Method for producing hot-rolled steel coil

A technology of hot-rolled steel coils and production methods, applied in the direction of improving process efficiency, etc., can solve the problems of low plasticity and large strength margin of hot-rolled steel coils, reduce production costs, avoid bending cracking problems, reduce alloy The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

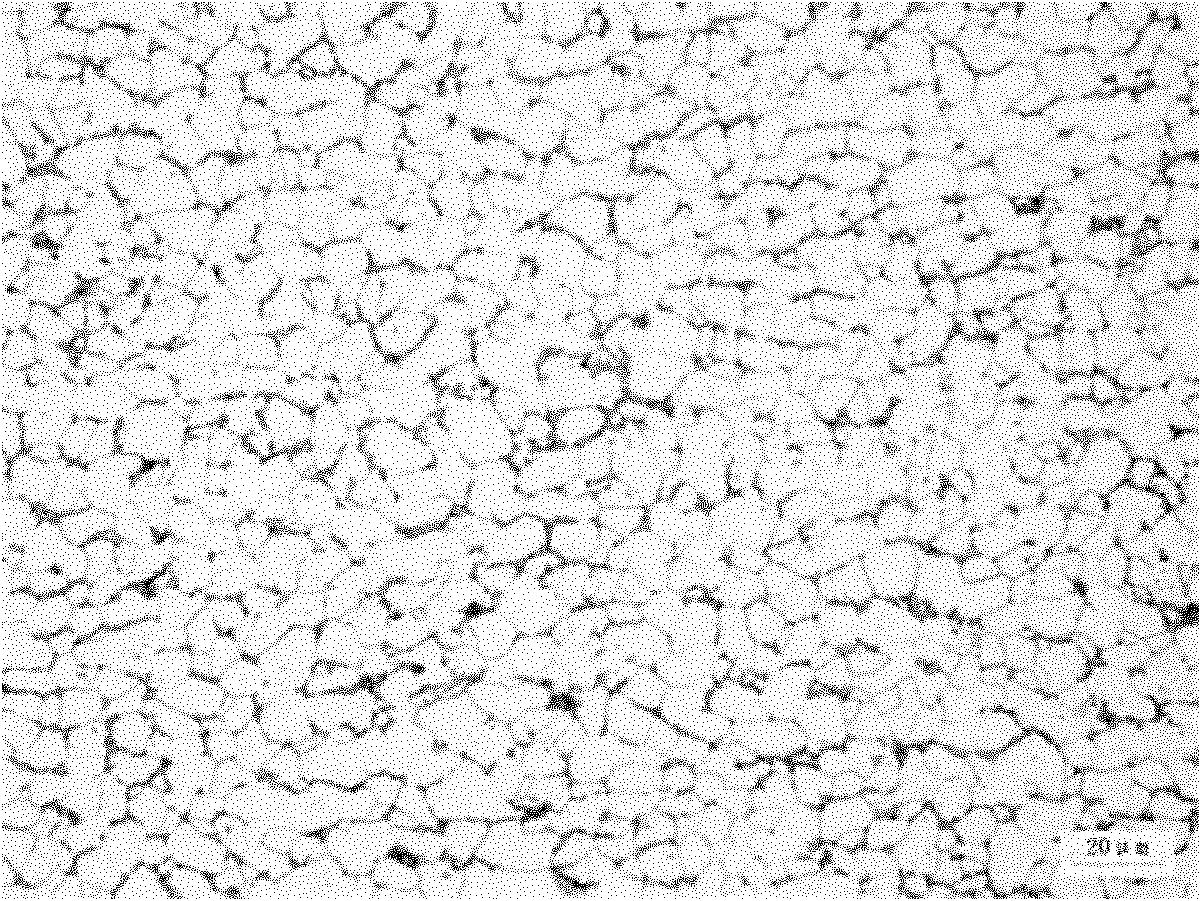

Image

Examples

Embodiment 1

[0049] 1) After the composition is designed, the molten iron is pretreated, then smelted in a converter, nitrogen and argon are switched, and the molten steel is obtained after tapping; the supplementary blowing is performed once before tapping, and the tapping time is 4.5 minutes; the alloy is added before tapping 4 / 5; Tapping double slag blocking, the slag thickness at the arrival station is 80mm; the whole process of argon blowing at the argon station takes 17 minutes;

[0050] 2) The weight percentages of the components of the above-mentioned molten steel after tapping are as follows: C 0.05%, Si 0.12%, Mn 0.40%, P 0.015%, S 0.010%, Als 0.020%, and the rest are iron and unavoidable impurities; The molten steel is continuously cast to obtain a slab, wherein the molten steel volume of the tundish is 25t and the liquid level is 550mm when the tundish is poured in the first continuous casting furnace; the molten steel volume is 15t and the liquid level is 350mm when the tundish...

