Wrapped heat-conducting grounding elastic piece and electronic device

A technology of electronic equipment and elastic parts, which is applied to grounding circuits, modification through conduction and heat transfer, and electrical components. It can solve the problems of easy bending and cracking of metal coatings, improve surface thermal conductivity, reduce production costs, and overcome problems easily. The effect of bending and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

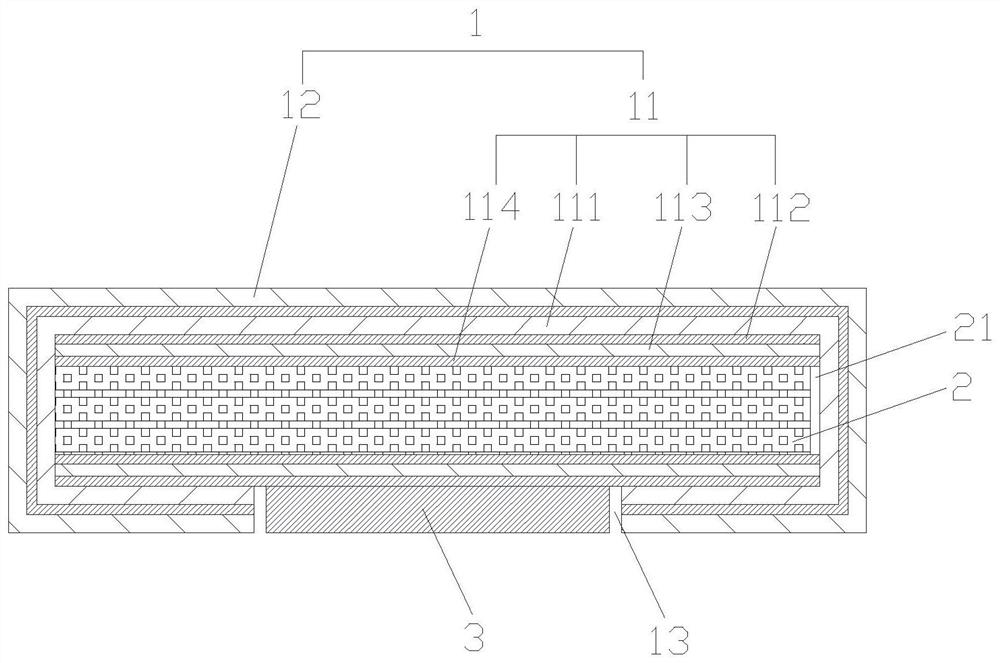

[0033] Such as figure 1 As shown, a wrap-type thermally conductive grounding elastic member includes: a shielding film 1, a high temperature resistant elastic body 2, and the shielding film 1 is provided with a cavity for wrapping the elastic body 2 (not shown in the figure).

[0034] Preferably, the shielding film 1 includes a supporting film layer 11 and a copper foil layer 12 from inside to outside, and the outer surface of the copper foil layer 12 is provided with a transition metal layer and a conductive metal layer in sequence from inside to outside.

[0035] Preferably, the supporting film layer 11 includes a PI film layer 111 , a first adhesive layer 112 , and a PET film layer 113 from outside to inside. The PI film layer 111 and the copper foil layer 12 are coated on the surface of the copper foil layer 12 by adhesive bonding, melting and solidification, or liquid PI for curing and compounding. The combination of the copper foil layer 12 and the PI film layer 111 imp...

Embodiment 2

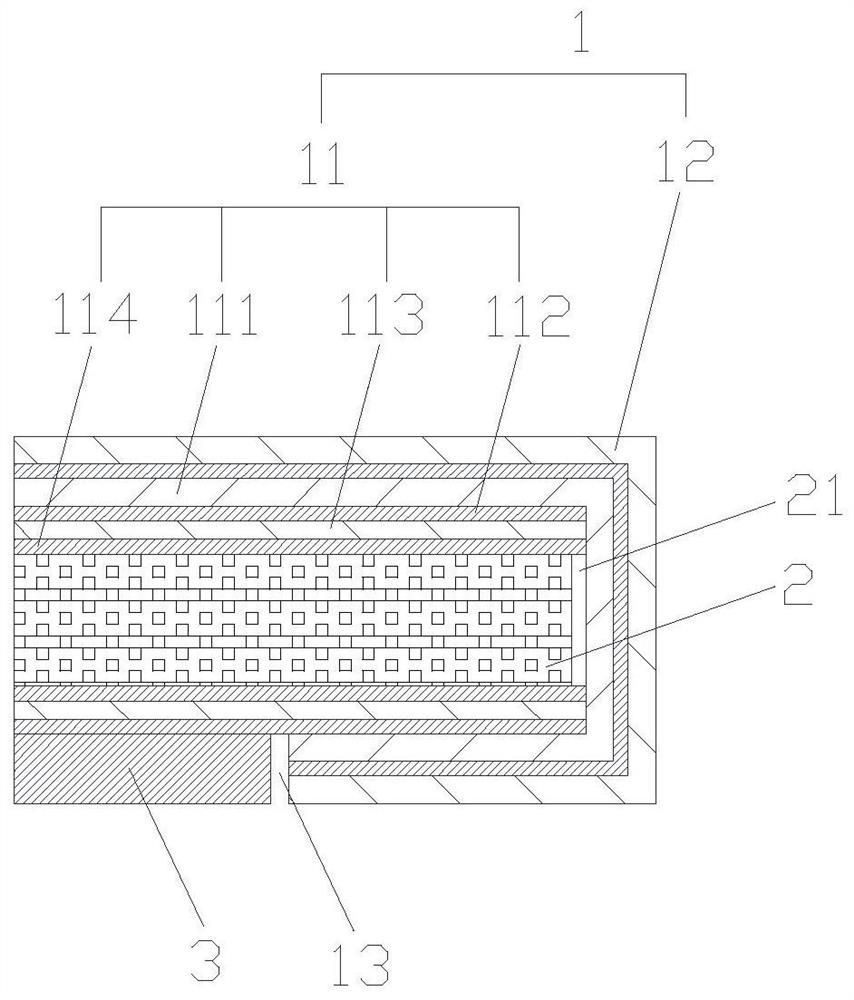

[0045] Such as figure 2 As shown, the difference from Embodiment 1 is that Embodiment 2 is a half structure of Embodiment 1, and the structure of Embodiment 1 can be produced during production, and then cut from the middle.

[0046] The present invention also discloses an electronic device adopting the above-mentioned wrap-type thermally conductive grounding elastic member. The electronic device also includes a circuit board or a metal shell for electrically connecting the wrapped-type heat-conductive grounding elastic member. The circuit board or metal shell is bonded and fixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com