Production process of aluminum-plastic plate

A production process and technology for aluminum-plastic panels, applied in the field of aluminum-plastic panel production, can solve the problems of low production efficiency, increase labor intensity, and low tensile strength, and achieve the effects of improving production efficiency, reducing labor intensity, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

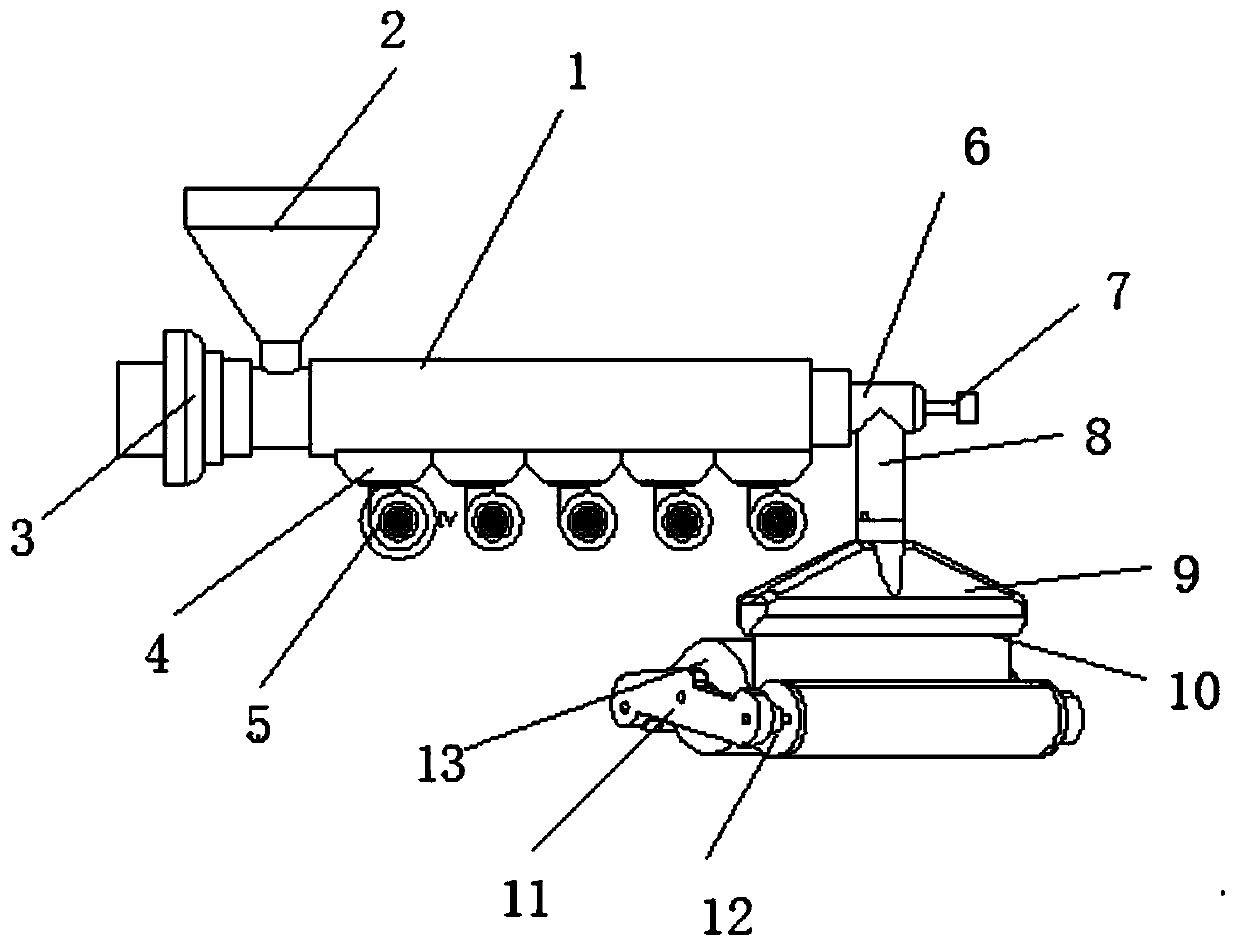

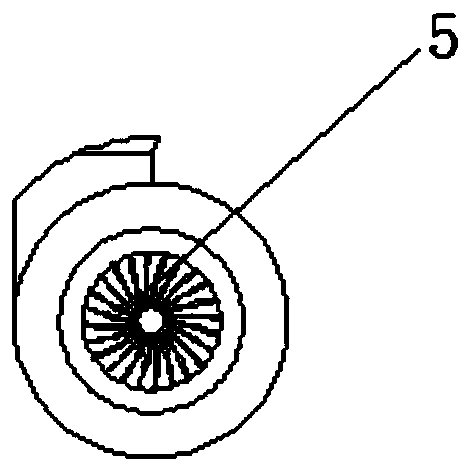

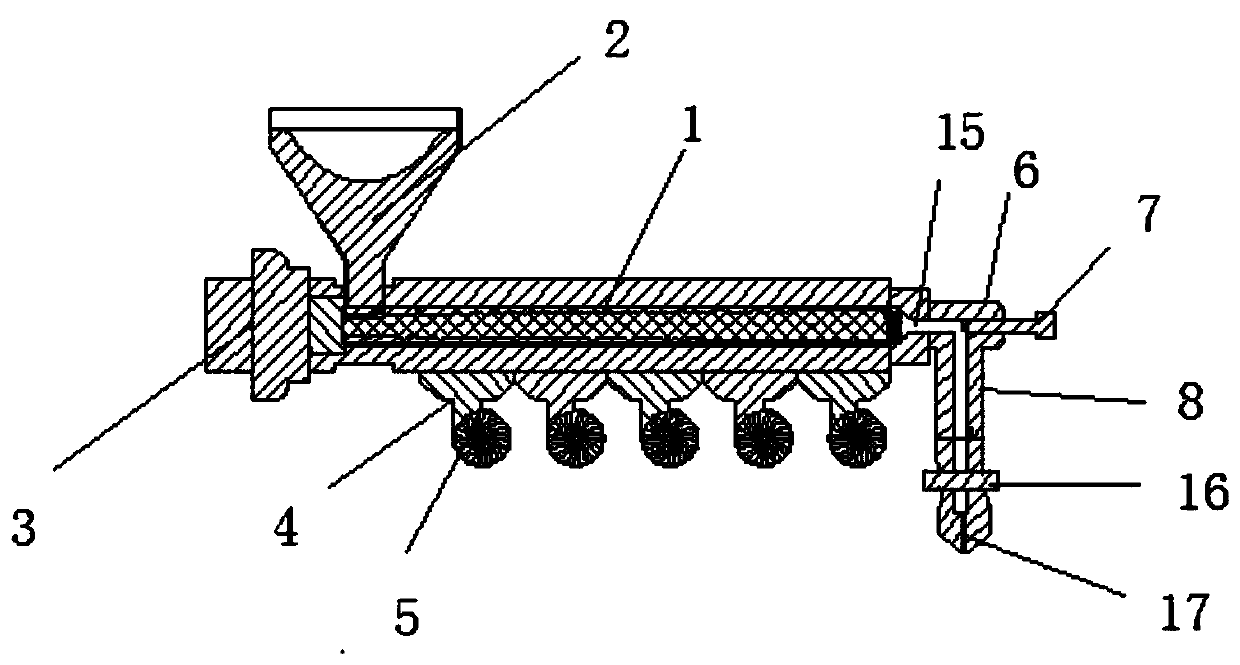

[0041] Such as Figure 1-5 As shown, a production process of an aluminum-plastic panel, the production process of the aluminum-plastic panel specifically includes the following steps:

[0042] Mixing and stirring: put 100 parts by weight of polyethylene in a stirring tank in advance and stir for 3-5 minutes at 100-120r / min, then pour in 3 parts by weight of talcum powder, 2 parts by weight of calcium carbonate, 15 parts by weight of The barium sulfate, the non-halogen flame retardant of 1 weight part and the defoamer of 1 weight part are in the stirred tank with 400-450r / min Stirring 30-45 minutes obtains the plastic mixture, the plastic mixture is sucked by vacuum The machine is sucked into the hopper of the extruder;

[0043] Extrusion blank: the plastic mixture is sucked into the extruder barrel 1 through the feed port 2, the motor drive device 3 is started, and the motor drive device 3 drives the extrusion screw in the extruder barrel 1 to rotate, and the extruder barrel ...

Embodiment 2

[0050] The specific steps of the production process of the aluminum-plastic panel are as follows:

[0051] Mixing and stirring: put 100 parts by weight of polyethylene in a stirring tank in advance and stir at 100-120r / min for 3-5 minutes, then pour in 8 parts by weight of talcum powder, 7 parts by weight of calcium carbonate, 20 parts by weight of Barium sulfate, 3 parts by weight of non-halogen flame retardant and 2 parts by weight of defoamer are stirred in a stirred tank at 400-450r / min for 30-45 minutes to obtain a plastic mixture, and the plastic mixture is sucked by a vacuum suction machine into the hopper of the extruder;

[0052] Extrusion blank: the plastic mixture is sucked into the extruder barrel 1 through the feed port 2, the motor drive device 3 is started, and the motor drive device 3 drives the extrusion screw in the extruder barrel 1 to rotate, and the extruder barrel 1 The other end is provided with a connecting pipe 6, and the connecting pipe 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com