Wear-resistant nylon composite material and preparation method thereof

A technology of nylon composite materials and wear-resistant materials, which is applied in the field of wear-resistant nylon composite materials and its preparation, and can solve problems affecting the adhesion between wear-resistant modifiers and nylon substrates, high viscosity and density of composite materials, and mechanical properties of composite materials. Influence and other issues, to achieve the effect of reducing the friction coefficient, reducing material wear, and hindering direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

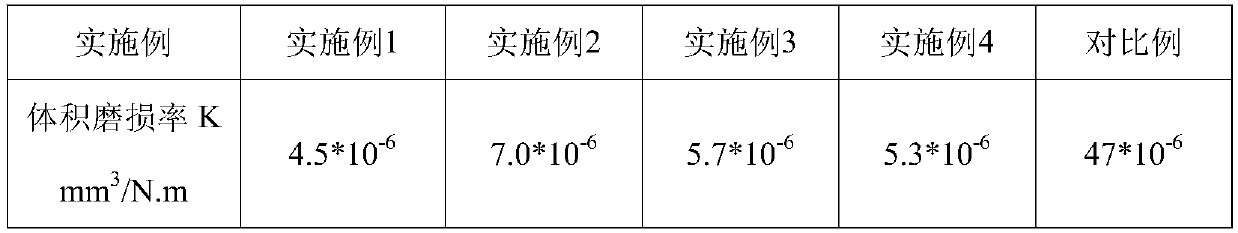

Examples

Embodiment 1

[0027] (1) Put 25 parts of mica powder into a heating furnace at 500°C for heating and calcination for 10 minutes, then heat up to 800°C for 30 minutes; add 6 parts of coupling agent KH550 and stir, then add 4 parts of nano-silicon carbide and 1 part of polytetrafluoroethylene, continue to stir to obtain a wear-resistant material.

[0028] (2) Weigh 79 parts of dry PA-M1013B, 20 parts of wear-resistant material, 0.1 part of antioxidant 1098, 0.1 part of antioxidant 168, and 0.2 part of lubricant EBS according to the weight ratio, and add them to the extruder after mixing , extruded by an extruder, water-cooled and pelletized. Among them, the processing temperature of the extruder is 220°C, 280°C, 290°C, 310°C, 300°C, 305°C from the feeding port to the die port, the main engine speed is 180rpm, and the vacuum degree is -0.03MPa.

Embodiment 2

[0030] (1) Put 15 parts of mica powder into a heating furnace at 600°C for heating and calcination for 5 minutes, then heat up to 900°C for 15 minutes; add 3.6 parts of coupling agent KH550 and stir, then add 2 parts of nano-silicon carbide and 1 part of polytetrafluoroethylene, continue to stir to obtain a wear-resistant material.

[0031] (2) Weigh 89 parts of dry PA-M1013B, 10 parts of wear-resistant material, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, and 0.5 part of lubricant Rico wax E according to the weight ratio, mix and add In the extruder, extruded through the extruder, water-cooled and then pelletized. Among them, the processing temperature of the extruder is 220°C, 280°C, 290°C, 310°C, 300°C, and 305°C from the feeding port to the die port, the main engine speed is 200rpm, and the vacuum degree is -0.05MPa.

Embodiment 3

[0033] (1) Put 40 parts of mica powder into a heating furnace at 500-600 ° C for 5-10 minutes of heating and calcination treatment, then raise the temperature to 800-900 ° C for 15-30 minutes; add 8.8 parts of coupling agent KH550 and stir, Then add 3 parts of nano-silicon carbide and 1 part of polytetrafluoroethylene, and continue stirring to obtain a wear-resistant material.

[0034] (2) Weigh 84 parts of dry PA-Alphalon 27, 15 wear-resistant material, 0.1 part of antioxidant 1098, 0.2 part of antioxidant 168, 0.3 part of lubricant A-C540A according to the weight ratio, mix and add extrusion In the machine, it is extruded by the extruder, cooled by water and cut into pellets. Among them, the processing temperature of the extruder is 220°C, 280°C, 290°C, 310°C, 300°C, and 305°C from the feeding port to the die port, the main engine speed is 350rpm, and the vacuum degree is -0.05MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com