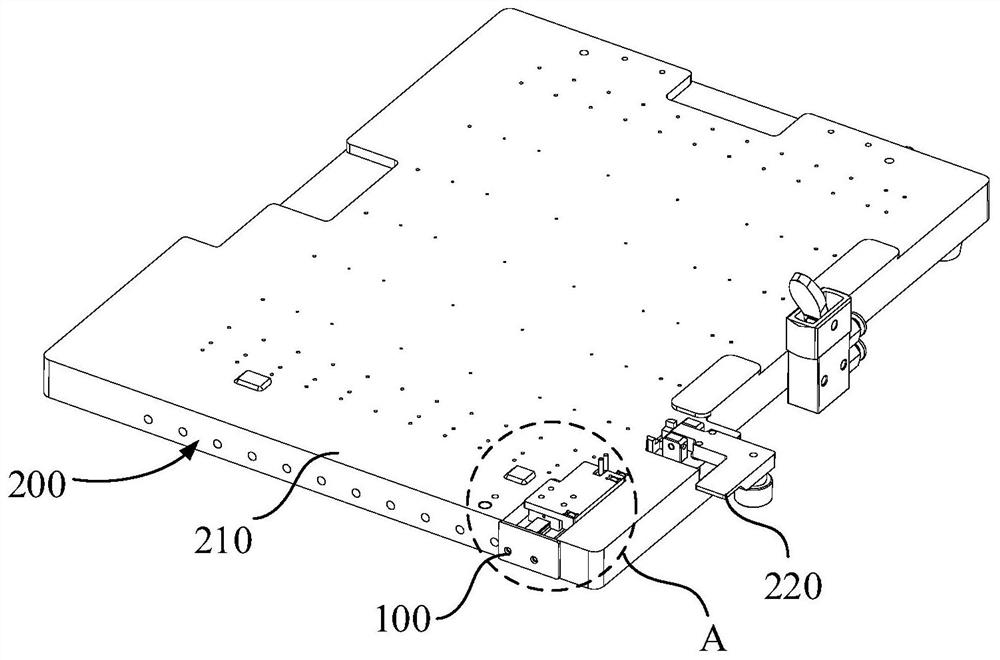

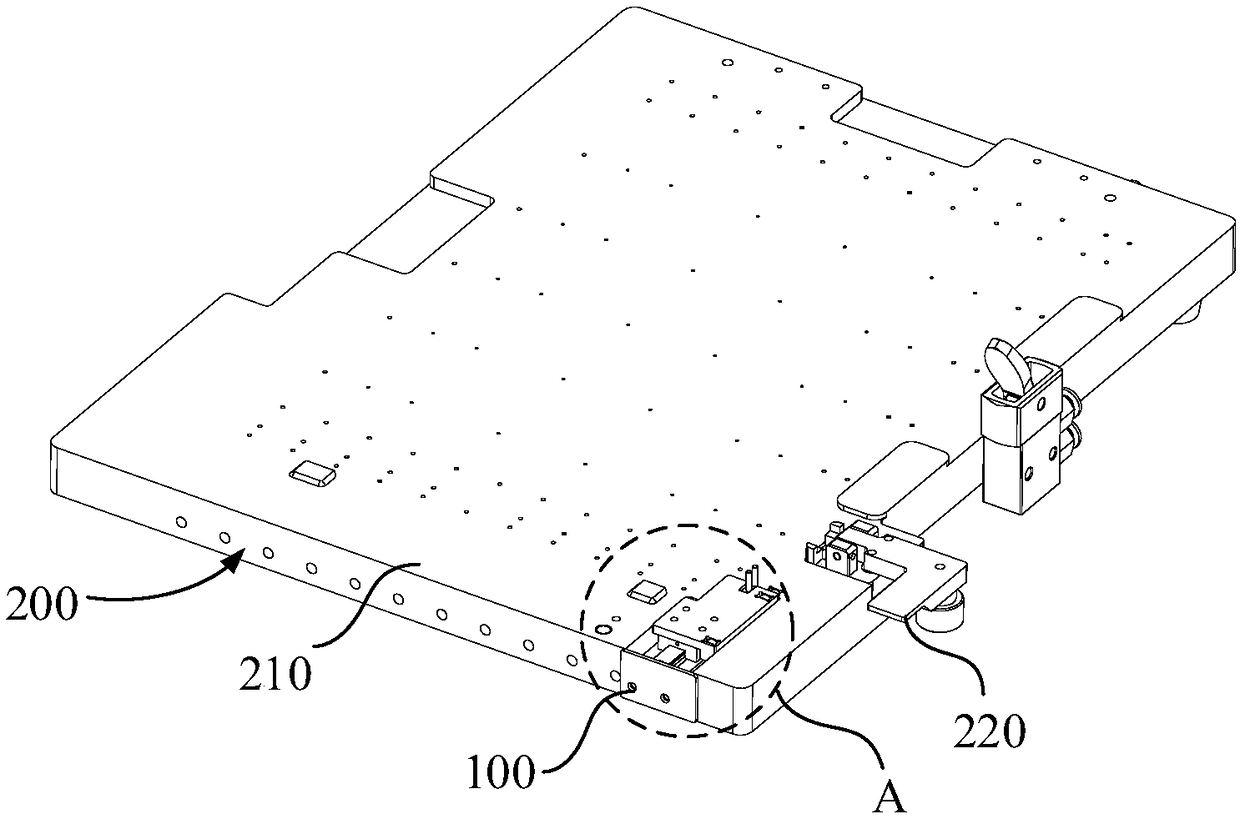

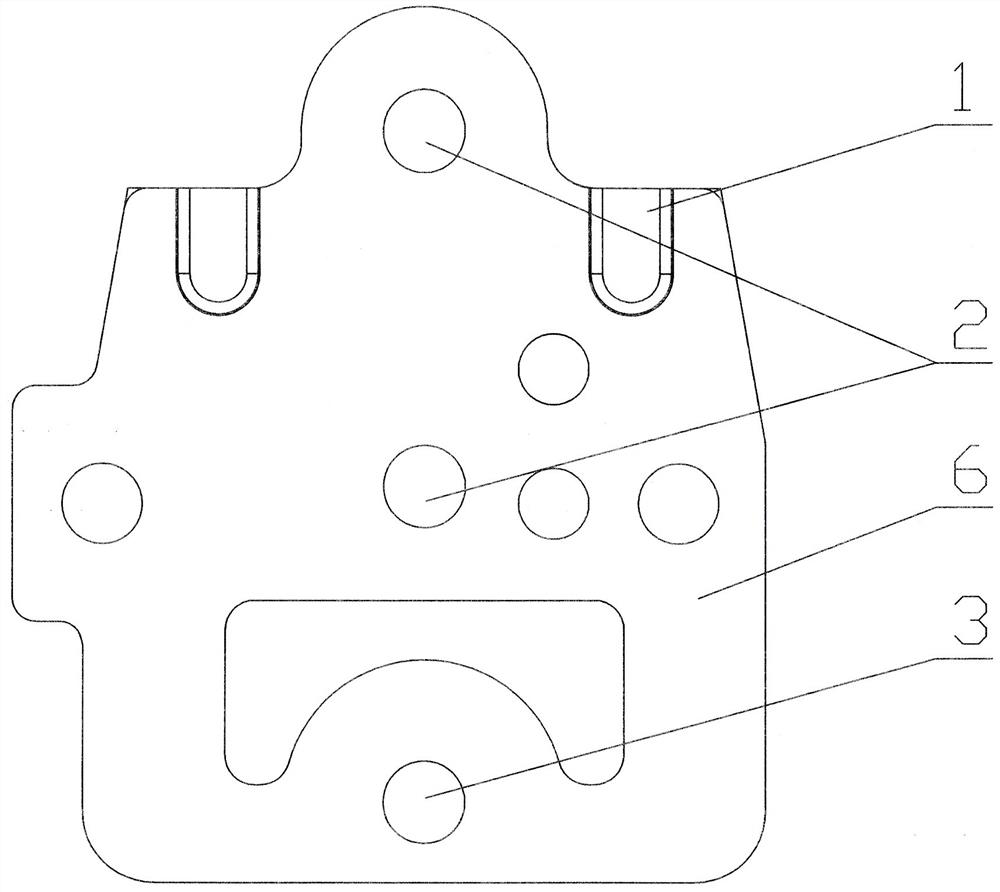

Clamping carrying table for processing of thin wafers and machine tool

ActiveCN108527042AAvoid bending crackingProcess of avoiding debondingGrinding work supportsPlane surface grinding machinesMagnetorheological fluidBreakage rate

The invention discloses a clamping carrying table for processing of thin wafers. The clamping carrying table for processing of thin wafers comprises a trough, wherein the inside of the trough is provided with magnetorheological fluid; an excitation device which is used for driving the magnetorheological fluid to be solidified or to reset to be in a fluid state is arranged on the bottom of the trough; a paper conveying mechanism is arranged on the trough, and periodically supplies single pieces of paper into the trough; the paper floats on the surface of the magnetorheological fluid; and a paper drawing mechanism is arranged on the other side, which is away from the paper conveying mechanism, of the trough. When a wafer to be processed is placed on paper, the paper drawing mechanism draws the paper so that the paper is drawn away from space between the wafer and the surface of the magnetorheological fluid. By the provided clamping carrying table for processing of thin wafers, a functional wafer can be fixed without a carrying wafer, the strength of the functional wafer is high, the breakage rate is low in a processing course, and the yield of final products is high.

