Clamping stages and machine tools for thin wafer processing

A wafer and stage technology, applied to machine tools, metal processing equipment, grinding machines, etc., which are suitable for grinding workpiece planes, can solve the problems of reduced production efficiency, increased processing costs, and increased procedures, so as to improve production efficiency and save High cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

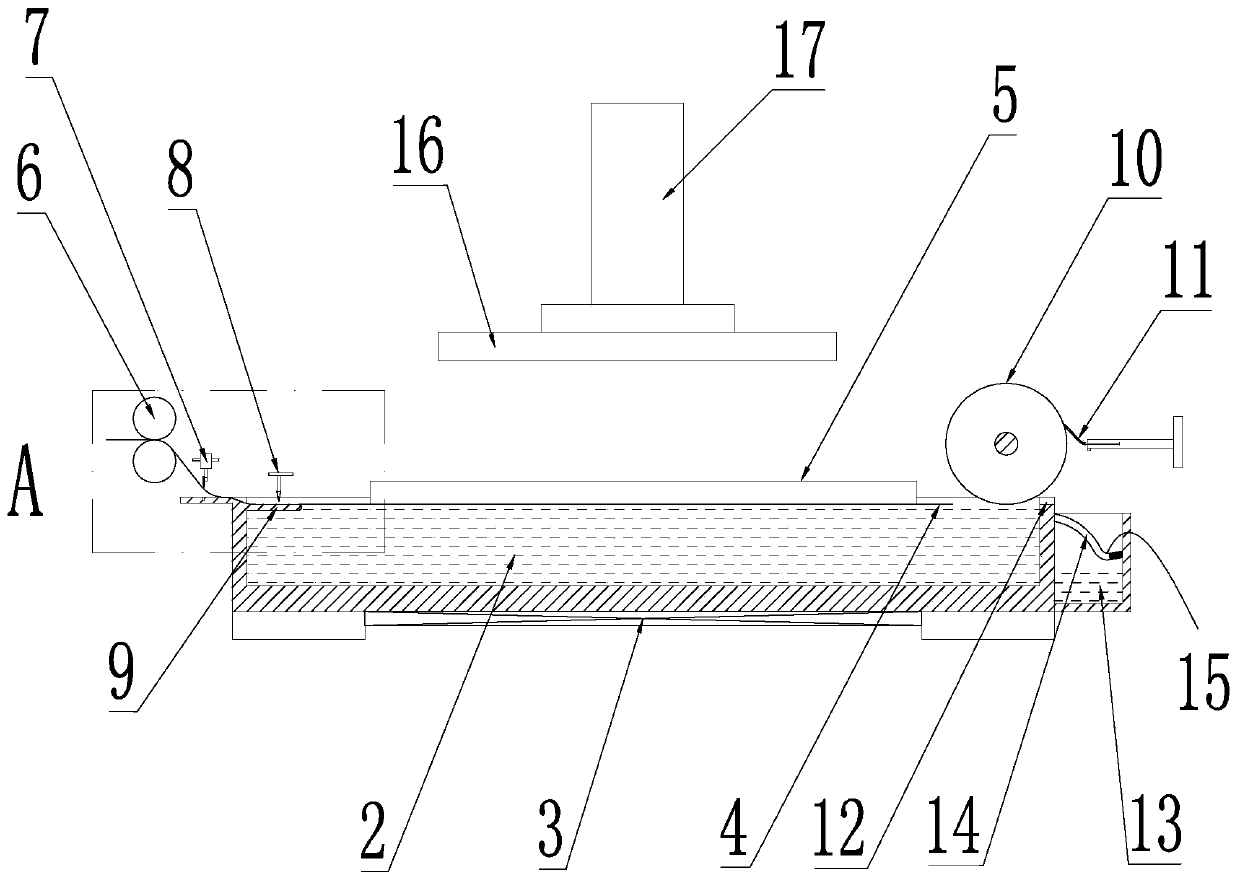

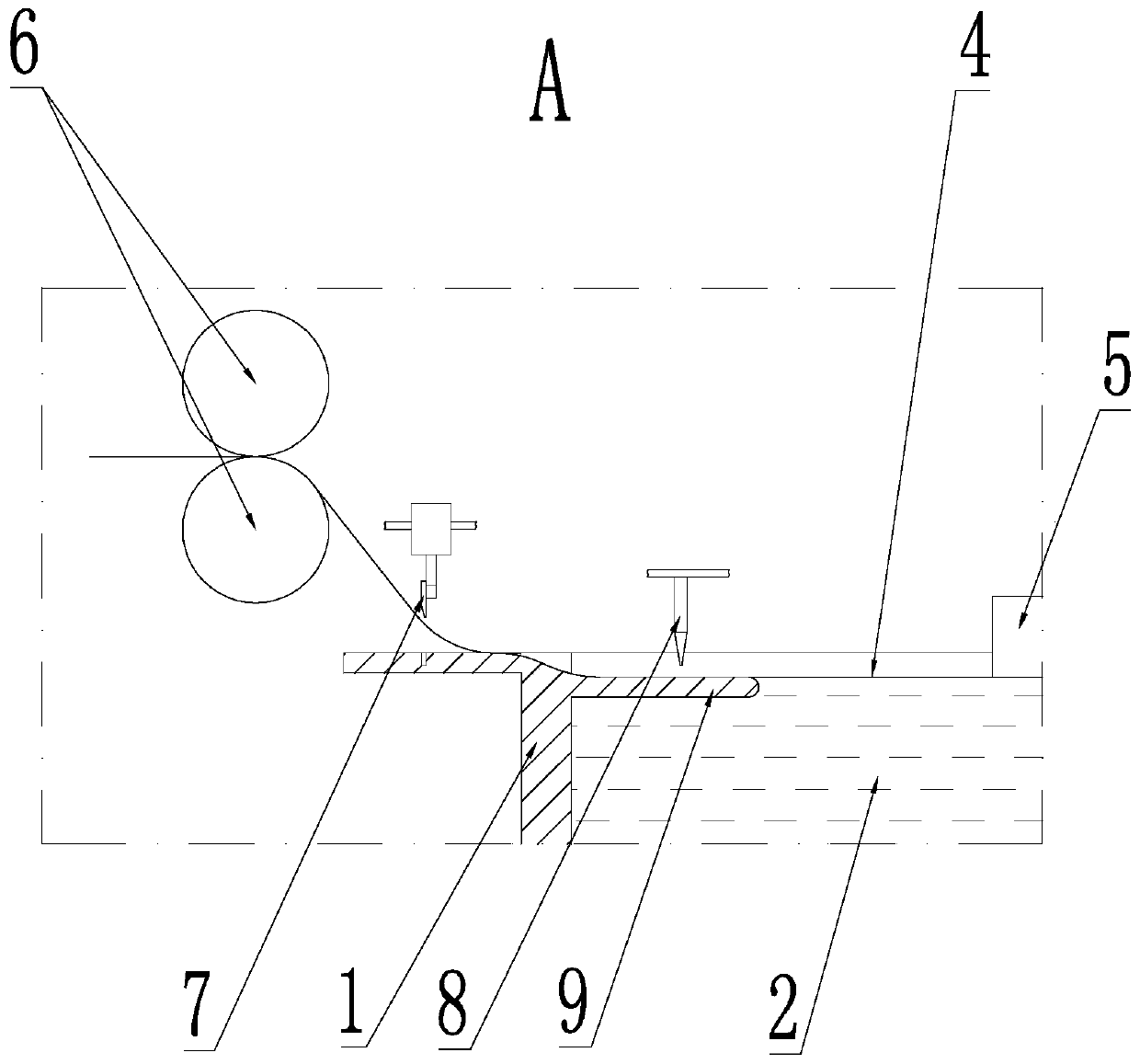

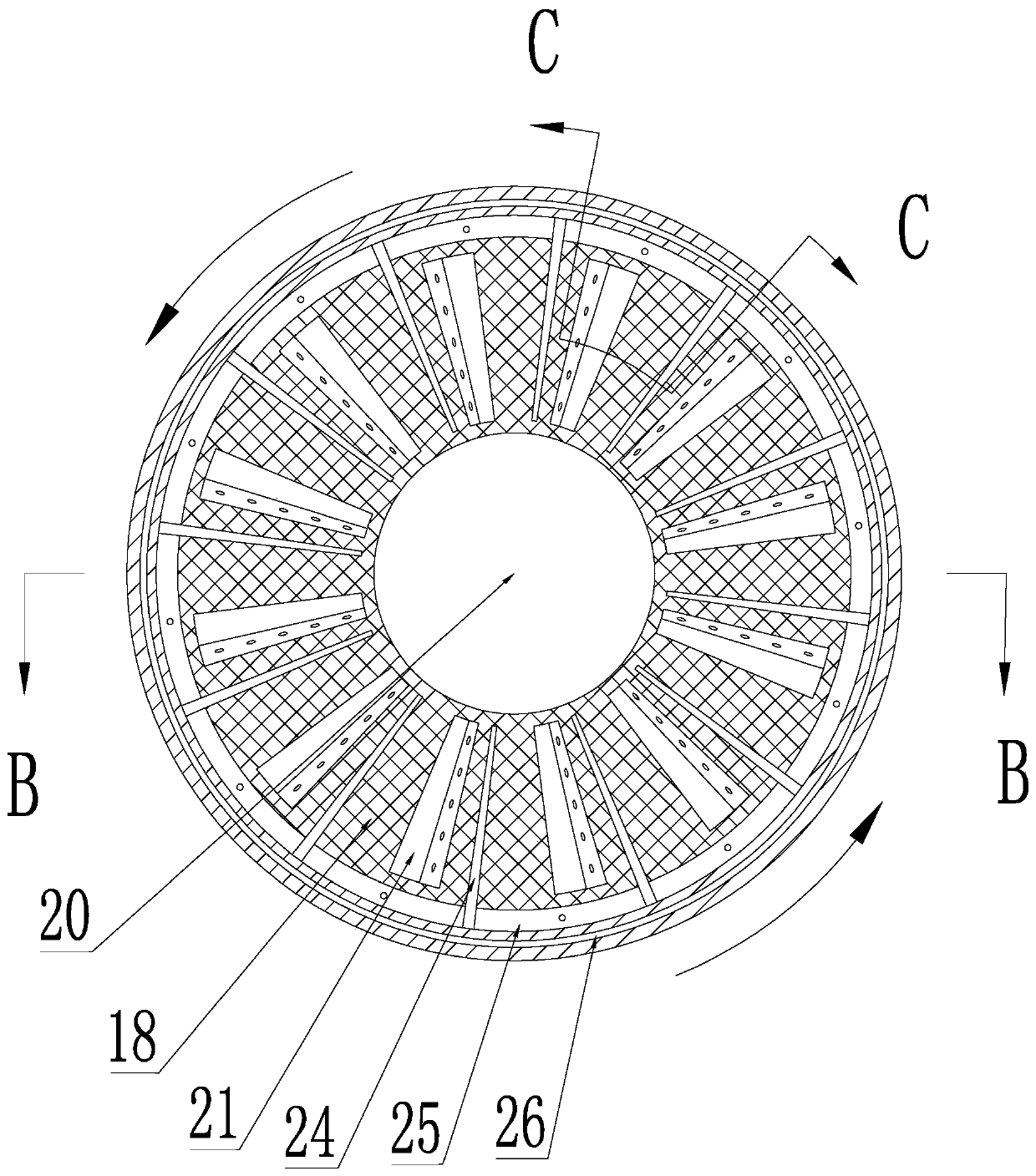

[0028] As a preference, the above-mentioned clamping stage includes a tank body 1, a magnetorheological fluid 2 is arranged in the tank body 1, and a bottom for driving the magnetorheological fluid 2 to solidify or reset to a fluid state is provided at the bottom of the tank body 1. The excitation device 3, the excitation device 3 refers to a device for generating a magnetic field, the magneto-rheological fluid 2 is solidified by the magnetic field, and when the excitation device 3 is powered off so that the magnetic field disappears, the magneto-rheological fluid 2 is reset again fluid