Production method of composite slide plate for bridge bearing, and friction pair for bridge bearing

A technology of bridge bearings and friction pairs, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of poor bonding performance, low mechanical strength, high compression creep of bearings, etc., and achieve stable friction coefficient and load transmission Uniformity, the effect of improving the load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

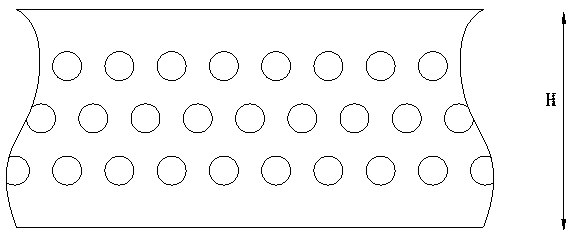

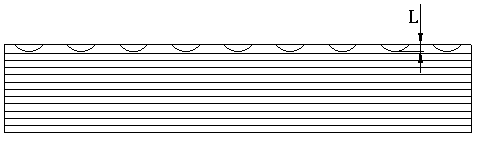

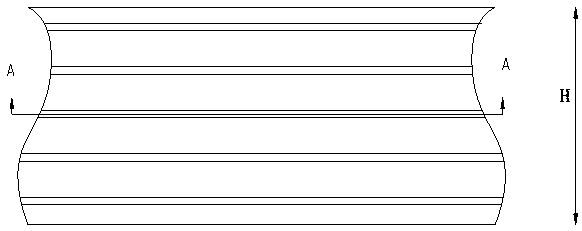

[0049] Weave polyester fiber into plain fiber cloth, soak the woven fiber cloth with 0.5% coupling agent for 0.5h, and dry at 105°C for 1h; mix and modify the resin matrix, wherein the modified resin matrix is unsaturated polyester, friction The performance modifier is molybdenum disulfide, and the ratio of molybdenum disulfide to the total amount of the modified resin matrix is 5%; the woven fiber cloth is cut and weighed, and the woven fiber cloth is soaked with the modified resin matrix, and each layer of fiber cloth is evenly soaked into the modified resin matrix. Resin matrix, wherein the woven fiber cloth is 70 parts by weight, and the modified resin matrix is 30 parts; 10 layers of lamination are put into the molding mold, and then the composite material is pressed at 80°C with a molding pressure of 2MPa, and the surface A spherical structure oil storage tank is adopted; the thickness of the composite plate measured after demoulding is 4.5 mm.

Embodiment 2

[0051] Weave aramid fibers into twill fiber cloth, soak the woven fiber cloth with 1% coupling agent for 1 h, dry at 110°C for 2 h, cut the woven fiber cloth, and carry out mixed modification for the resin matrix, wherein the modified resin matrix is unsaturated polystyrene Ester, the friction performance modifier is polytetrafluoroethylene powder, and the ratio of polytetrafluoroethylene micro powder to the total amount of modified resin matrix is 20%; the modified resin matrix is used to impregnate the woven fiber cloth and each layer of fiber cloth is evenly infiltrated with the modified resin The matrix, wherein the weight of the woven fiber cloth is 50 parts, and the modified resin matrix is 50 parts; the laminated 18 layers are put into the molding mold, and then the composite material is pressed at 150°C with a molding pressure of 5MPa, and the surface crosses shaped structure oil storage tank; the thickness of the composite plate measured after demoulding is 6.8...

Embodiment 3

[0053] Weave polyphenylene sulfide fibers into plain fiber cloth, soak the woven fiber cloth with 1.5% coupling agent for 1 hour, dry it at 120°C for 1.5 hours, cut the woven fiber cloth, and carry out mixed modification for the resin matrix, wherein the modified resin matrix It is epoxy polyester, and the friction modifier is a mixture of polytetrafluoroethylene micropowder and molybdenum disulfide, wherein polytetrafluoroethylene micropowder accounts for 10% of the total amount of the modified resin matrix, and molybdenum disulfide accounts for the total amount of the modified resin matrix. 3% of 3%; impregnate the woven fiber cloth with the modified resin matrix and each layer of fiber cloth is evenly infiltrated with the modified resin matrix, wherein the woven fiber cloth is 60 parts by weight, and the modified resin matrix part is 40 parts; laminate 30 Put the layer into the forming mold, and then press the composite material with a forming pressure of 4MPa at 120°C, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com