Copper base alloy bar containing silicon and aluminium and preparation method thereof

A technology of copper-based alloy and copper rod, which is applied in the field of copper-based alloy rod containing silicon and aluminum and its preparation, can solve the problems of polluted air, emission of lead dust, harmfulness to human body, etc., and achieve the effect of inhibiting lead dissolution and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

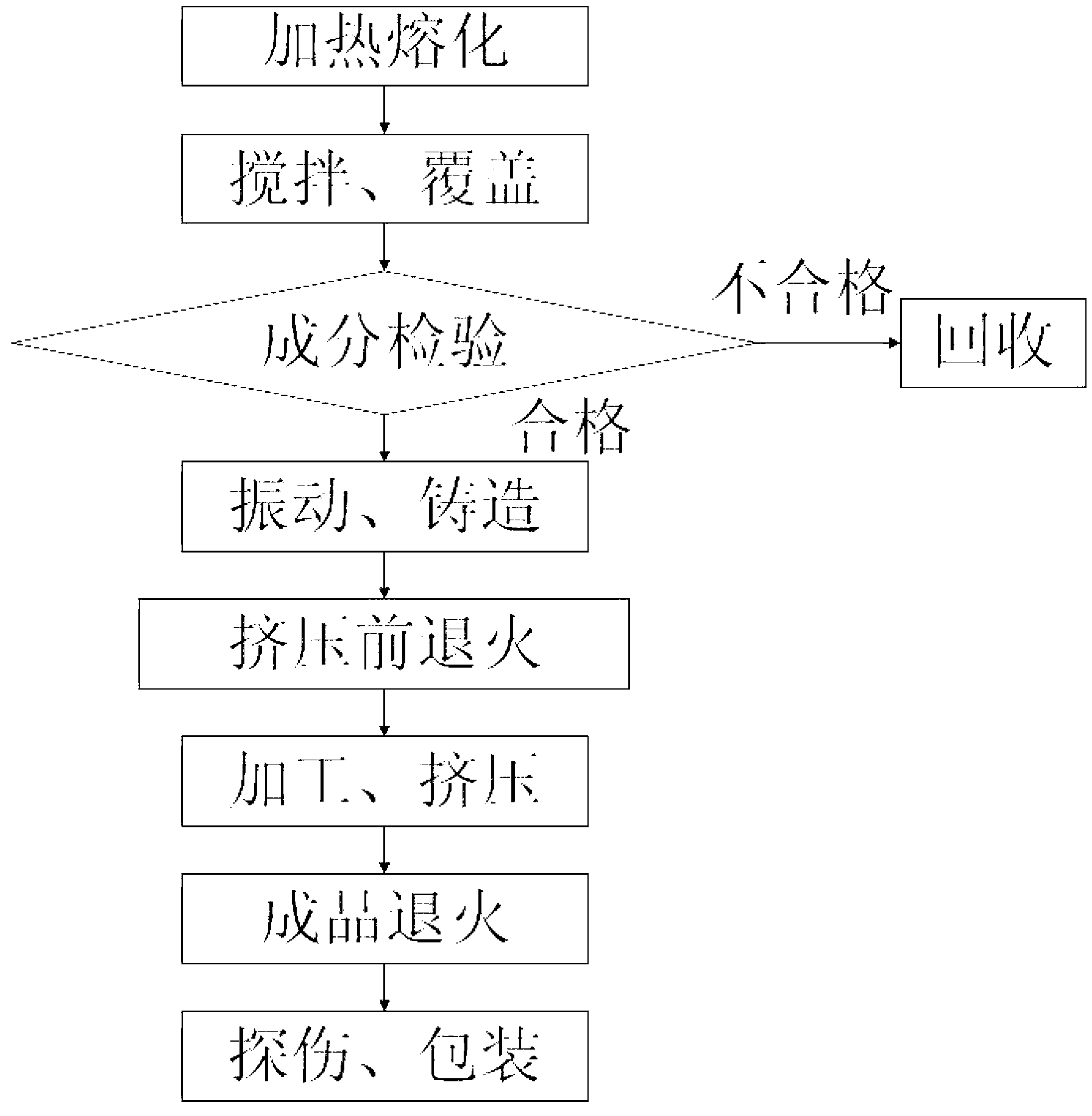

[0026] The preparation method of the copper-based alloy preparation bar of embodiment 1, such as figure 1 shown, including the following steps:

[0027] 1) Place electrolytic copper, silicon, aluminum and zinc in a power frequency electric furnace according to the ratio, heat to 1200-1250 degrees, and keep warm to 1150 degrees after completely melting;

[0028] 2) After fully stirring the completely melted alloy liquid with a graphite rod, cover it with high-purity scaly graphite powder to prevent its oxidation, with a thickness of 10-15cm;

[0029] 3) After 1-1.5 hours of heat preservation, use the German Spike direct-reading spectrometer to conduct 3-6 composition inspections on the samples taken out of the power frequency electric furnace to confirm that the alloy composition is within the specified range;

[0030] 4) After further holding for 1-1.5 hours, heat up to 1200 degrees again, and turn on the vibration device of the power frequency electric furnace, and use the h...

Embodiment 2

[0036] A copper-based alloy rod containing silicon and aluminum, its mass percentage composition is: copper 76%; silicon 0.05%; aluminum 1.8%; the balance is zinc.

[0037] The preparation method of the copper-based alloy rod containing silicon and aluminum in Example 2 is similar to that in Example 1, except that the ratio of raw materials is different.

Embodiment 3

[0039] A copper-based alloy rod containing silicon and aluminum, its mass percentage composition is: copper 76%; silicon 0.05%; aluminum 1.8%; the balance is zinc.

[0040] The preparation method of the copper-based alloy rod containing silicon and aluminum in Example 3 is similar to that in Example 1, the difference lies in the ratio of raw materials.