Owner:NANTONG XINRUIT MACHINERY CO LTD

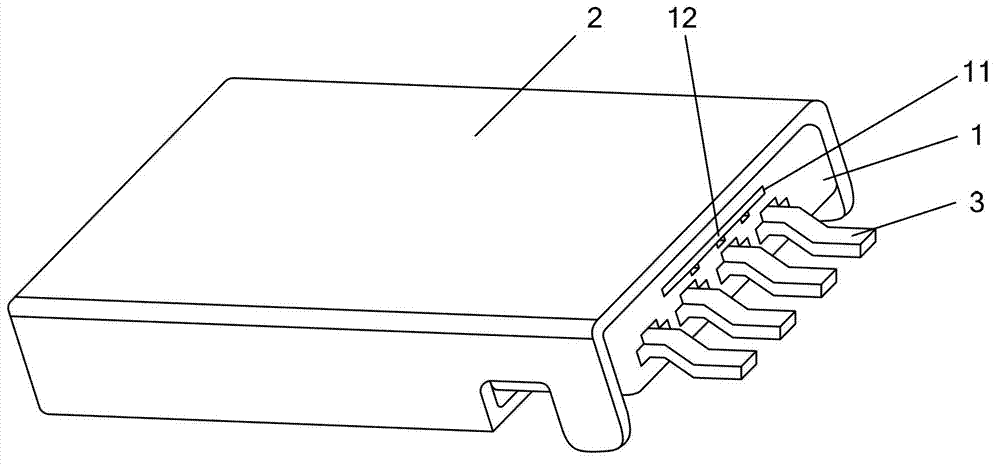

UBS male joint and electronic product having same

InactiveCN103594840AHigh strengthAvoid bending crackingRelieving strain on wire connectionCouplings bases/casesEngineeringUSB

A USB male connector and its companion electronic product are disclosed, which are related to the field of the connector structure, and improve the strength of a USB male connector at a lower cost, and therefore, preventing the USB male connector from bending and cracking. The USB male connector includes: an insulating body, a slot installed in the insulating body, and a reinforcement structure fixed in the slot, where the strength of the reinforcement structure is greater than the strength of the insulating body. The USB male connector has an open end and a tail end that is opposite to the open end. A socket of the slot is located in the tail end of the USB male connector. The electronic product includes an electronic product body and the USB male connector, where the USB male connector is fixedly connected to the electronic product body.

Owner:HUAWEI DEVICE CO LTD

Method for producing hot rolled steel coils

InactiveCN102127699BReduce dosageSimple methodProcess efficiency improvementNiobiumMaterials science

The invention relates to a method for producing hot rolled steel coils. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the Q345R hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

Clamping stages and machine tools for thin wafer processing

ActiveCN108527042BAvoid bending crackingProcess of avoiding debondingGrinding work supportsPlane surface grinding machinesMagnetorheological fluidBreakage rate

The invention discloses a clamping carrying table for processing of thin wafers. The clamping carrying table for processing of thin wafers comprises a trough, wherein the inside of the trough is provided with magnetorheological fluid; an excitation device which is used for driving the magnetorheological fluid to be solidified or to reset to be in a fluid state is arranged on the bottom of the trough; a paper conveying mechanism is arranged on the trough, and periodically supplies single pieces of paper into the trough; the paper floats on the surface of the magnetorheological fluid; and a paper drawing mechanism is arranged on the other side, which is away from the paper conveying mechanism, of the trough. When a wafer to be processed is placed on paper, the paper drawing mechanism draws the paper so that the paper is drawn away from space between the wafer and the surface of the magnetorheological fluid. By the provided clamping carrying table for processing of thin wafers, a functional wafer can be fixed without a carrying wafer, the strength of the functional wafer is high, the breakage rate is low in a processing course, and the yield of final products is high.

Owner:NANTONG XINRUIT MACHINERY CO LTD

A kind of aluminum-plastic panel production process

ActiveCN110281635BIncrease pit heat pit combustion performanceQuality improvementLamination ancillary operationsLaminationSurface finishFire retardant

The invention discloses a production process of an aluminum-plastic plate. The process comprises mixing and stirring, extrusion molding, degreasing treatment, formation treatment, coating treatment, compounding treatment and trimming treatment. A non-halogen flame retardant and a defoaming agent are added in the preparation process of a plastic core plate; the heat and burning resistant properties of an aluminum-plastic plate part can be greatly increased by the non-halogen flame retardant; the surface smooth finish of the prepared plastic core plate can be higher by adding the defoaming agent; the plastic core plate is prevented from generating bubbles in the preparation process; the quality of the produced aluminum-plastic plate part is effectively improved; blank extruded through an extruder barrel flows into a wedge-shaped material guiding cavity, and falls into a preforming compressing device through a strip-shaped outlet of the wedge-shaped material guiding cavity; the preformed compressing device extrudes the inner blank into a plate-like structure by a water-cooling pressing roller I and a water-cooling pressing roller II; then the preliminarily molded plastic core plate is introduced into a subsequent water-cooling pressing roller to perform the extrusion shaping to obtain the plastic core plate; the phenomena of bending cracking and the like which easily appear in the one-step shaping process of the plastic core plate are avoided.

Owner:安徽英标新材料科技有限公司

Method for producing hot rolled steel coil

The invention relates to a method for producing a hot rolled steel coil. The method comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching between nitrogen and argon, and performing tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, controlling tundish molten steel amount to be between 8t and 15t and liquid level to be between 200mm and 350mm when a continuous casting tundish stops pouring, and pouring under protection in the entire process, wherein the length of an inserted part of a long nozzle is between 300mm and 400mm; 3) heating the plate blank; and 4) finally rolling the heated plate blank and winding to obtain the hot rolled steel coil. In the method, a thermomechanical control process (TMCP) and a relaxation-precipitation-control (RPC) rolling process are adopted, and C content and Mn content are greatly reduced by micro niobium treatment, so that production cost is reduced; the Q345q-E hot rolled steel coil produced by the method has high plasticity and toughness, and the elongation rate of the hot rolled steel coil is improved by more than 8 percent; meanwhile, the welding properties of materials are improved, and high surface quality of a continuous casting blank is guaranteed.

Owner:NINGBO IRON & STEEL

Method for producing hot rolled steel coils for ship building

InactiveCN102127694AReduce dosageSimple methodProcess efficiency improvementMarine engineeringStructural engineering

The invention relates to a method for producing hot rolled steel coils for ship building. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the grade A32 hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

Method for producing hot-rolled steel coil for shipbuilding

The invention relates to a method for producing a hot-rolled steel coil for shipbuilding, which comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching nitrogen and argon, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein the content of the molten steel in a continuously cast intermediate ladle is controlled to be between 8 and 15t and the liquid level is controlled to be between 200 and 350mm when the intermediate ladle is not poured; and pouring is protectedin the whole process, and the insertion depth of a long nozzle is between 300 and 400mm; 3) heating the plate blank; and 4) rolling and curling the heated plate blank. The content of C and Mn is greatly reduced through niobium microalloying by a thermo-mechanical controlled process-relaxed precipitation control (TMCP-RPC) rolling process, and production cost is reduced; the obtained grade D36 hot-rolled steel coil for shipbuilding has high plasticity and toughness, and the elongation of the hot-rolled steel coil is improved by over 8 percent; meanwhile, the welding performance of the materialis improved, and the high surface quality of a continuously cast blank is ensured.

