Pile foundation pouring system for building

A technology for construction and pile foundation, applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of reduced pile foundation stability, high difficulty in placing, and reduced bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

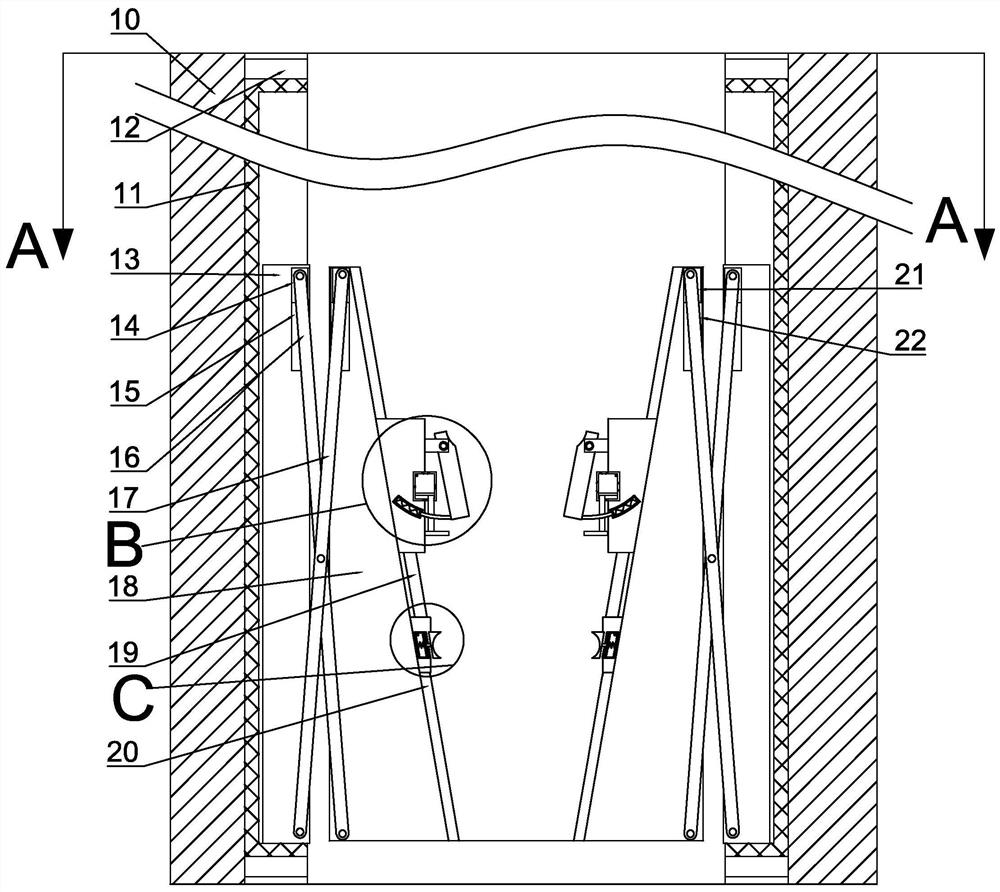

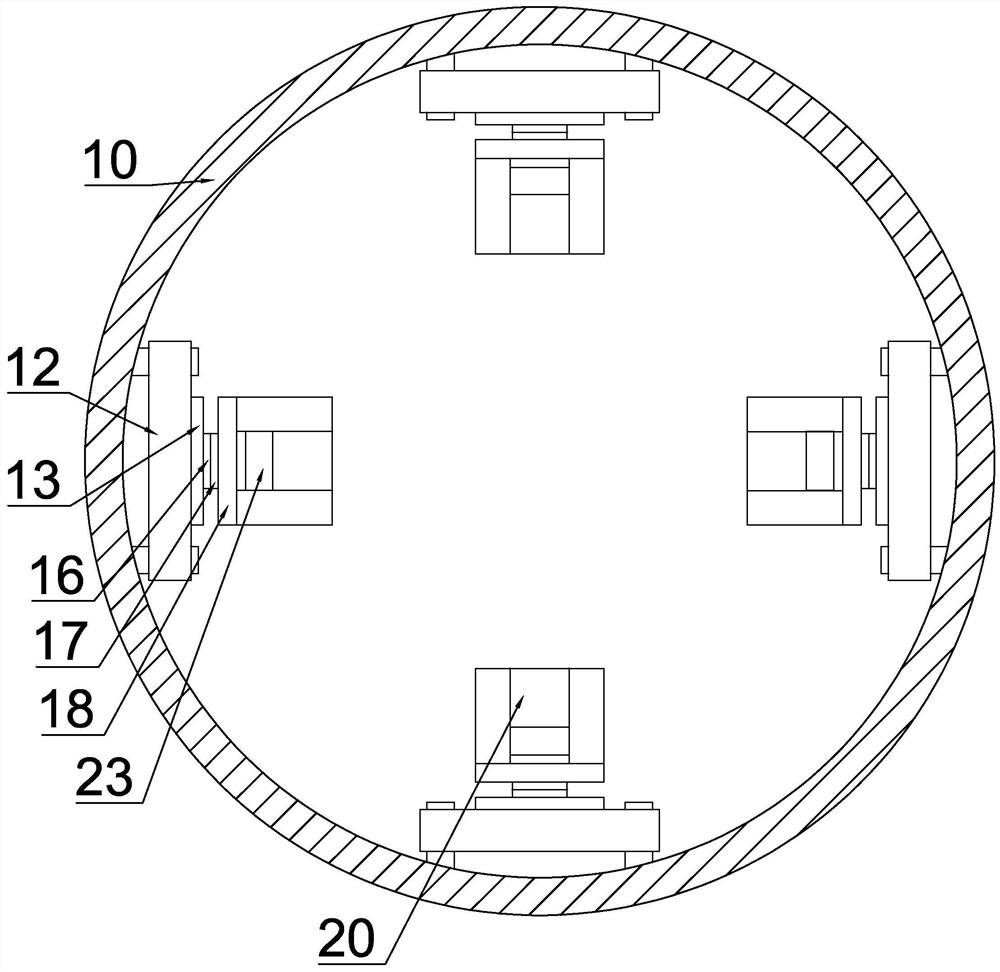

[0025] Such as figure 1 As shown, a building pile foundation pouring system includes a steel casing wall 10, and the inner wall of the steel casing wall 10 is provided with four detachable bolt holes 12 that can be connected