state. The tank body 1 is provided with a paper feeding mechanism, and the paper feeding mechanism periodically supplies a single sheet of paper 4 into the tank body 1, and the paper sheet 4 floats on the liquid surface of the magnetorheological fluid 2. A paper pumping mechanism is provided on the other side of the tank body 1 away from the paper feeding mechanism. When the wafer 5 to be proce...

Embodiment 2

[0030] The general structure is the same as that of Embodiment 1, the difference is that the paper feeding mechanism includes a driving roller set 6 and a cutter assembly 7 for cutting paper, and the driving roller set 6 clamps the strip-shaped paper and drives the strip The shaped paper moves along its own length direction. The cutter assembly 7 is set on the tank body 1 and is located between the driving roller group 6 and the tank body 1. The strip-shaped paper is cut by the cutter assembly 7 to form several sheets. paper sheets 4, and each paper sheet 4 floats on the liquid surface of the magnetorheological fluid 2 in the tank body 1 in sequence.

[0031] Specifically, the driving roller set 6 includes a driving roller and a driven roller, the axes of the driving roller and the driven roller are parallel to each other, and a clamping space for clamping paper is formed between the driving roller and the driven roller. The above-mentioned driving rollers and driven rollers a...

Embodiment 3

[0034] The general structure is the same as that of Embodiment 2, the difference is that: the tank body 1 is provided with a nozzle 8, the nozzle 8 is located on the side of the cutter assembly 7 close to the inner cavity of the tank body 1, and the cutter assembly 7 is formed by shearing The paper sheet 4 floats on the liquid surface of the magnetorheological fluid 2 after being sprayed by the nozzle 8 . Specifically, the cutter assembly 7 includes a cutter and a knife frame, the knife frame is fixed to the tank body 1, and the knife frame is provided with a driving cylinder for driving the cutter to move.

[0035] Preferably, the nozzle 8 sprays water mist for wetting the paper sheet 4 .

[0036] Further, the nozzle 8 sprays a liquid bonding glue, through which the wafer 5 is bonded to the cured magnetorheological fluid 2 , that is, bonded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com