Owner:NINGBO IRON & STEEL

Production method of hot rolled steel coil for shipbuilding

The invention relates to a production method of hot rolled steel coil for shipbuilding. The method comprises the following steps of: (1) designing contents, preprocessing molten iron, then, smelting in a converter, switching nitrogen and argon and tapping to obtain molten iron; (2) continuously casting the molten iron to obtain a plate blank, controlling the molten iron amount to be 8-15t and theliquid level to be 200-350 mm when stopping casting a continuous casting tundish and wholly protecting and casting while the insertion depth of a long water opening is 300-400 mm; (3) heating the plate blank; and (4) finally, rolling and coiling the heated plate blank. The invention adopts a RPC (Relaxation-Precipitation-phase Control) and TMCP (Thermomechnical Control Process) rolling process, decreases the C and Mn contents by utilizing niobium microalloying treatment and decreases production cost. The D32-level hot rolled steel coil for shipbuilding has excellent plasticity and toughness, the extensibility is improved by over 8 percent, the welding performance of the material is improved and the favorable surface quality of a continuous casting blank is ensured.

Owner:NINGBO IRON & STEEL

Method for producing hot rolled steel coils

Owner:NINGBO IRON & STEEL

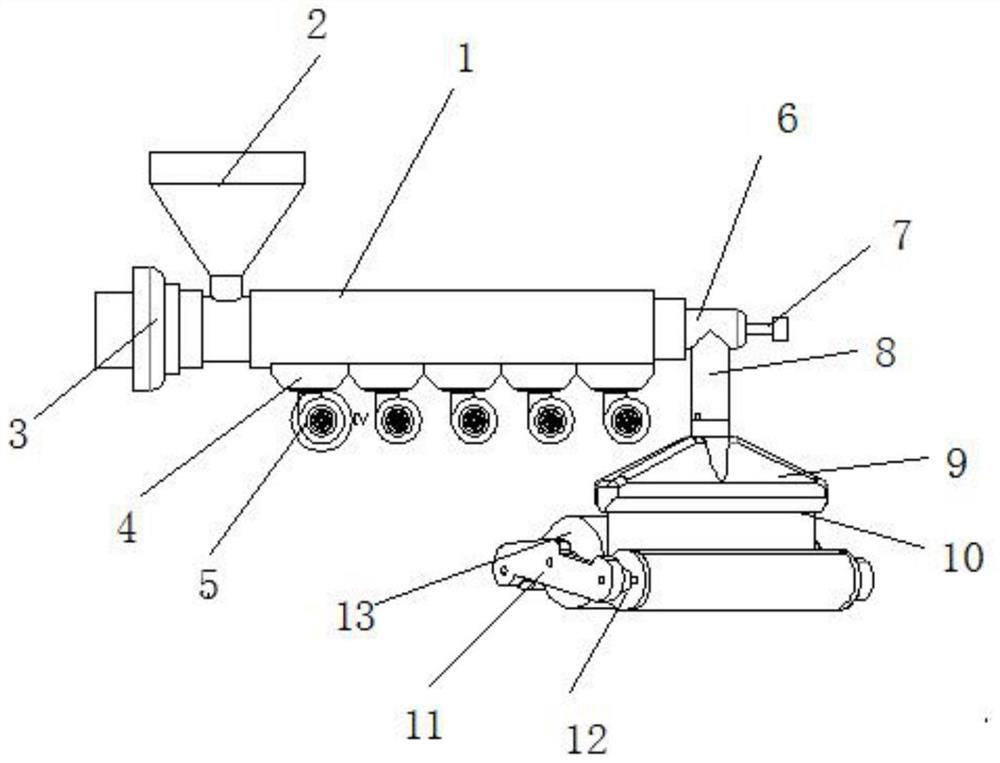

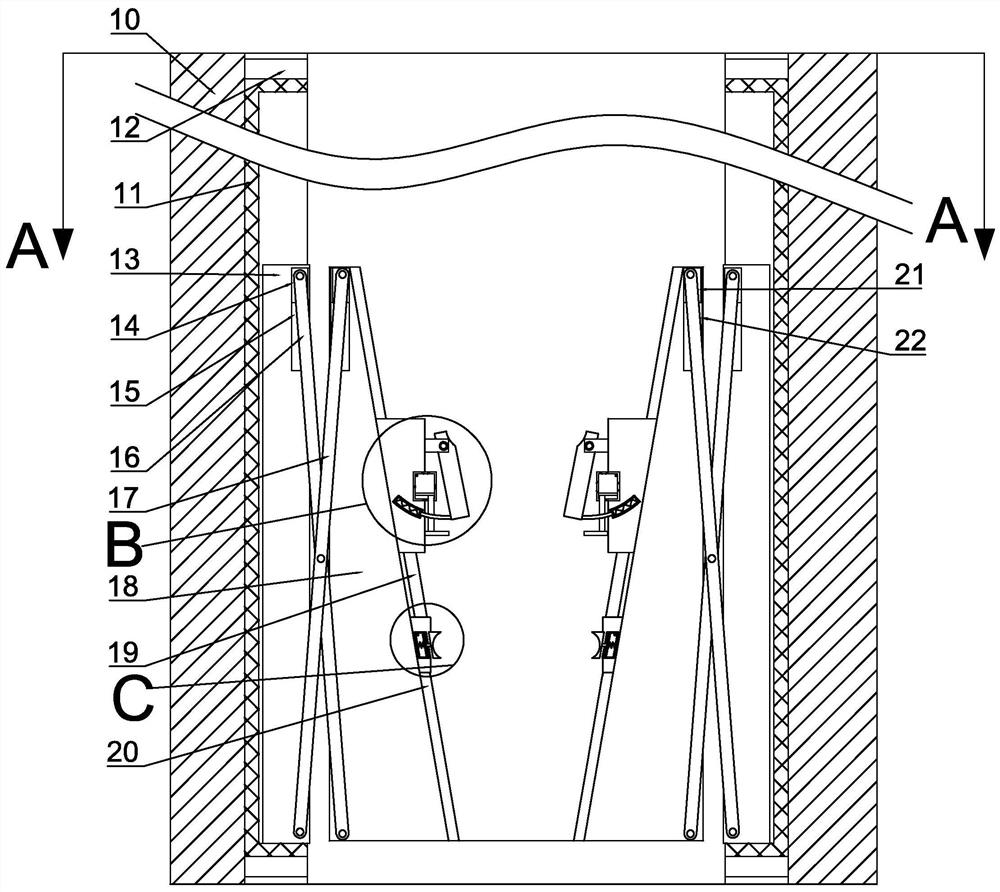

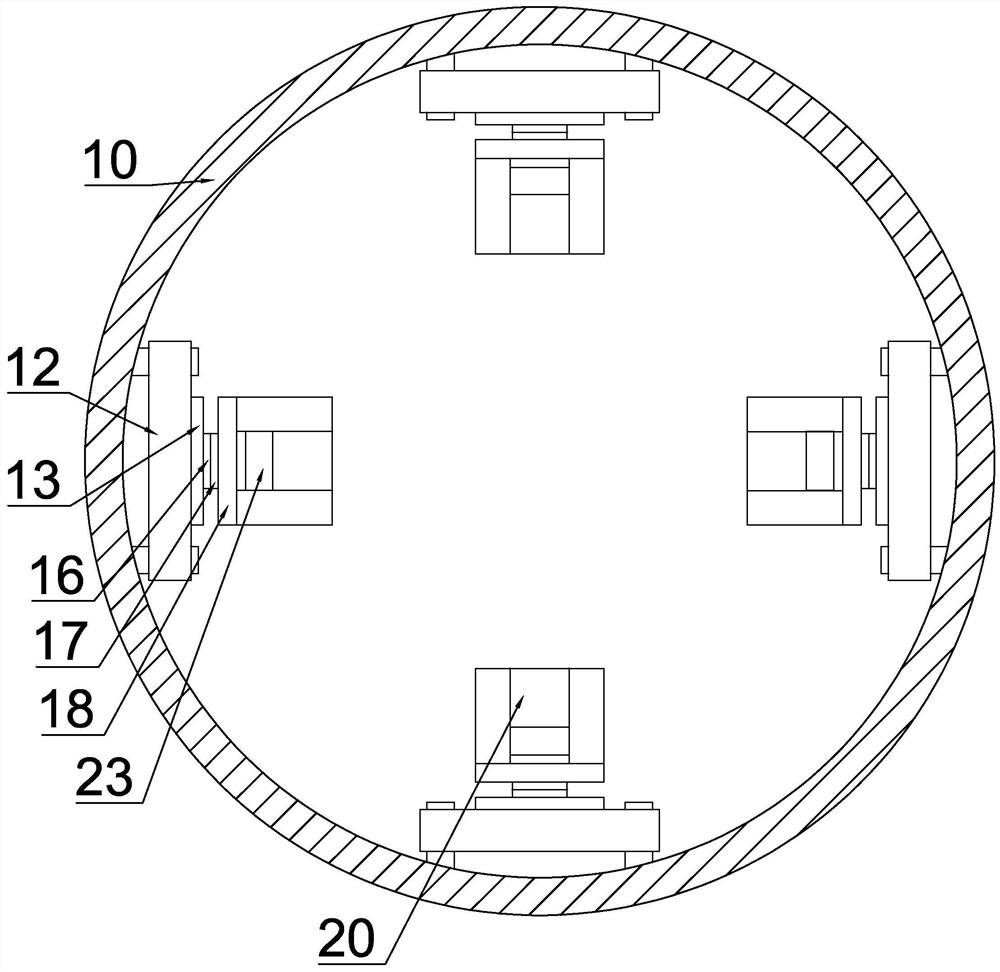

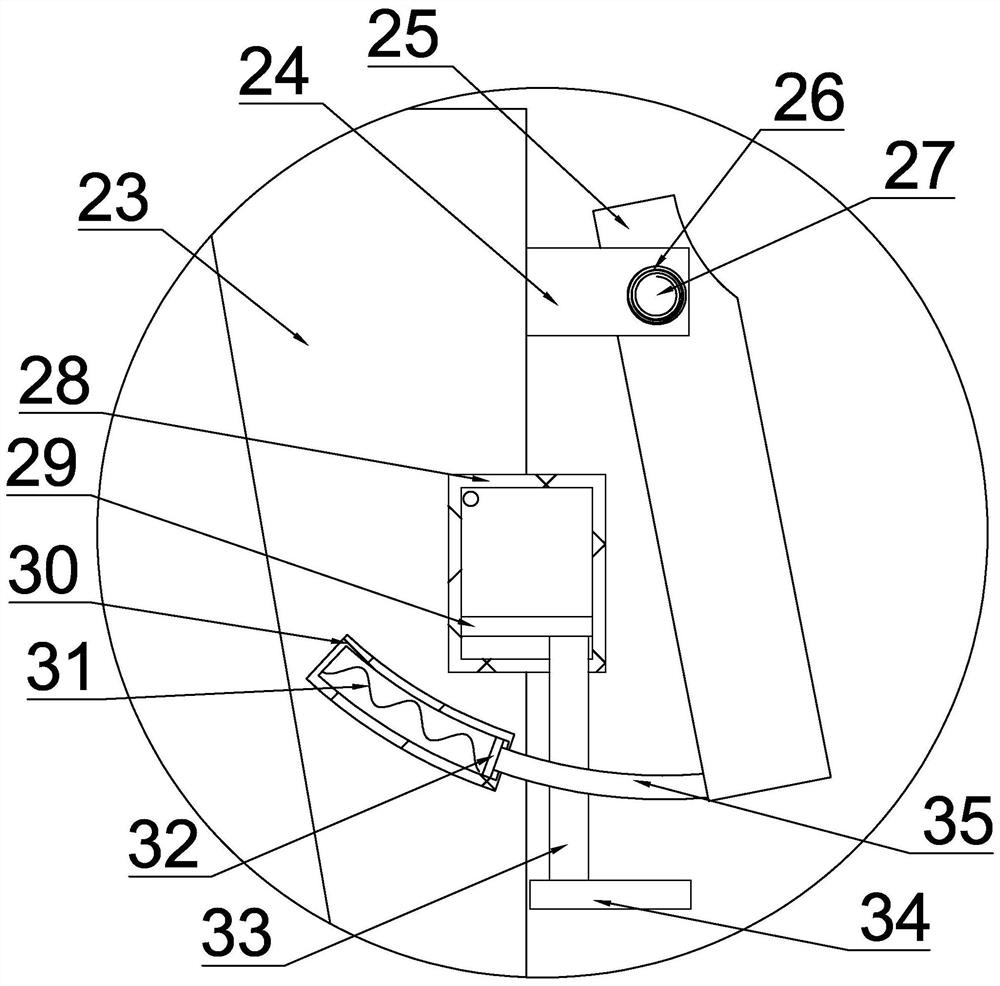

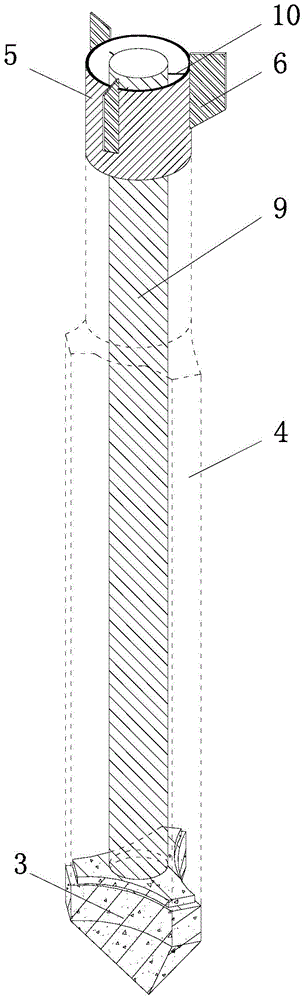

Pile foundation pouring system for building

InactiveCN113373932AGuaranteed coaxialEasy to place and operateBulkheads/pilesArchitectural engineeringSlide plate

The invention belongs to the related field of pile foundations, and relates to a pile foundation pouring system for a building. The system comprises a steel casing wall, four detachable bolt holes capable of being connected through bolts and nuts are formed in the inner wall of the steel casing wall, a lifting groove is fixedly formed in each bolt hole, and a lifting sliding plate is arranged in each lifting groove in an up-down sliding manner. A size adapting device is arranged