Composite kitchen knife and assembling method thereof

An assembly method and technology for kitchen knives, applied in the field of kitchen knives, can solve the problems of insufficient sharpness, high price, poor performance, etc., and achieve the effects of convenient processing, stable connection performance, and guaranteed service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

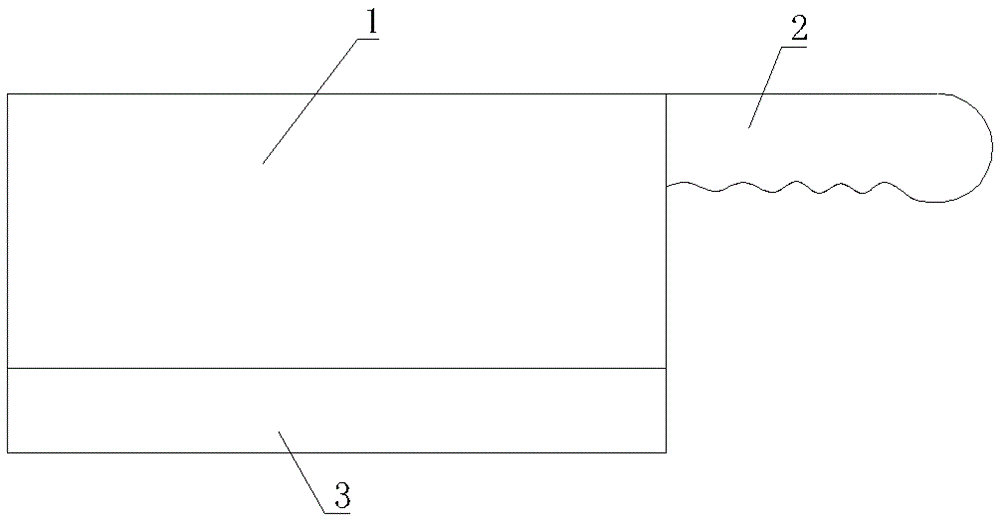

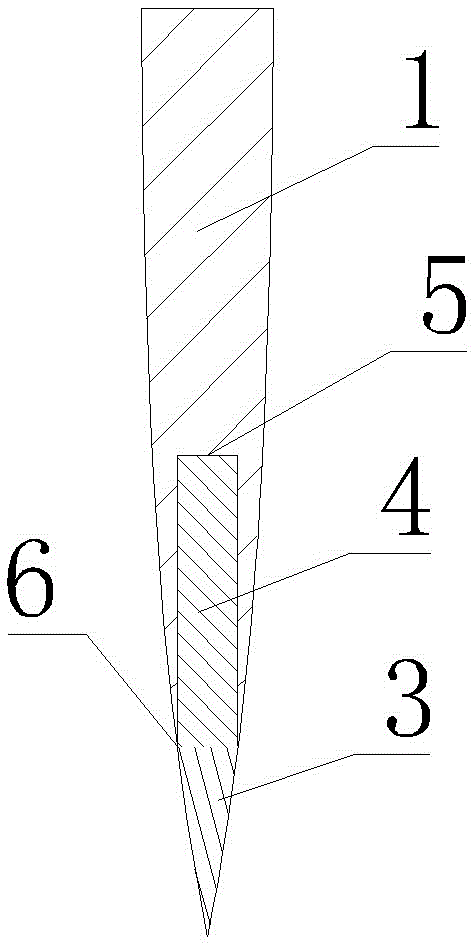

[0021] See figure 1 , figure 2 , a composite kitchen knife of the present invention, comprising a knife body 1 connected to the knife body 1 and a handle 2 arranged on the rear side of the knife body 1, and also includes a blade, the blade includes a cutting edge 3 and a connecting portion 4, and the lower end of the blade body 1 is provided with The groove 5 matched with the connection part 4, the connection part 4 can be embedded in the groove 5, the blade and the blade body 1 are welded and connected, the blade body 1 is made of spring steel or tool steel, and the blade is made of tungsten steel or powder steel; The upper part of the blade is the connecting part 5, the lower part of the blade is the cutting edge 3, and the cutting edge 3 is a shape that gradually becomes thinner from top to bottom; It is the back edge of the knife, and the back edge of the knife is a straight thick edge; the junction 6 between the blade and the cutting edge transitions smoothly; the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com