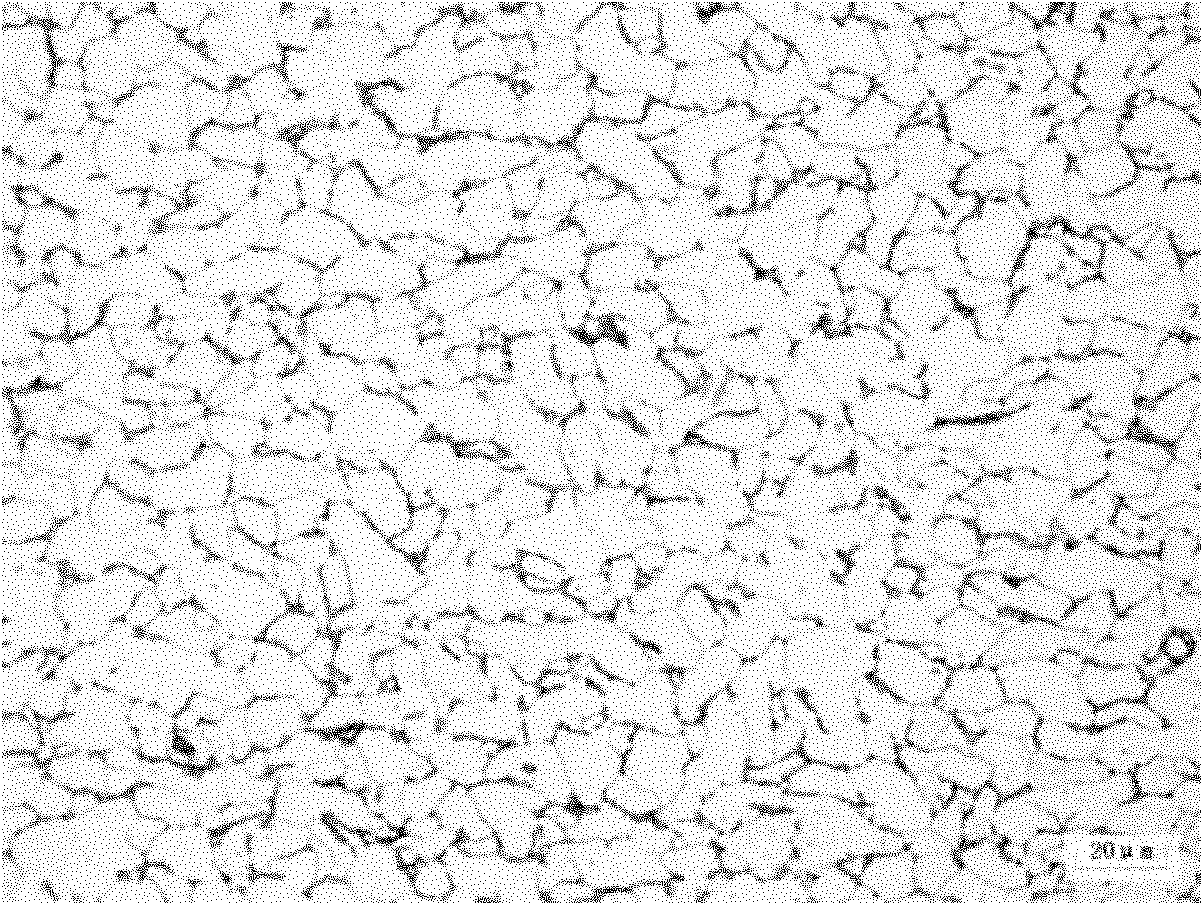

Embodiment 2

[0054] 1) After the composition is designed, the molten iron is pretreated, then smelted in the converter, nitrogen and argon are switched, and the molten steel is obtained from tapping; 0 times of supplementary blowing before tapping, and the tapping time is 6.0min; the alloy is added before tapping 4 / 5; Tapping double slag blocking, the slag thickness at the arrival station is 60mm; the argon station handles the whole process of blowing argon for 25 minutes;

[0055] 2) The weight percentages of the components of the above-mentioned molten steel after tapping are as follows: C 0.07%, Si 0.17%, Mn 0.51%, P 0.020%, S 0.015%, Als 0.025%, and the rest are iron and unavoidable impurities; The molten steel is continuously cast to obtain a slab, wherein the tundish molten steel volume is 30t and the liquid level is 560mm when the tundish is poured in the first continuous casting furnace; the tundish molten steel volume is 18t and the liquid level is 380mm when the tundish is quickly...