on each lifting sliding plate. The system is detachably mounted on a steel casing, is placed into a drill hole together with the steel casing, and is used for assisting in placing of a reinforcement cage, ensuring that the reinforcement cage and a steel casing are coaxial, protecting the reinforcement cage from floating due to buoyancy in the concrete injection process, and hooping the lower layer of the reinforcement cage by utilizing the floating buoyancy, therefore, the structure of the reinforcement cage is prevented from being damaged by pressure, the working efficiency during pile foundation drilling is improved, the reinforcement cage is protected, and the stability of a pile foundation is improved.

Owner:刘凤华

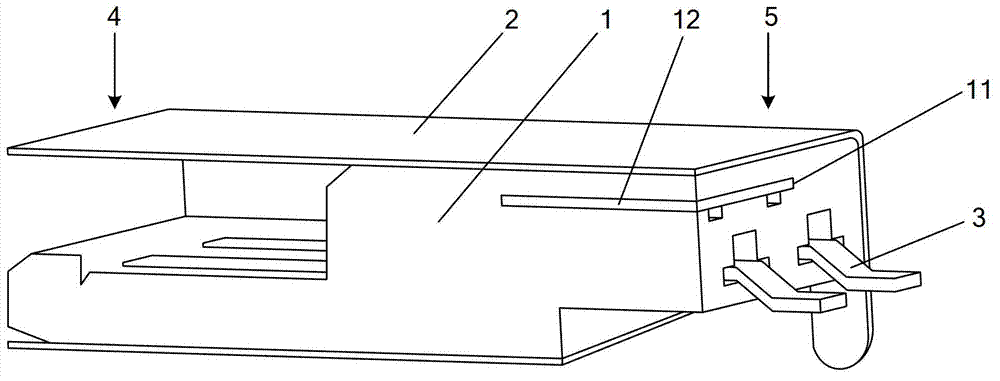

Auxiliary device and pressure maintaining system

ActiveCN108254948BAvoid bending crackingNon-linear opticsInput/output processes for data processingColor gelElectrical connection

Owner:INTERFACE TECH CHENGDU CO LTD +2

Method for producing hot-rolled steel coil for shipbuilding

The invention relates to a method for producing a hot-rolled steel coil for shipbuilding, which comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching nitrogen and argon, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein the content of the molten steel in a continuously cast intermediate ladle is controlled to be between 8 and 15t and the liquid level is controlled to be between 200 and 350mm when the intermediate ladle is not poured; and pouring is protected in the whole process, and the insertion depth of a long nozzle is between 300 and 400mm; 3) heating the plate blank; and 4) rolling and curling the heated plate blank. The content of C and Mn is greatly reduced through niobium microalloying by a thermo-mechanical controlled process-relaxed precipitation control (TMCP-RPC) rolling process, and production cost is reduced; the obtained grade D36 hot-rolled steel coil for shipbuilding has high plasticity and toughness, and the elongation of the hot-rolled steel coil is improved by over 8 percent; meanwhile, the welding performance of the material is improved, and the high surface quality of a continuously cast blank is ensured.

