Placing frame convenient to take for cable machining

A technology for placing racks and cables, applied in the field of placing racks for cable processing, can solve the problems of a large amount of cable discharge, the inability to take out manual removal, and the inability of workers to recover in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

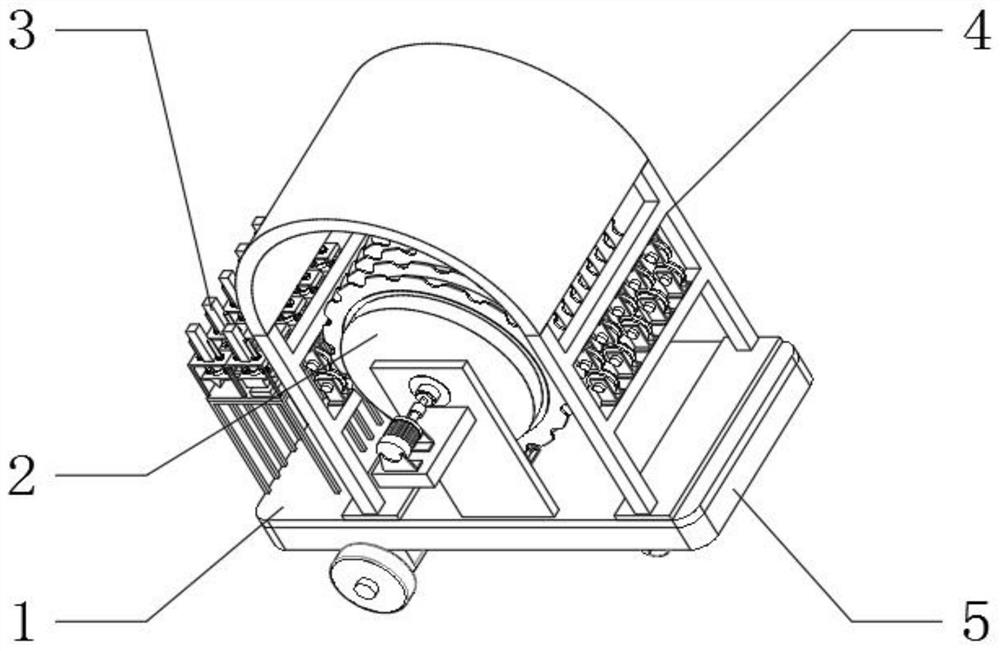

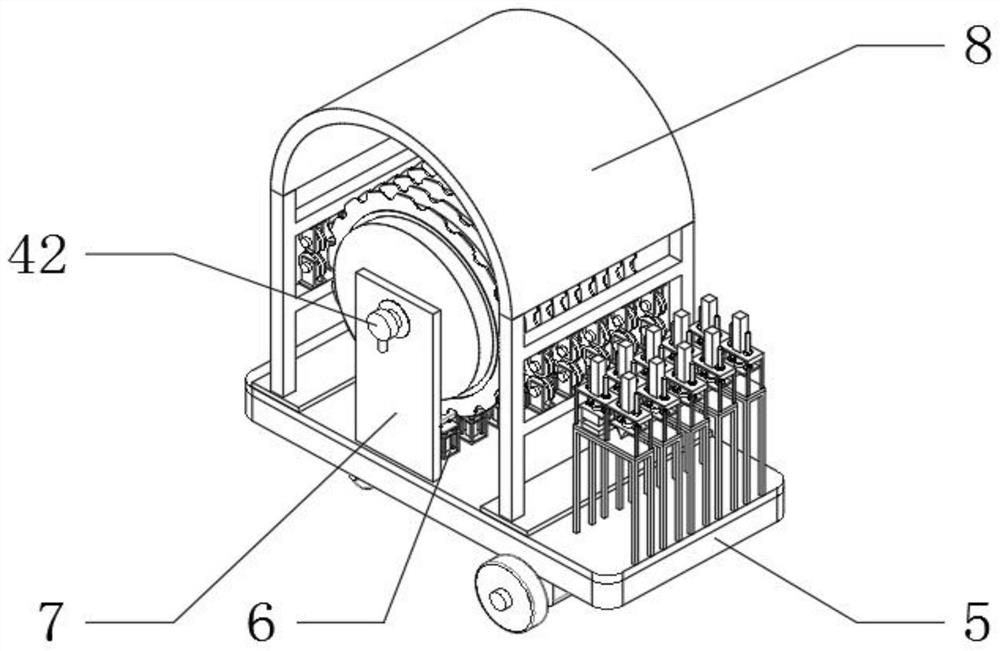

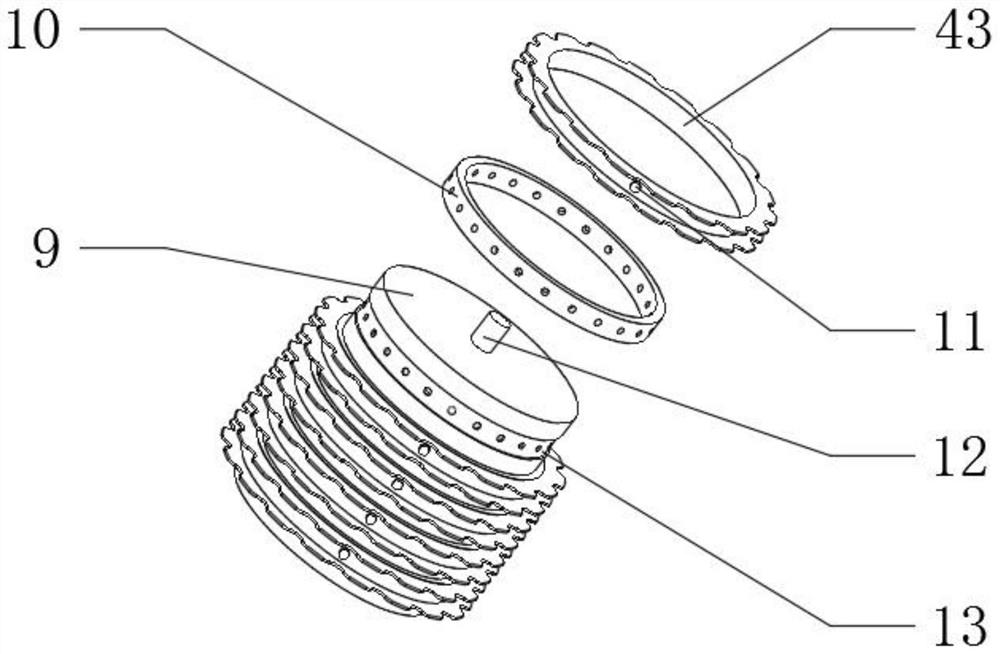

[0036] An easy-to-take display rack for cable processing, such as Figure 1-8As shown, it includes a bottom plate 1, the top outer wall of the bottom plate 1 is fixedly connected with a bracket 7, the inner wall of the bracket 7 is connected with a storage assembly 2 through bearing rotation, and the top outer wall of the bottom plate 1 is fixedly connected with a discharge assembly 3, a sorting assembly 4 and a stuck Assembly 6; the storage assembly 2 includes a main cylinder 9 and a trunnion 12, the number of the trunnions 12 is two, the trunnion 12 is rotatably connected to the inner wall at both ends of the main cylinder 9, and the outer wall of the main cylinder 9 is provided with a chute 13, and the sliding The inner wall of the slot 13 is rotatably connected with a collar 10, the inner wall of the collar 10 and the chute 13 are provided with pin holes, the outer wall of the collar 10 is fixedly connected with the cable box 43, the outer walls of both sides of the box 43 ...

Embodiment 2

[0043] An easy-to-take display rack for cable processing, such as figure 1 , 7 As shown, for the operation of the main shaft 14; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of one side of the bracket 7 is welded with a mounting plate 31, and the outer wall of the top of the mounting plate 31 is fixedly connected with a bracket. The middle inner wall is rotatably connected with a rotary shaft through a bearing, the outer wall at one end of the rotary shaft is fixedly connected with a handwheel, and the outer wall at the other end of the rotary shaft is connected to the outer wall at one end of the trunnion 12 through a coupling.

[0044] In this embodiment, when the device is started and needs to be moved, the drive box 5 receives an external remote control instruction, and the control device moves to a designated position. When the cable enters the device, the personnel will send the cable through the arrangement assembly 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com