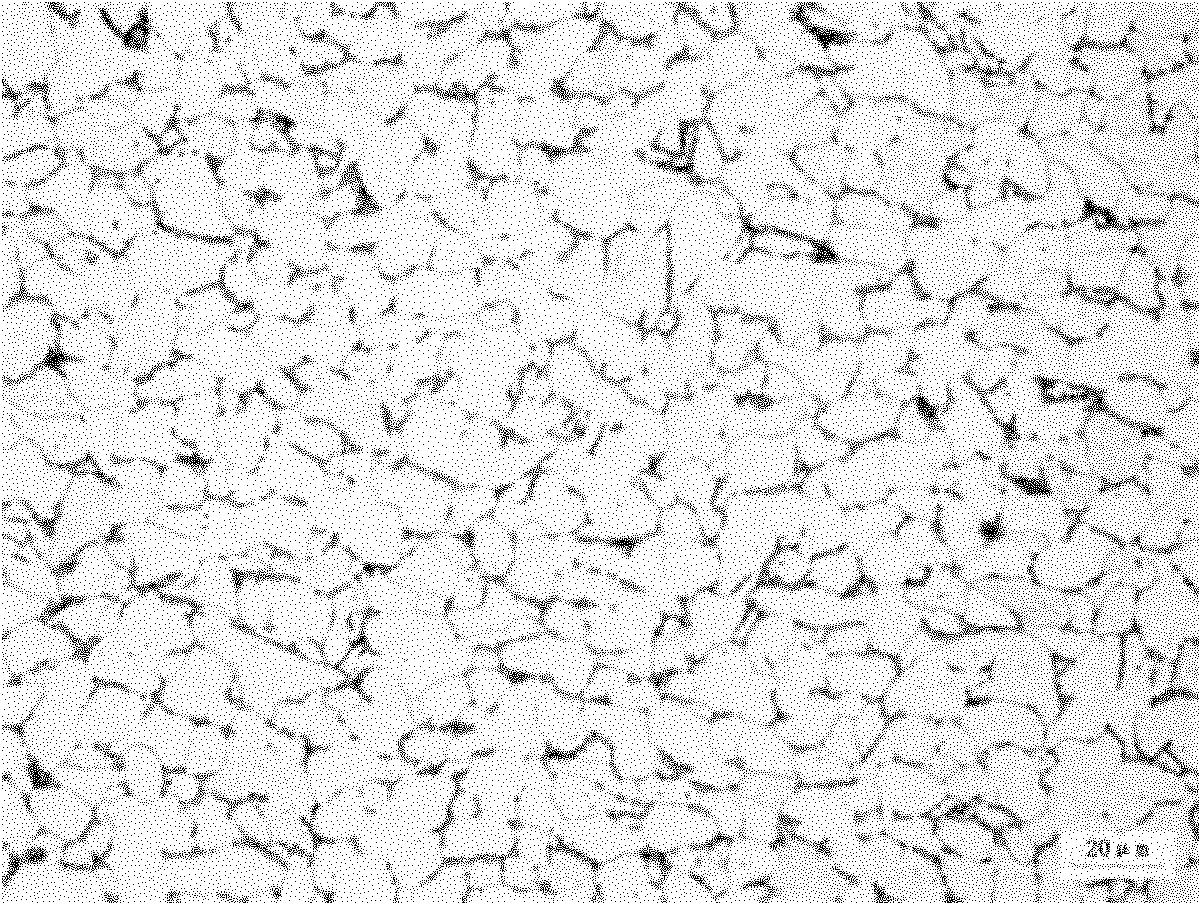

Embodiment 3

[0059] 1) After the composition is designed, the molten iron is pretreated, then smelted in the converter, nitrogen and argon are switched, and the molten steel is obtained after tapping; the supplementary blowing is performed once before tapping, and the tapping time is 8.0min; the alloy is added before tapping 4 / 5; Tapping double slag blocking, the slag thickness at the arrival station is 30mm; the whole process of argon blowing at the argon station is 30min;

[0060] 2) The weight percentages of the components of the above-mentioned molten steel after tapping are as follows: C 0.09%, Si 0.24%, Mn 0.62%, P 0.025%, S 0.020%, Als 0.040%, and the rest are iron and unavoidable impurities; The molten steel is continuously cast to obtain a slab, wherein the amount of molten steel in the tundish is 28t and the liquid level is 580mm when the tundish is poured in the first furnace of continuous casting; The amount of molten steel in the tundish is kept at 50t, and the liquid level is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com