Owner:NINGBO IRON & STEEL

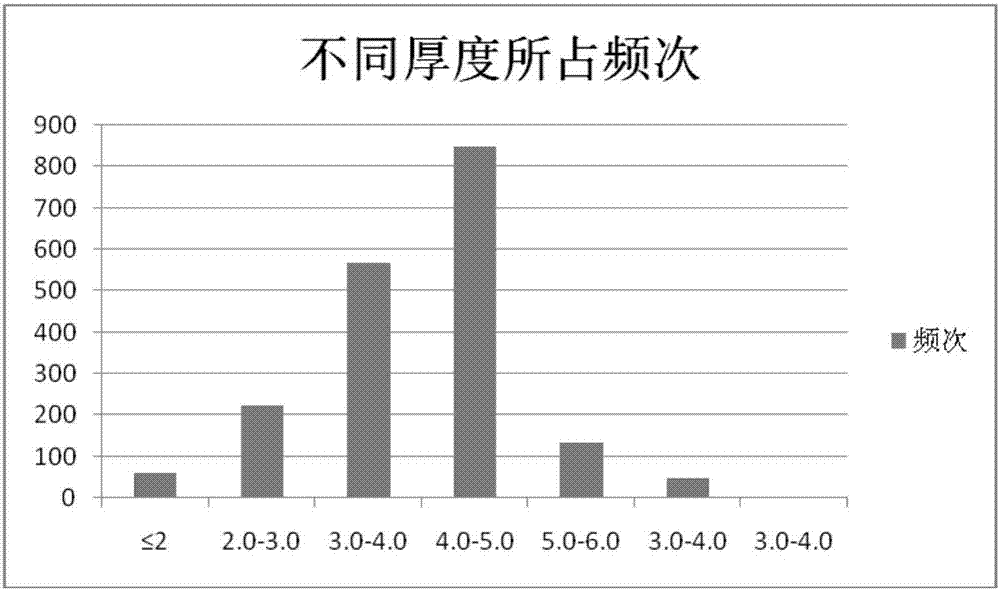

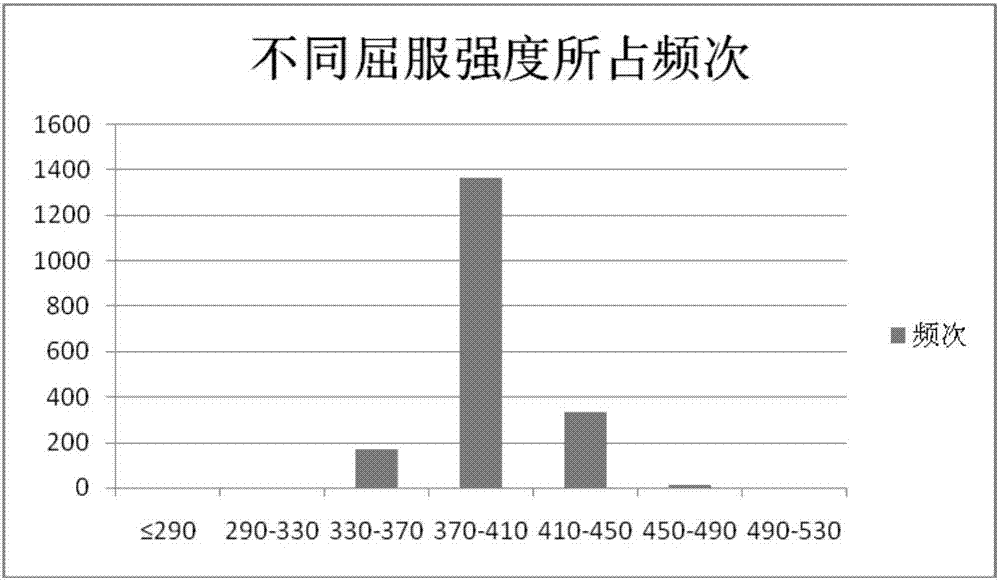

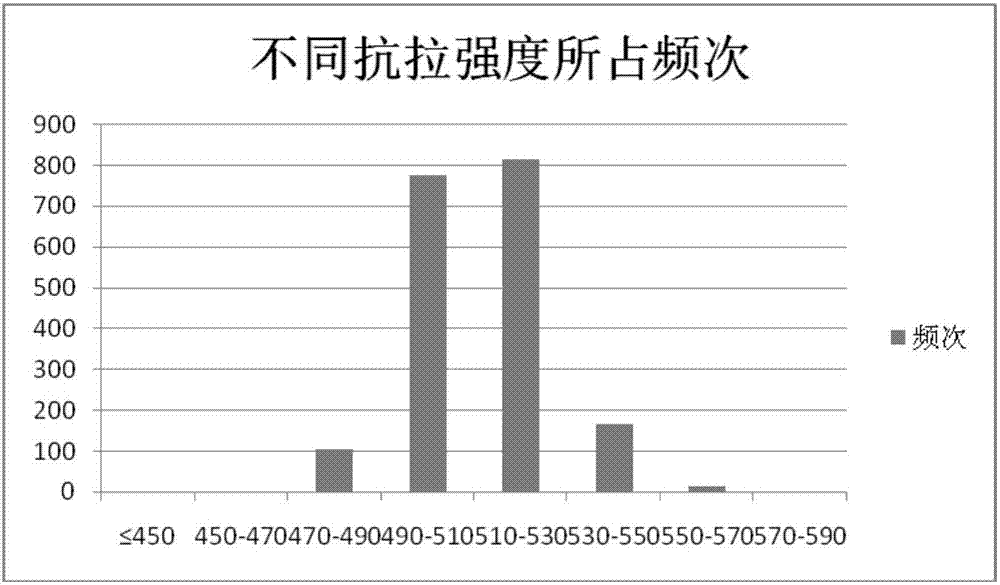

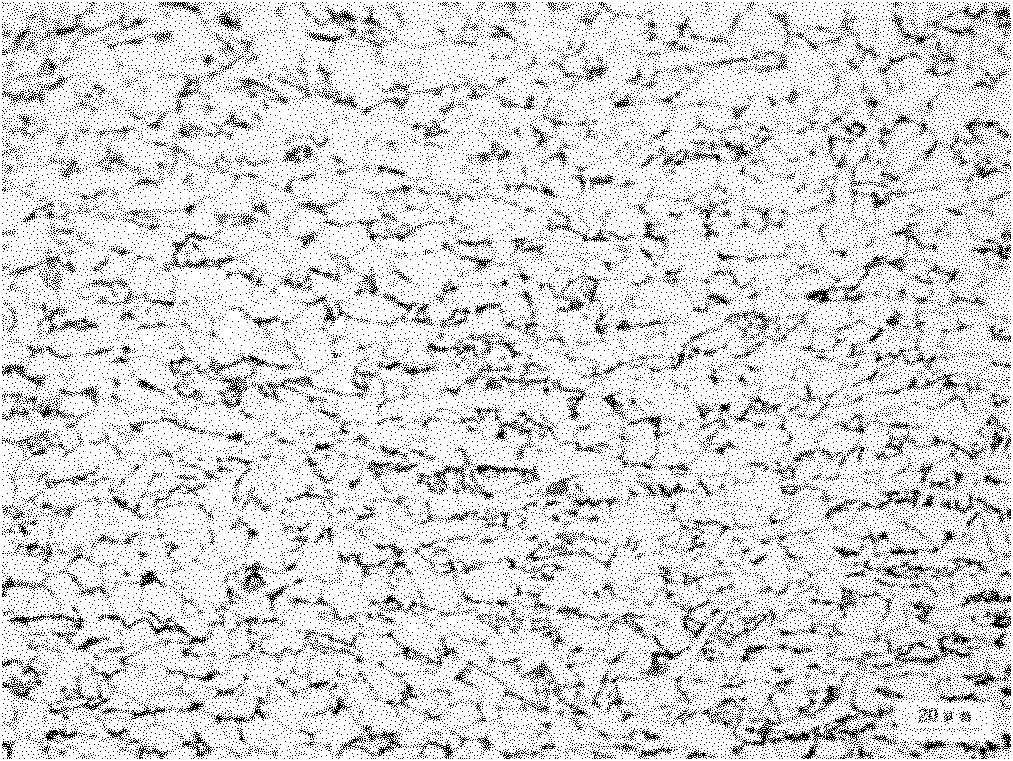

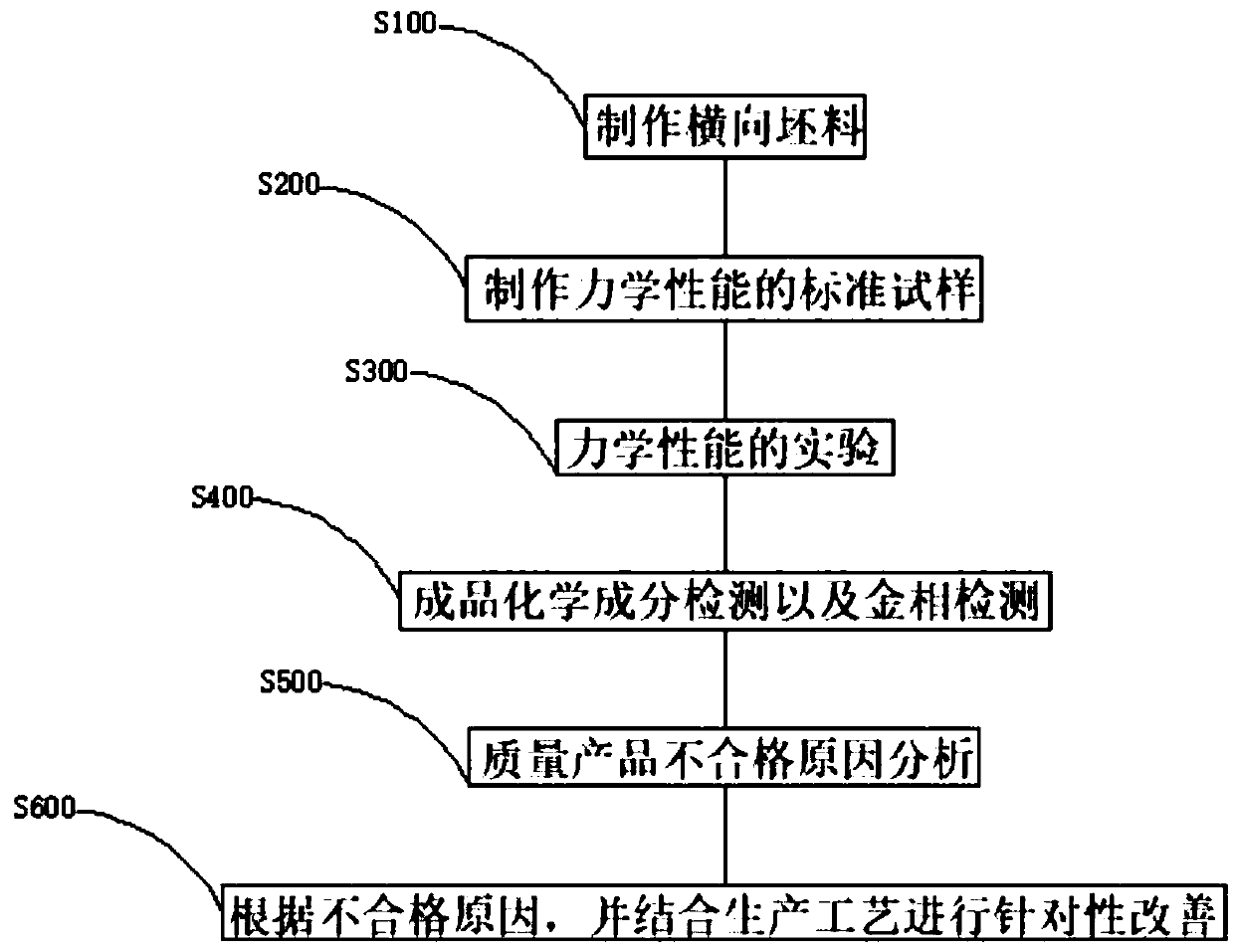

Quality evaluation method for preventing hot-rolled plain carbon steel from cracking during 90-degree bending

PendingCN110806472AAvoid bending crackingGood reputationPreparing sample for investigationTesting metalsChemical compositionCarbon steel

The invention discloses quality monitoring and provides a quality evaluation method for preventing hot-rolled plain carbon steel from cracking during 90-degree bending, which comprises the following steps: step S100: manufacturing a transverse blank; step S200: manufacturing a standard sample of a mechanical property; step S300: testing the mechanical property; step S400: performing chemical component detection and metallographic detection on a finished product; step S500: analyzing an unqualified reason of a quality product; and step S600: performing targeted improvement according to the unqualified reason in combination with a production process. The quality evaluation method of the invention has the beneficial effects that: it is ensured that a delivery product is not cracked when beingbent on the position of a user, quality objections are avoided, good reputation is gained from the user, and a large market share is obtained; the quality of iron and steel production enterprises ispromoted to be comprehensively improved, the reason and the working procedure causing the unqualified quality are determined through metallographic microscopic analysis, the improvement can be purposefully realized, and the quality is promoted comprehensively.

Owner:山西建龙实业有限公司

A construction method of special-shaped piles with carbon fiber bag cast-in-place anti-arch curved surface combination

