Copper base alloy pipe containing silicon and aluminium and preparation method thereof

A technology of copper-based alloy and alloy tube, which is applied in the field of non-ferrous metal processing, can solve the problems of polluted air, emission of lead dust, harmfulness to human body, etc., and achieve the effect of inhibiting lead dissolution and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

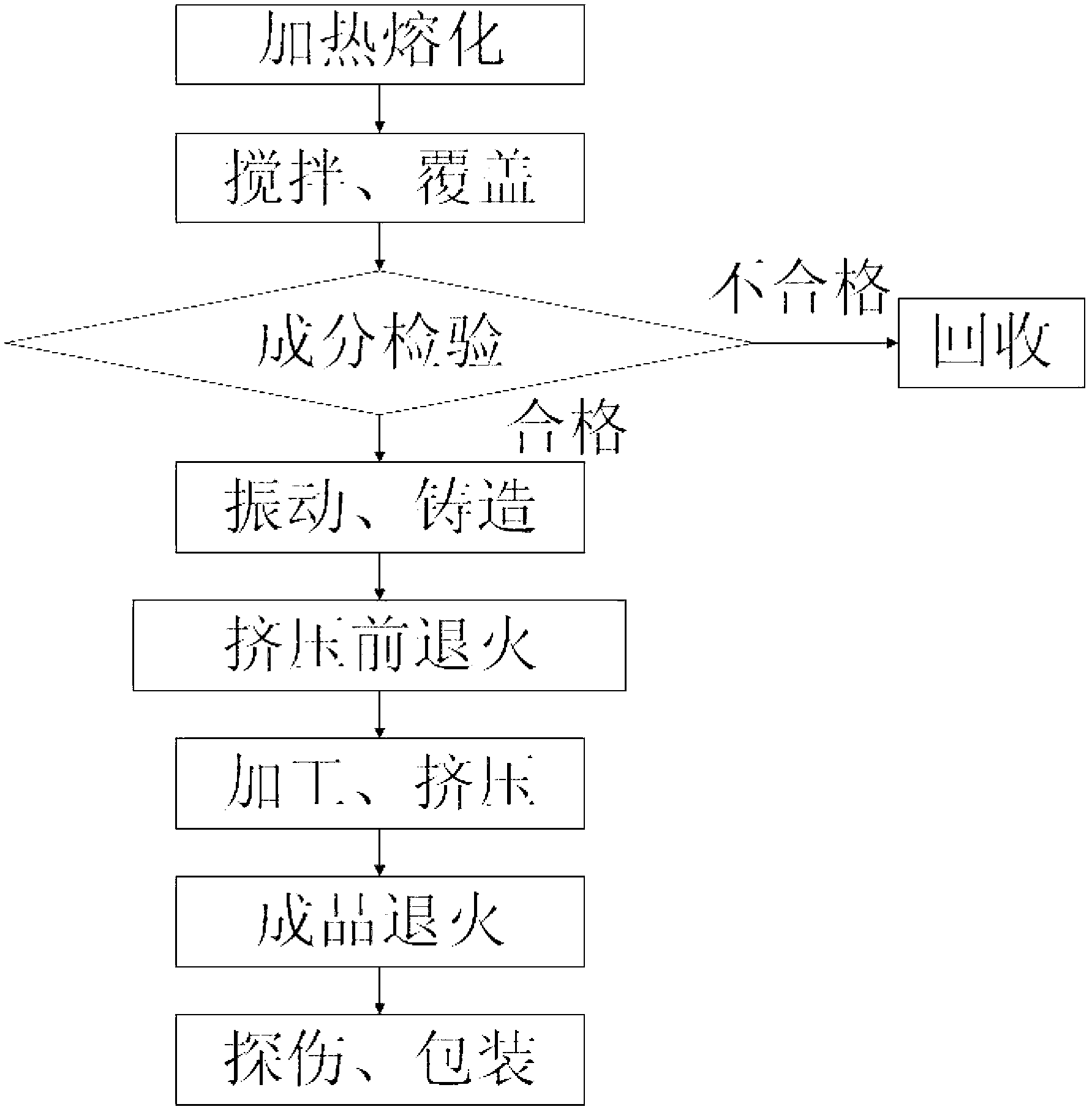

[0026] The preparation method of the copper-based alloy tube of embodiment 1, such as figure 1 As shown, including the following steps:

[0027] 1) Place the electrolytic copper, silicon, aluminum, and zinc in a power frequency electric furnace according to the ratio, heat it to 1200-1250 degrees, and heat it to 1150 degrees after being completely melted;

[0028] 2) After fully stirring the completely melted alloy liquid with a graphite rod, cover it with high-purity flake graphite powder to prevent it from oxidizing, the thickness is 10-15cm;

[0029] 3) After holding for 1-1.5 hours, use the German Spike direct-reading spectrometer to conduct 3-6 component inspections on the samples taken out of the power frequency electric furnace to confirm that the alloy composition is within the specified range;

[0030] 4) After further holding for 50-60 minutes, the temperature is raised to 1200 degrees again, and the vibration device of the power frequency electric furnace is turned on, and ...

Embodiment 2

[0036] A copper-based alloy tube containing silicon and aluminum, the mass percentage composition of which is: copper 76%; silicon 0.05%; aluminum 1.8%; the balance is zinc.

[0037] The preparation method of the silicon-and-aluminum-containing copper-based alloy tube of Example 2 is similar to that of Example 1, except for the ratio of the raw materials.

Embodiment 3

[0039] A copper-based alloy tube containing silicon and aluminum, the mass percentage composition of which is: copper 76%; silicon 0.05%; aluminum 1.8%; the balance is zinc.