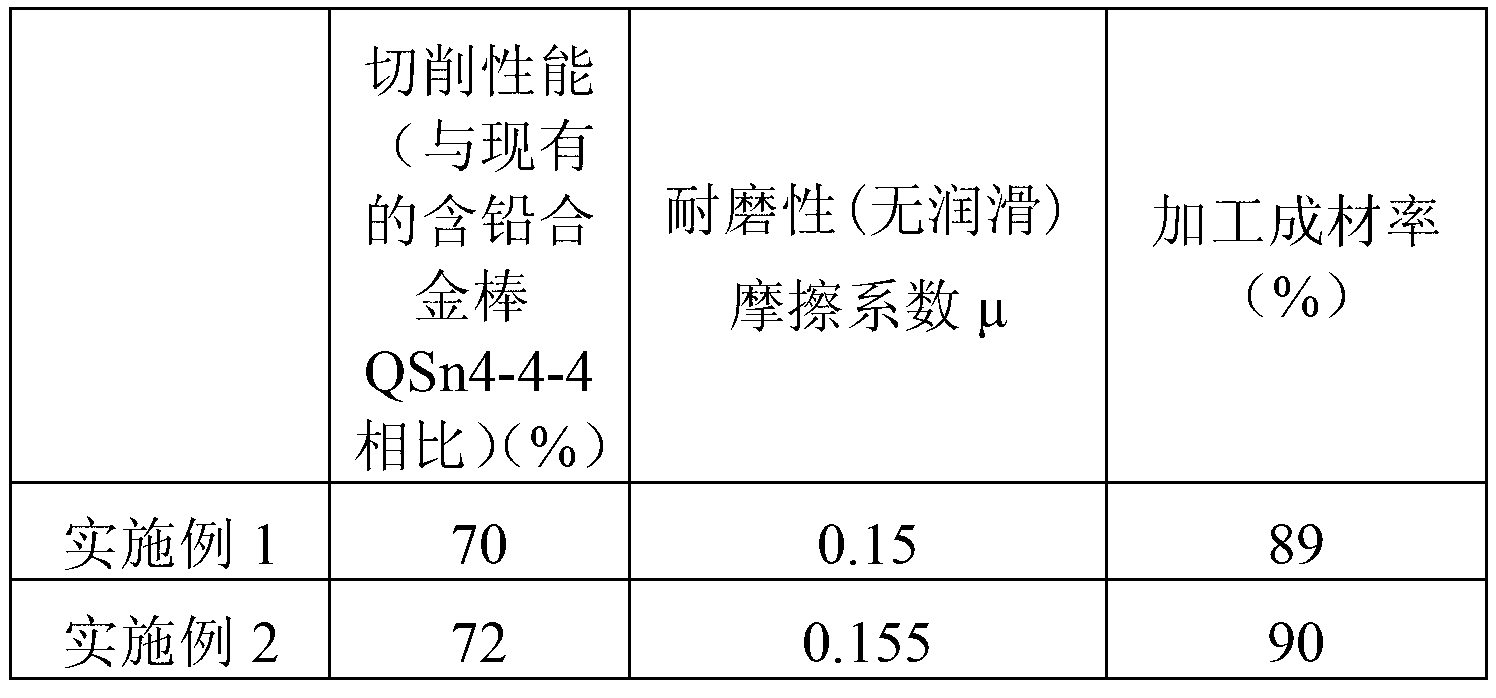

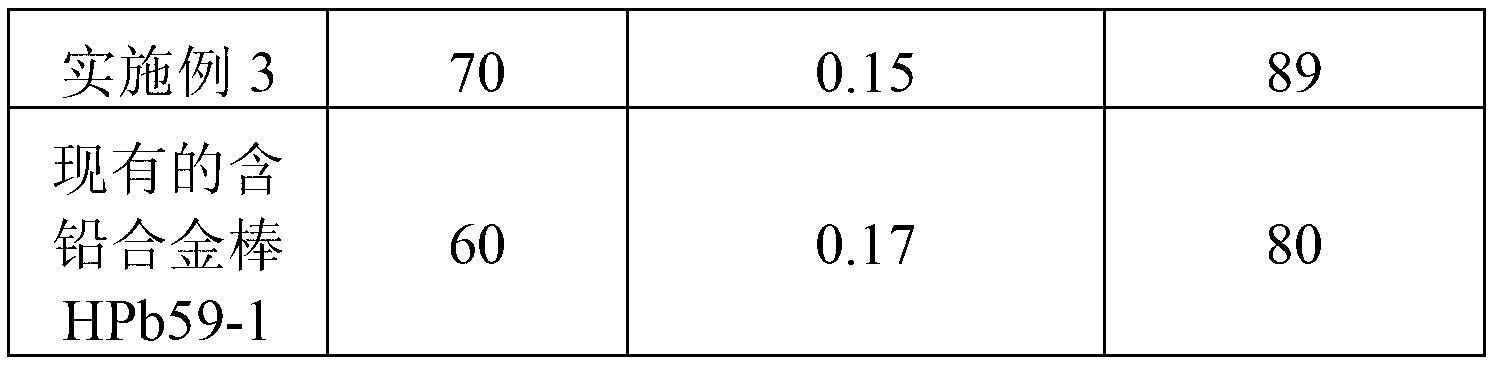

[0041] The properties of the new lead-free copper alloy material used for welding provided by the present invention and the traditional welding material are shown in Table 1.

[0042] Table 1 Comparison of properties between copper-based alloy rods containing silicon and aluminum and lead-containing tin bronze

[0043]

[0044]

[0045] The copper-based alloy rod containing silicon and aluminum of the present invention is based on maintaining or not significantly reducing the machinability and wear-resistance and friction-reducing properties of the original lead-containing tin bronze, eliminating the addition of lead and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com