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

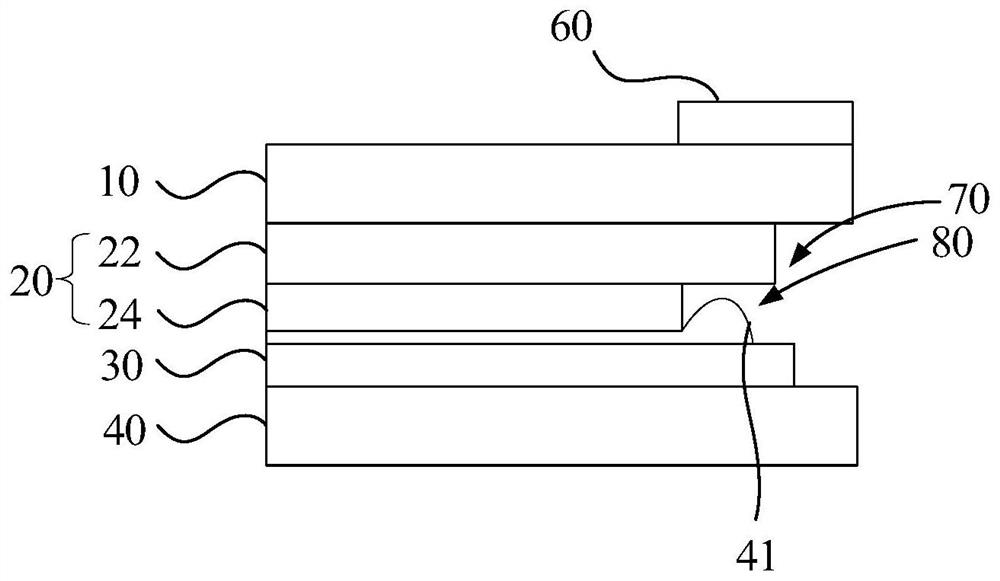

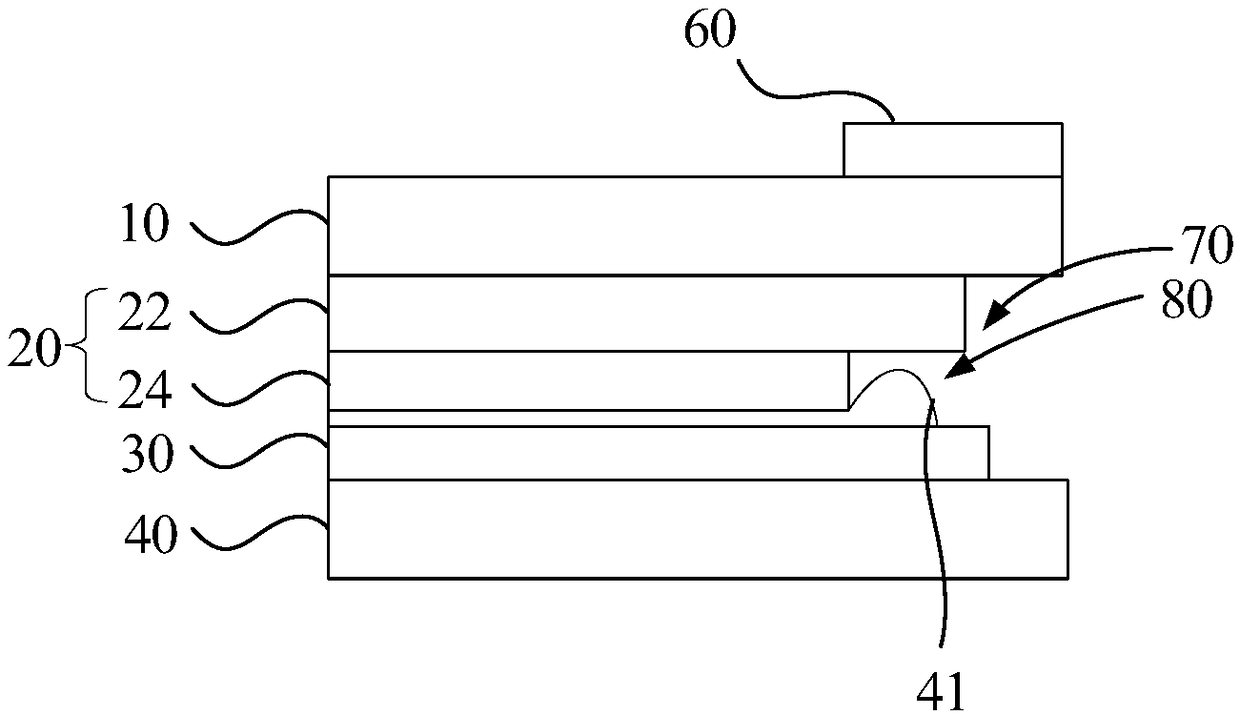

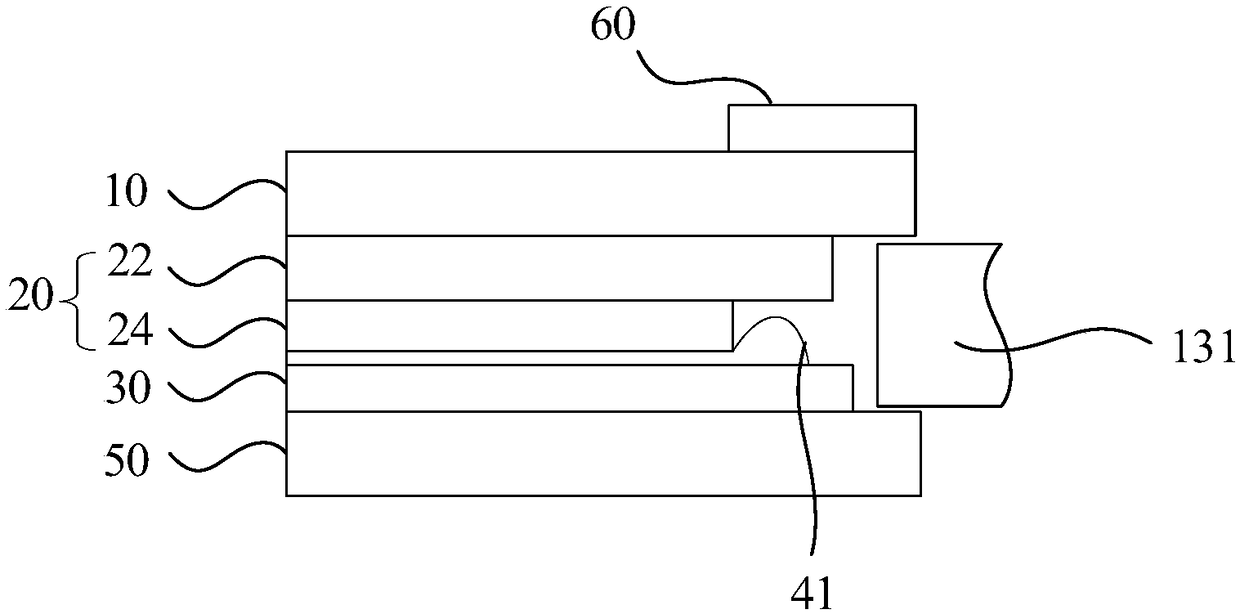

Auxiliary device and pressure holding system

ActiveCN108254948AAvoid bending crackingNon-linear opticsInput/output processes for data processingElectricityColor gel

The invention relates to an auxiliary device and a pressure holding system. The auxiliary device is used for cooperating with the pressure holding device to conduct a pressure holding product processon a touch control display panel, wherein the touch control display panel comprises a backlight sheet, a thin film transistor substrate, a color filter substrate, a touch control module and a protective cover plate which are stacked in turn, a gap is formed at an edge between the backlight sheet and the protective cover plate, an electrical connection element is arranged at an edge, away from thesurface of the protective cover plate, of the backlight sheet, in the pressure holding product process, the pressure holding device is pressed against the electrical connection element, the auxiliarydevice comprises a gasket, and the gasket can extend into the gap to support the backlight sheet to be close to the surface of the protective cover plate when the pressure holding device is pressed against the electrical connection element, so that it is avoided that the thin film transistor substrate is bent and broken toward the protective cover plate.