[0040] The preparation method of the silicon-and-aluminum-containing copper-based alloy tube of Example 3 is similar to that of Example 1, except for the ratio of the raw materials.

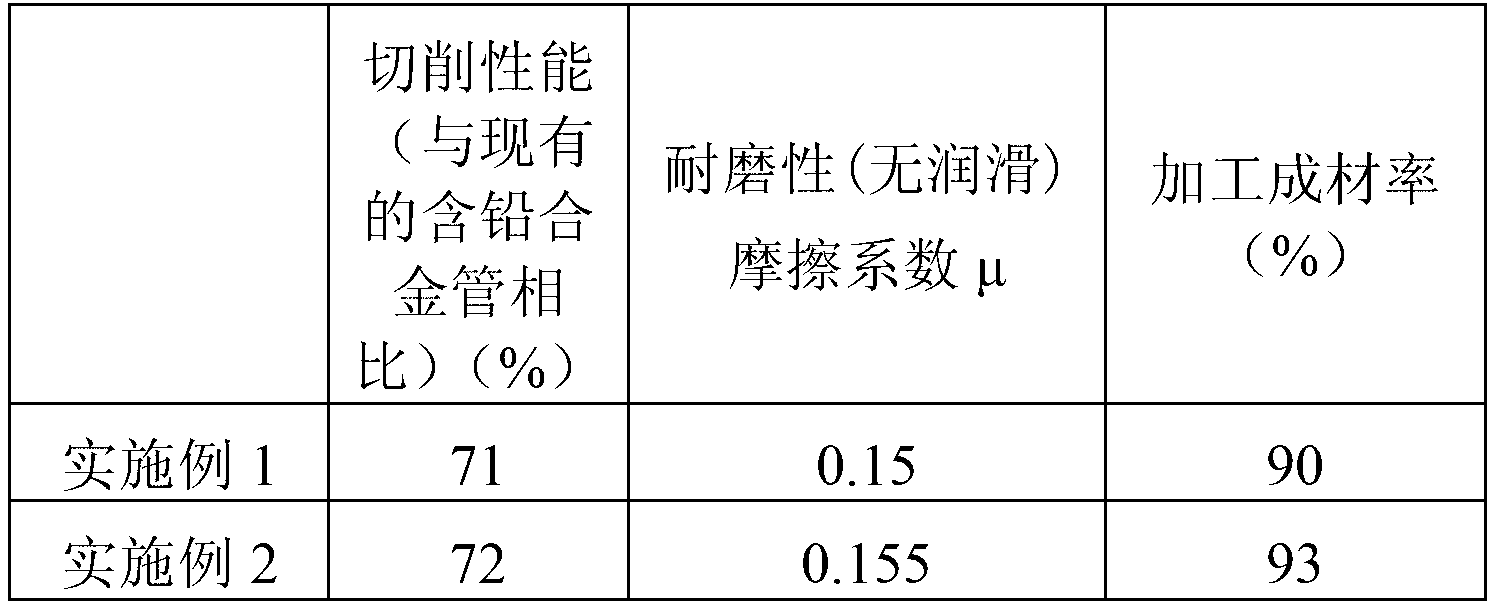

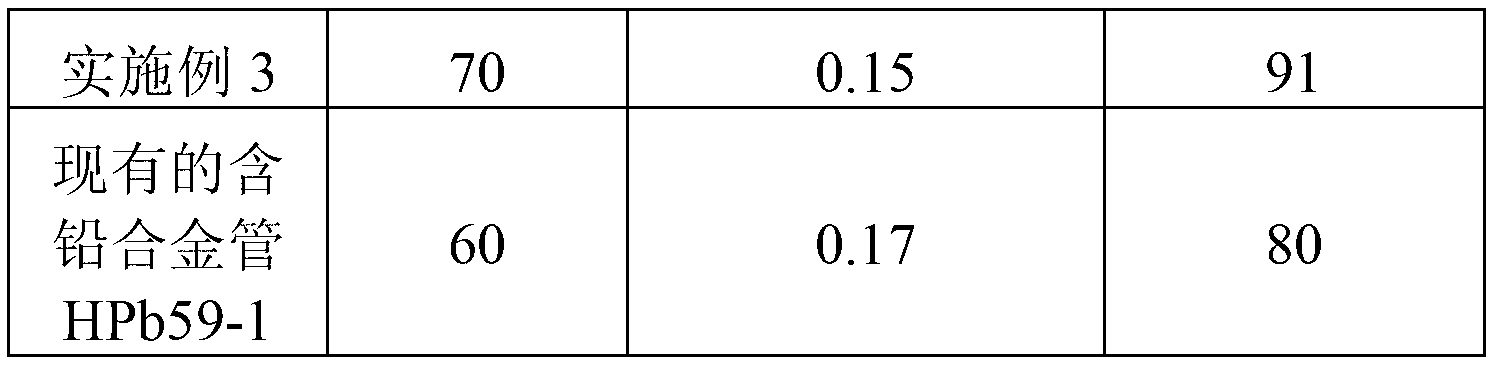

[0041] Table 1 shows the properties of the new lead-free copper alloy materials for welding and the traditional welding materials provided by the present invention.

[0042] Table 1 Performance comparison between copper-based alloy tubes containing silicon and aluminum and lead-tin bronze tubes

[0043]

[0044]

[0045] The copper-based alloy tube containing silicon and aluminum of the present invention maintains or does not significantly reduce the machinability and wear resistance of the original lead-containing tin bronze, eliminates the amount of lead added, and suppresses lead by adding silicon and aluminum elements Dissoluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com