Fracturing equipment for coal bed gas exploiting

A coalbed methane and fracturing technology, which is applied in the field of coalbed methane mining and fracturing equipment, can solve the problems of affecting the life of high-pressure pumps, affecting economic benefits, and large volume of pressure pumps, so as to reduce local heat generation, simple design structure, and reduce friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

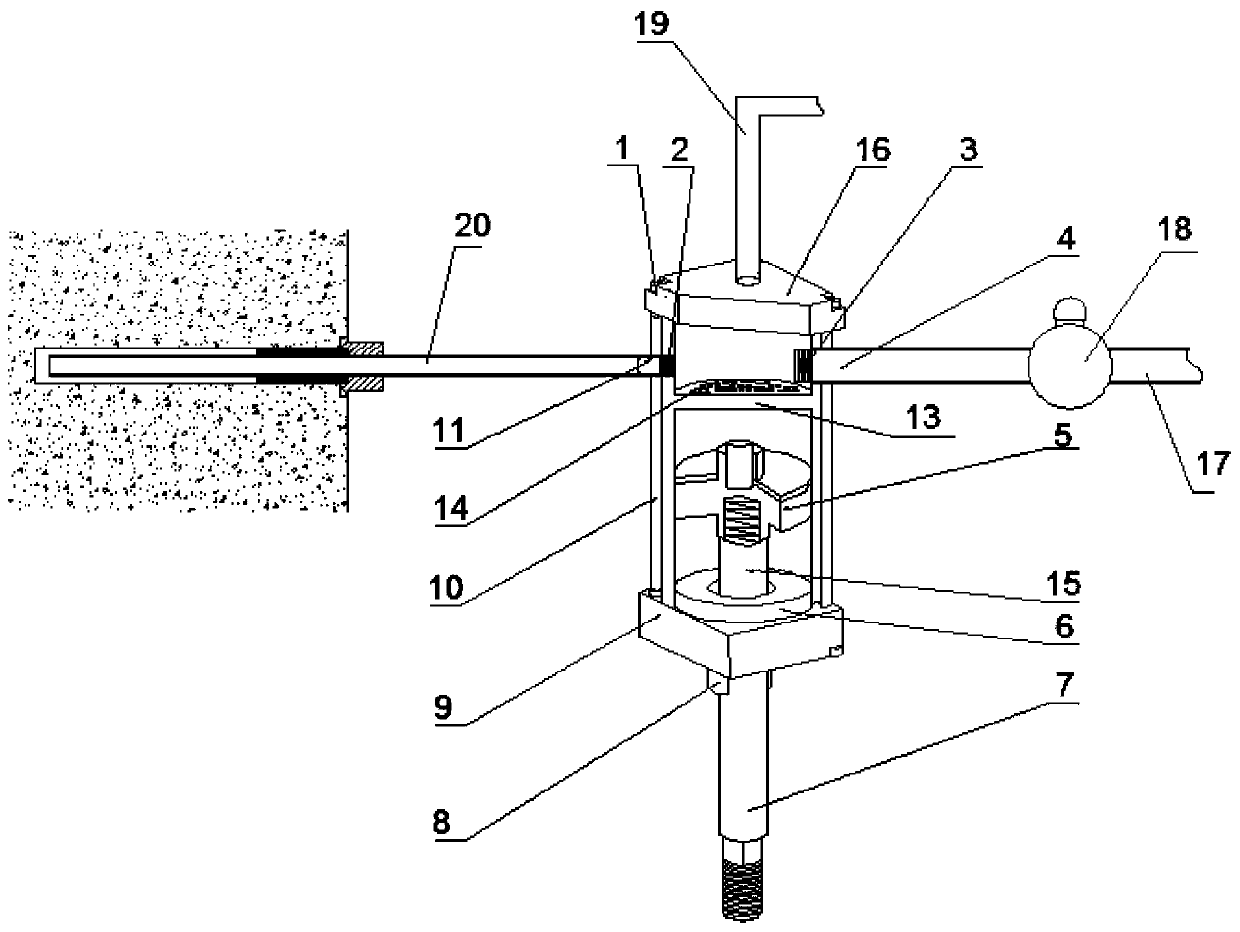

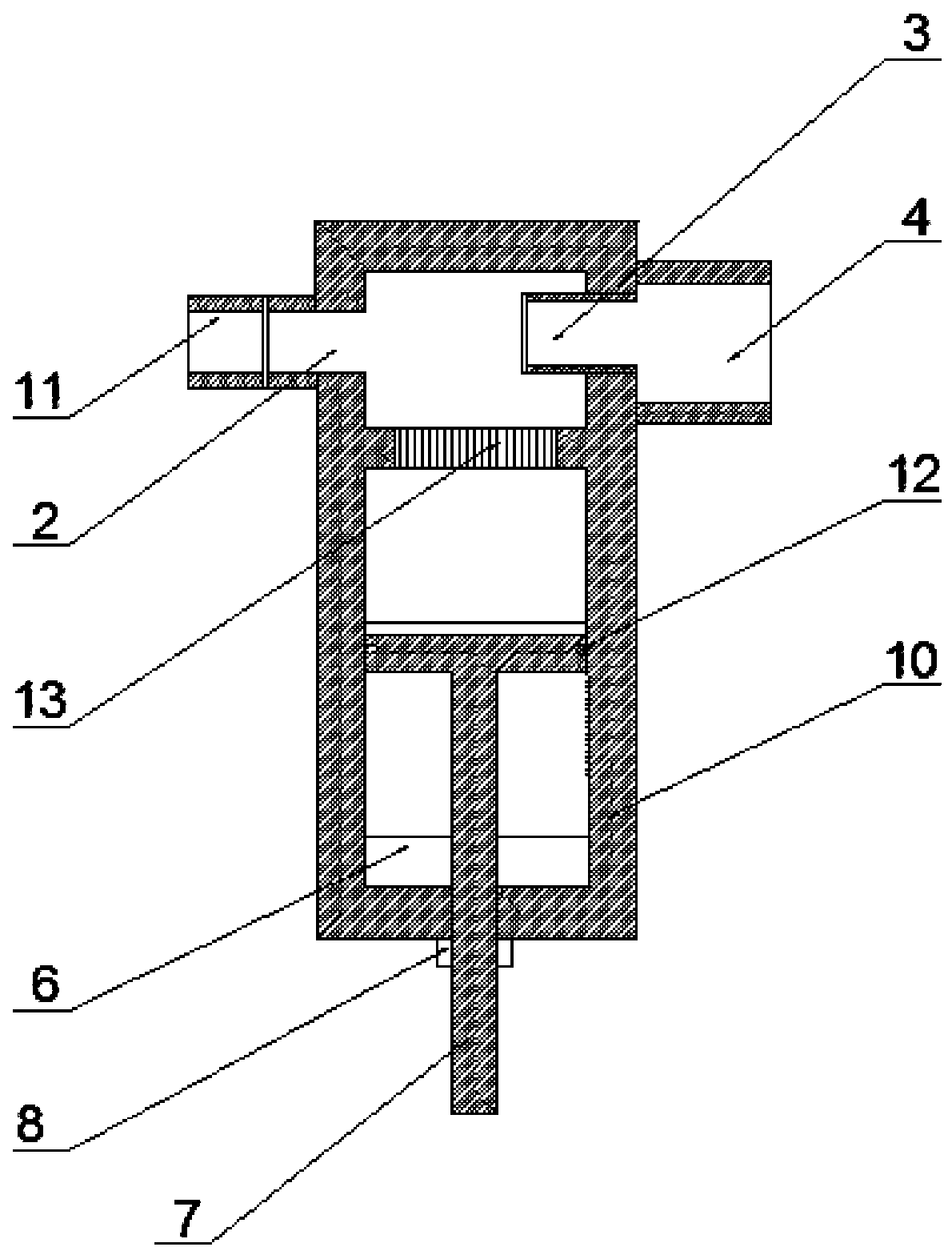

[0024] see Figure 1~2 , in an embodiment of the present invention, a coalbed methane mining fracturing equipment includes a pressure stabilizing pump 18, a high pressure water fracturing supply equipment, a pressurized mixing mechanism, a sand supply mechanism and a fracturing pipe 20, wherein the pressure stabilizing pump The input end of the pump is connected to the output end of the high-pressure water fracturing supply equipment, and it is characterized in that the output end of the pressure stabilizing pump 18 is connected to the feed pipe 4 of the pressurized mixing mechanism, and the pressurized mixing The mechanism also adopts the sand supply pipe 19 to be connected with the sand supply mechanism, and the end of the discharge pipe 11 of the pressurized mixing mechanism is connected to the fracturing pipe 20, and the fracturing pipe 20 extends into the pressure of the coal seam. In the fractured borehole; the pressurized mixing mechanism fully mixes and pressurizes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com