Feed processing device

A feed processing and frame installation technology, which is applied to heating devices, feed, lighting and heating equipment, etc., can solve problems such as easy clogging of cutting devices, large volume of roughage, and cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

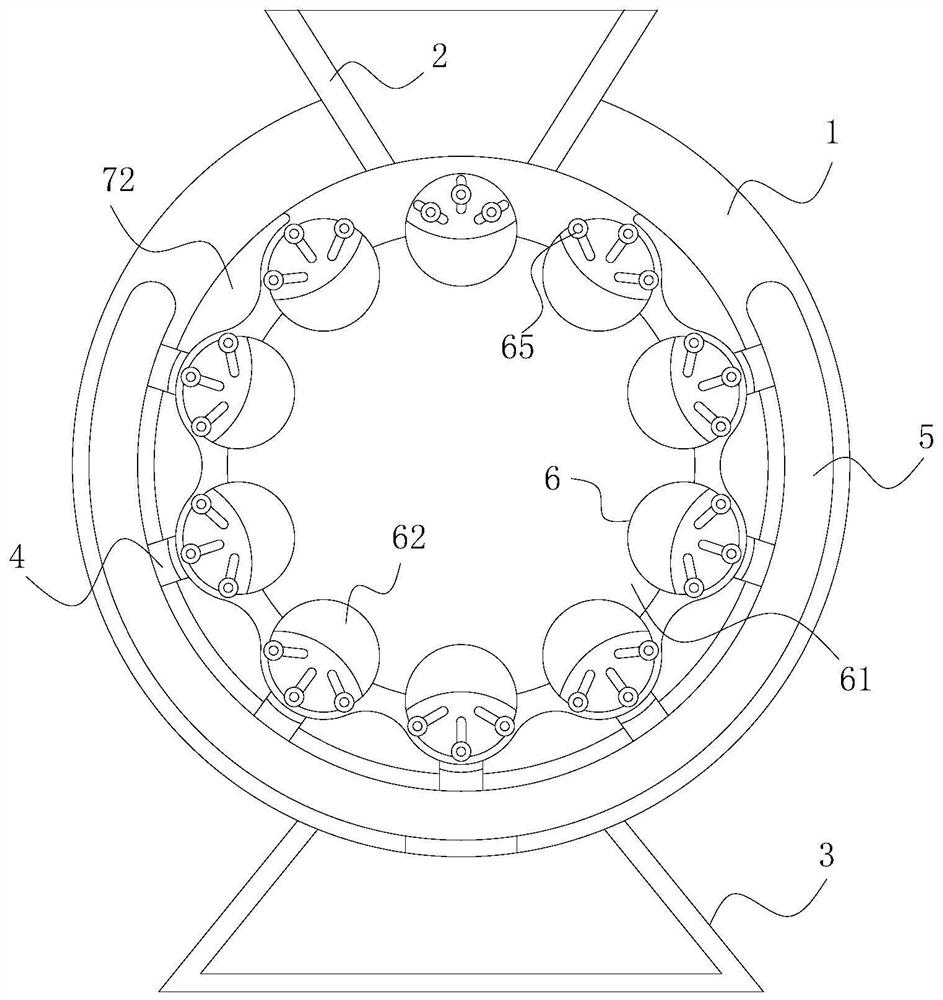

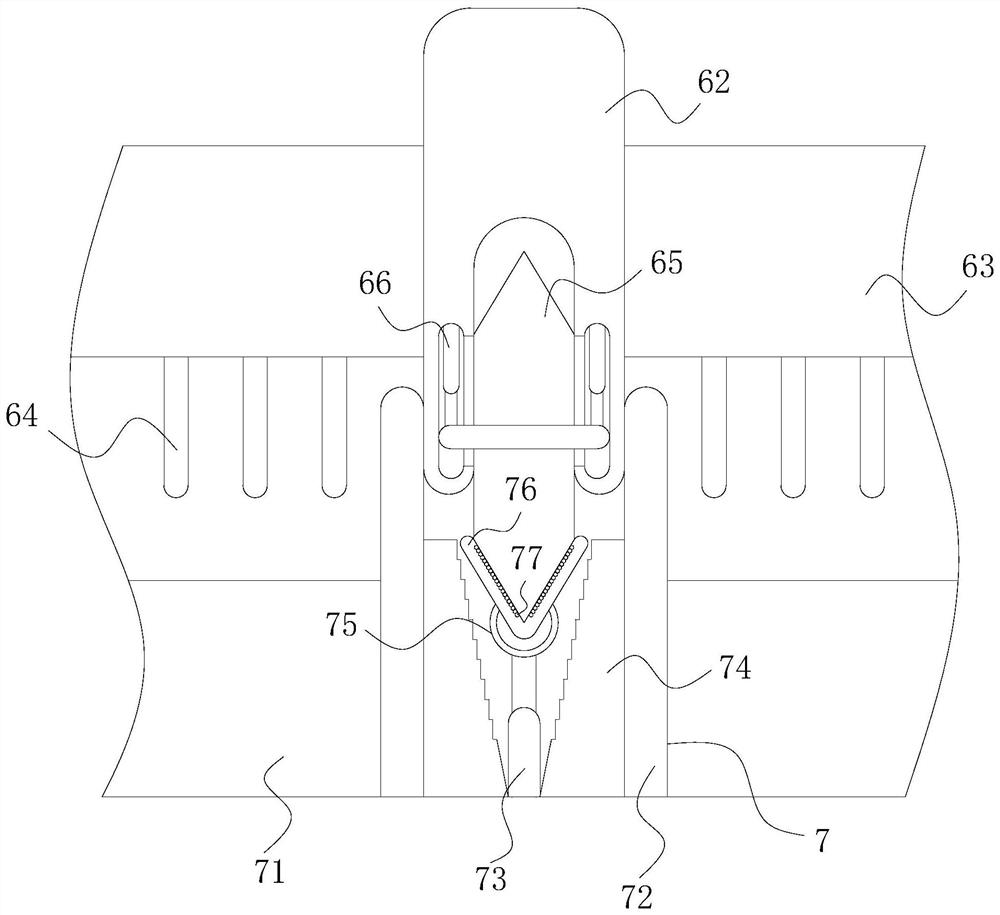

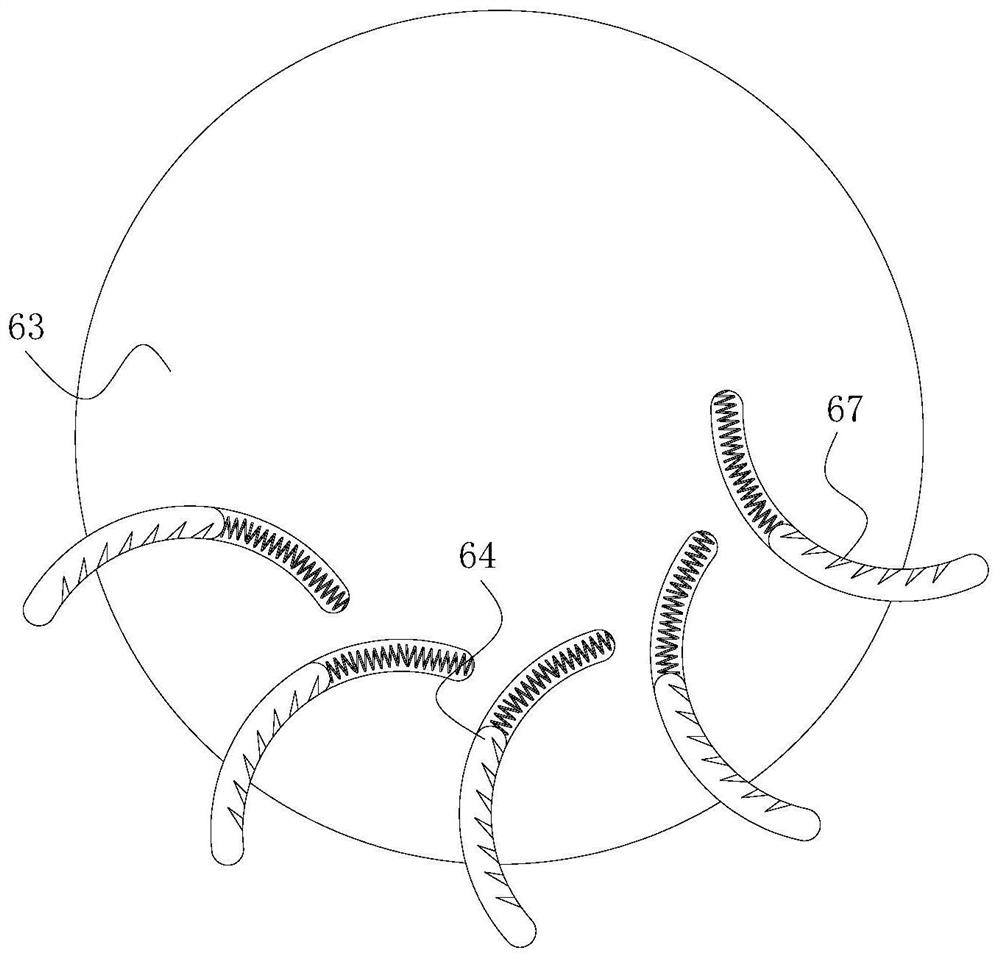

[0018] use Figure 1-Figure 4 A feed processing device according to one embodiment of the present invention will be described below.

[0019] Such as Figure 1-Figure 4 As shown, a feed processing device according to the present invention includes an installation frame 1, a material inlet 2, a base 3, a filter hole 4, a gathering tank 5, a cutting mechanism 6 and a heating mechanism 7; the base 3 is placed on the ground Above, the upper end of the base 3 is fixedly connected with an installation frame 1; the upper end of the installation frame 1 is fixedly installed with a material inlet 2, the cross section of the installation frame 1 is circular, and the interior of the installation frame 1 is provided with a cutting mechanism 6; The cutting mechanism 6 includes a rotating roller 61, a mounting plate 62, a connecting rod 63, a scraper 64, a cutting wheel 65, a telescoping rod 66 and an evenly divided opening 67; The outer wall of the rotating roller 61 is evenly fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com