Brass alloy bar replacing lead element by unidirectionally cutting bismuth, aluminium and tin and preparation for same

A brass alloy, one-way technology, applied in the field of alloy rods, can solve the problems of lead-containing alloy rod pollution, inability to meet requirements, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

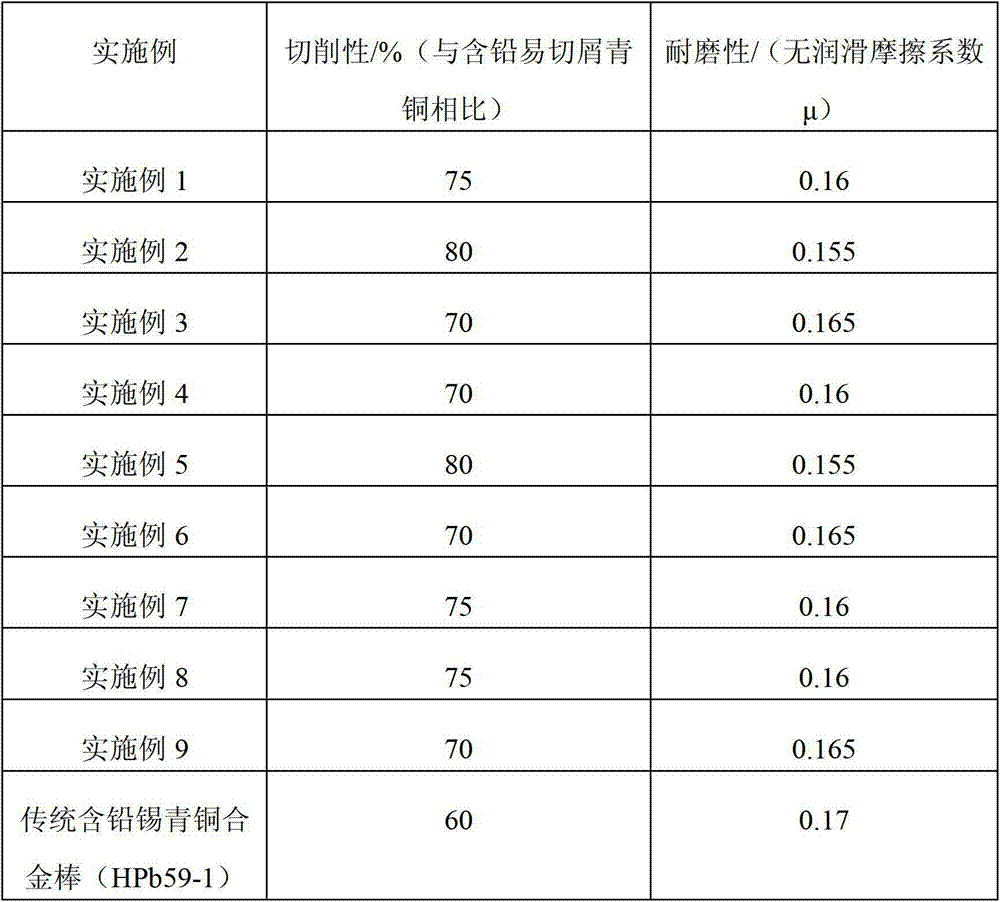

Examples

Embodiment 1

[0023] A brass alloy rod with bismuth, aluminum and tin unidirectional cutting instead of lead, including the following components in weight percentage: 58%-64% copper, 0.5%-3% bismuth, 1%-4% aluminum, 0.5%- 1% tin, the balance zinc.

[0024] The above-mentioned brass alloy rods with bismuth, aluminum and tin unidirectional cutting instead of lead elements can be prepared by the following method: first, put each component in a power frequency electric furnace according to the ratio, heat it to 1200-1280 degrees and completely melt it, then keep it warm to 1230°C-1250°C; After fully stirring the completely melted alloy liquid with a graphite rod, cover it with high-purity scaly graphite powder to prevent its oxidation, the thickness is about 20cm-25cm; after holding time for 1.5h-2.5h, Use the Spike direct-reading spectrometer imported from Germany to conduct 3-5 sub-component inspections on the samples taken out of the furnace, and confirm that the proportion of each element i...

Embodiment 2

[0027] A brass alloy rod with bismuth, aluminum and tin unidirectional cutting instead of lead, including the following components in weight percentage: 58%-63% copper, 1%-3% bismuth, 2%-4% aluminum, 0.5%- 1% tin, the balance zinc.

[0028] The above-mentioned brass alloy rods with bismuth, aluminum and tin unidirectional cutting instead of lead can be prepared by the following method: first, put each component in a power frequency electric furnace according to the ratio, heat it to 1200-1250 degrees and completely melt it, then keep it warm to 1230 degrees; After stirring the completely melted alloy liquid with a graphite rod, cover it with high-purity flake graphite powder to prevent its oxidation, the thickness is about 22cm-25cm; after the holding time is 2h-2.5h, use German imported Si The Parker direct-reading spectrometer conducts 3-5 sub-component inspections on the samples taken out of the furnace, and confirms that the proportion of each element is within the predete...

Embodiment 3

[0031] A brass alloy rod with bismuth, aluminum and tin unidirectionally cut to replace lead, comprising the following components in weight percent: 58% copper, 1% bismuth, 2% aluminum, 0.5% tin, and the balance zinc. The preparation method is as follows:

[0032] Step 1: Put each component in a power frequency electric furnace according to the ratio, heat it to about 1250 degrees, and heat it to about 1240 degrees after it is completely melted; After fully stirring the completely melted alloy liquid with a graphite rod, cover it with high Purity flaky graphite powder to prevent its oxidation, the covering thickness is about 20cm-25cm. After 1.5h-2.5h of heat preservation, the samples taken out of the furnace were inspected for 3-5 times with a direct-reading spectrometer imported from Germany, and the ratio of each element was determined to be within the predetermined range. After further heat preservation for 1h-1.5h, the temperature was raised again to 1250-1280°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com