Owner:INTERFACE TECH CHENGDU CO LTD +2

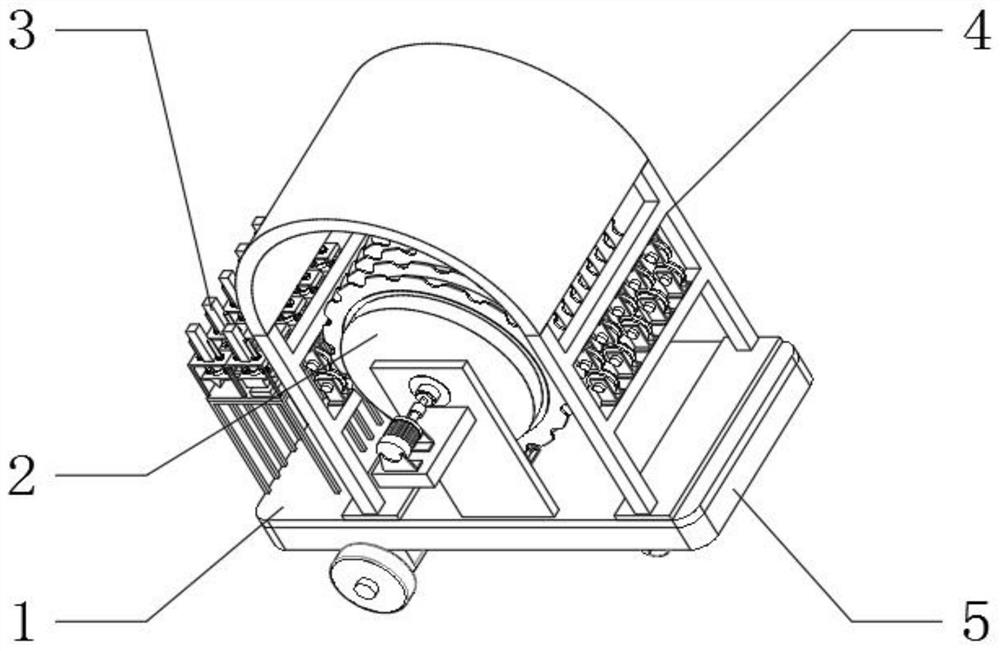

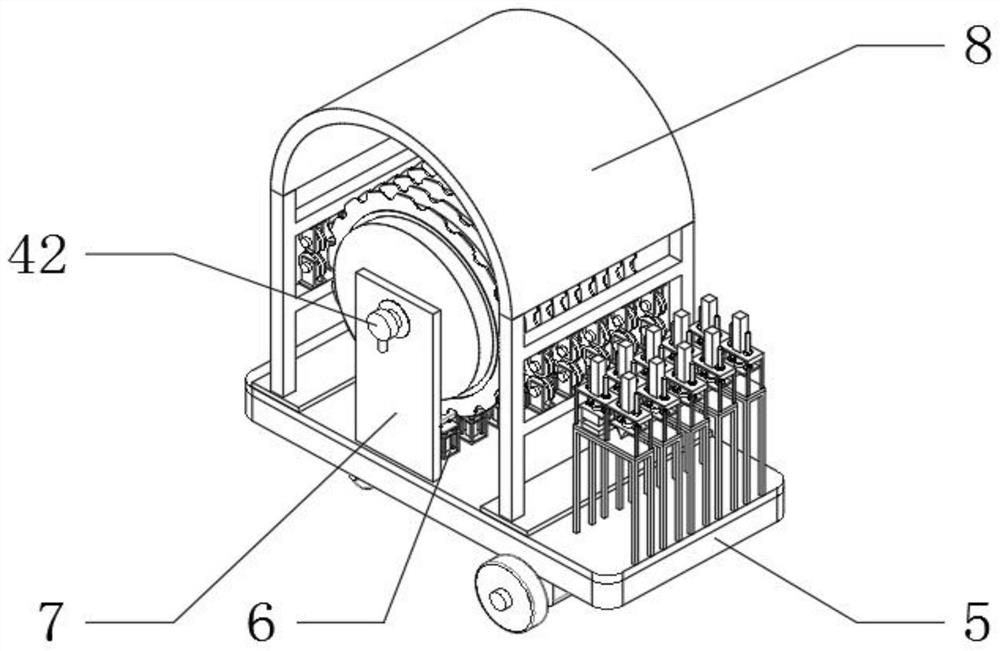

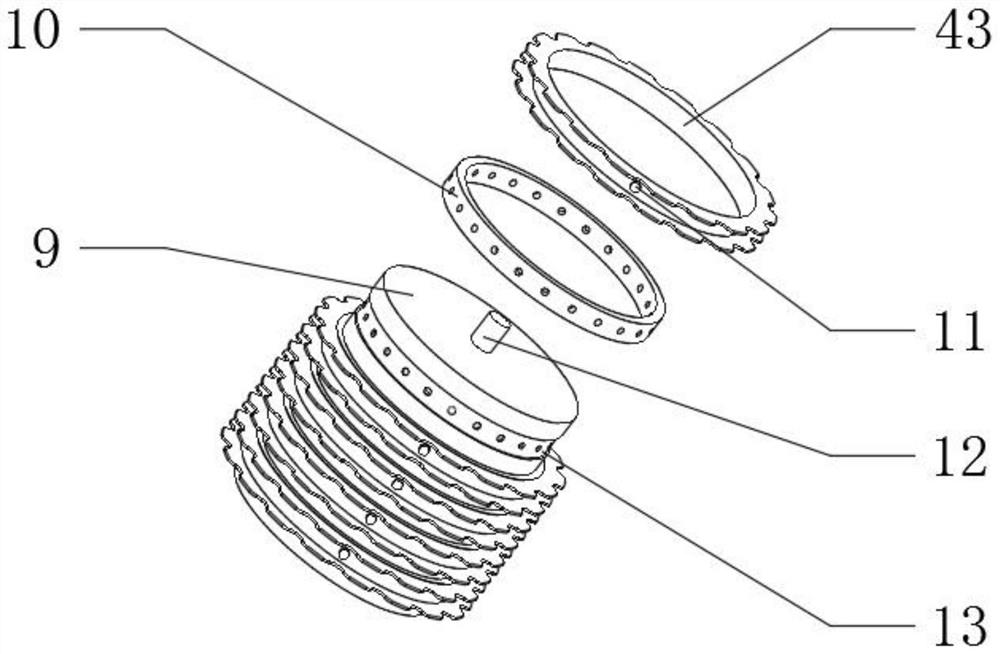

Placing frame convenient to take for cable machining

The invention discloses a placing rack convenient to take for cable machining and relates to the technical field of cable machining equipment. The placing frame aims at solving the problem about taking two functions of automatic feeding and manual material taking into consideration. The placing frame specifically comprises a bottom plate. The outer wall of the top of the bottom plate is fixedly connected with a support, and the inner wall of the support is rotationally connected with a storage assembly through a bearing. The outer wall of the top of the bottom plate is fixedly connected with adischarging assembly, a splitting assembly and a clamping assembly. The storage assembly comprises a main cylinder and two trunnions which are rotationally connected to the inner walls of the two ends of the main cylinder. Sliding grooves are formed in the outer wall of the main cylinder, and lantern rings are rotationally connected to the inner walls of the sliding grooves. According to the placing frame convenient to take for cable machining, through the arrangement of the storage assembly, when a first air cylinder contracts, a connecting rod is disengaged from the inner wall of a pin hole, the lantern rings are in a movable state relative to the main cylinder, automatic rotation can be achieved through manpower, field workers can conveniently draw and pull cables according to the needed length, meanwhile, the number of wire boxes and the number of the lantern rings are both five, and storage of various cables of different specifications can be met.

Owner:湖南新耒传导材料科技有限公司

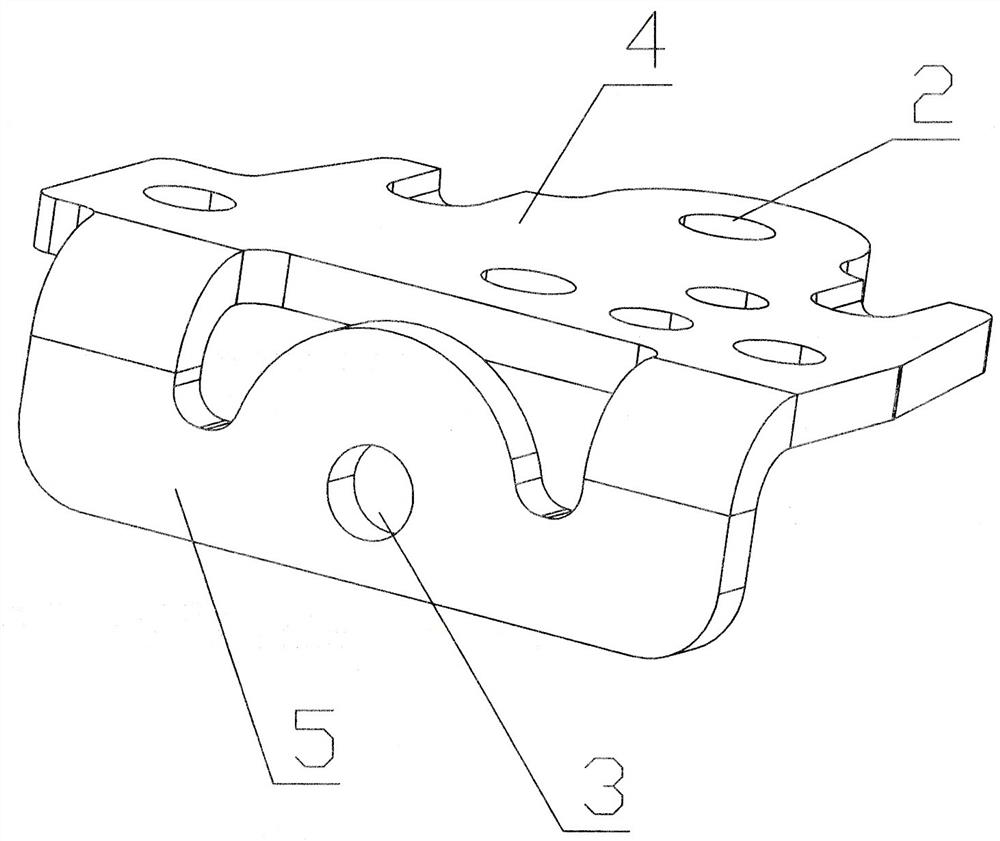

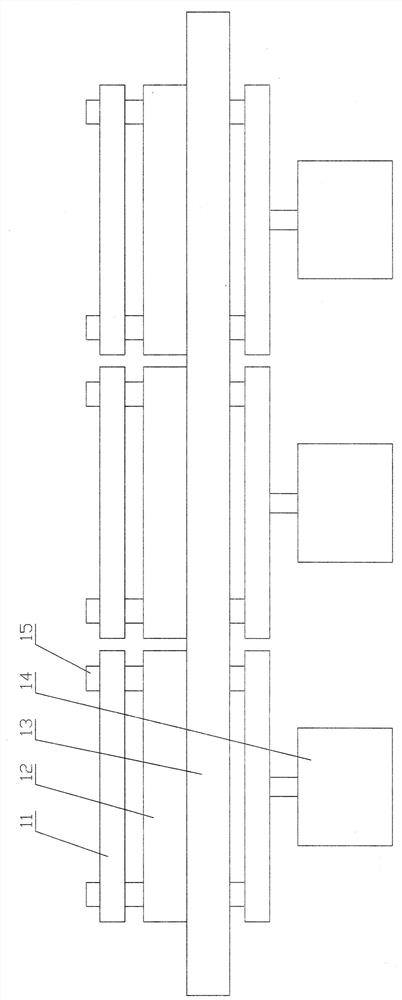

A production method of positioning connection bracket