by bolts and nuts, and each bolt hole 12 is fixed Lifting grooves 11 are provided, and lifting slides 13 are arranged to slide up and down in the lifting grooves 11. Each lifting slide 13 is provided with a size adapting device, and the size adapting device is used to adjust the distance with the steel cage.

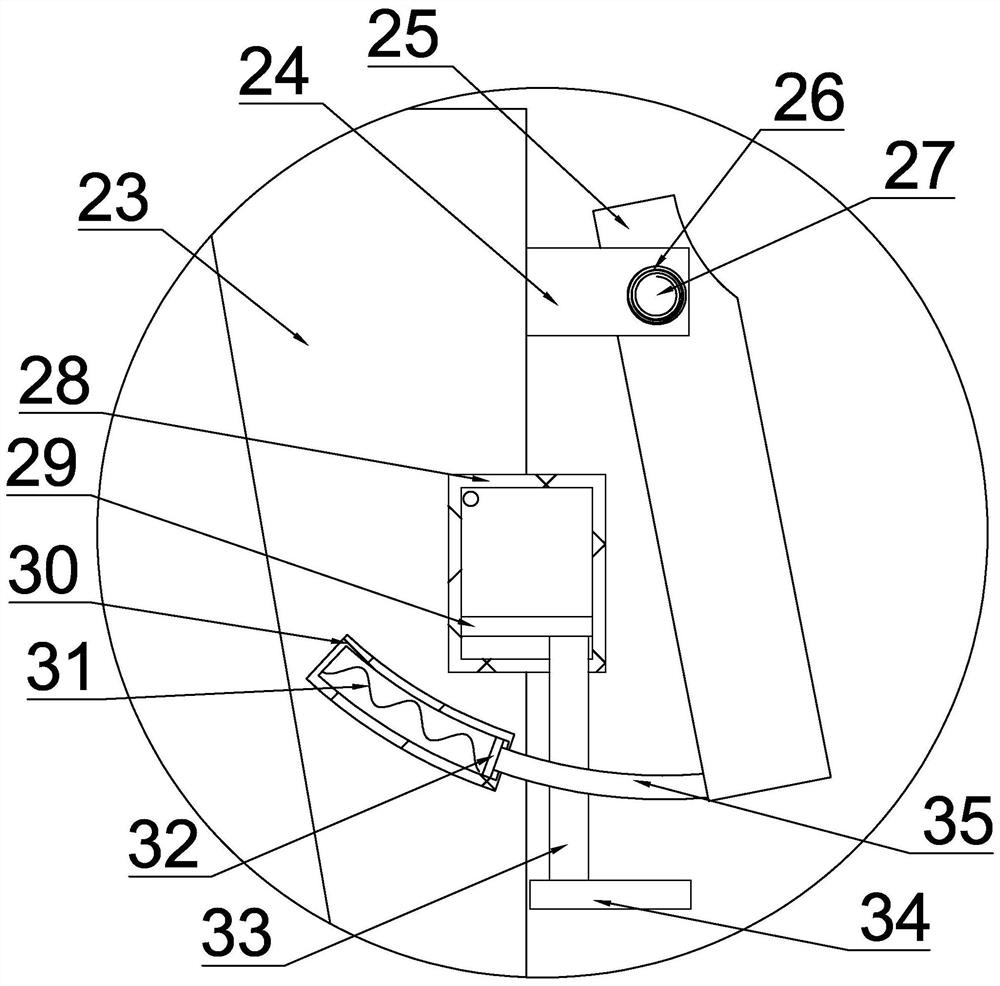

[0026] Such as figure 1 with figure 2 As shown, the size adaptation device includes a hinge block groove 15 arranged on the end surface of each lifting slide 13 close to the center of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com