The invention discloses a method for producing a positioning and connecting bracket, which is characterized by comprising the following steps: 1) the bracket body is formed by continuous fine blanking and burrs are removed; 2) the bracket body is bent so that the side surface with the connecting rod mounting hole and the The bottom surface with bearing mounting holes and bosses is set vertically; 3) Three mounting holes are machined with a CNC milling machine, and ultrasonic cleaning is used. The invention adopts reasonable and efficient processing procedures, and combines the processing of high-precision machine tools, high-precision fixtures and high-precision tools to realize high-precision positioning and connecting brackets, solves the processing problems in the prior art, and has breakthrough significance.

Owner:ZHONGJING GROUP

Method for producing hot-rolled steel coil

The invention relates to a method for producing a hot-rolled steel coil, which comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching nitrogen and argon, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein the content of the molten steel in a continuously cast intermediate ladle is controlled to be between 8 and 15t and the liquid level is controlled to be between 200 and 350mm when the intermediate ladle is not poured; and pouring is protected in the whole process, and the insertion depth of a long nozzle is between 300 and 400mm; 3) heating the plate blank; and 4) rolling and curling the heated plate blank. The content of C and Mn is greatly reduced through niobium microalloying by a thermo-mechanical controlled process-relaxed precipitation control (TMCP-RPC) rolling process, and production cost is reduced; the obtained Q345q-D hot-rolled steel coil has high plasticity and toughness, and the elongation of the hot-rolled steel coil is improved by over 8 percent; meanwhile, the welding performance of the material is improved, and the high surface quality of a continuously cast blank is ensured.

Owner:NINGBO IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com