Wear-resistant polypropylene composite material and preparation method thereof

A technology of composite materials and wear-resistant materials, which is applied in the field of wear-resistant polypropylene composite materials and its preparation, can solve the problem of large addition, high viscosity and density of composite materials, and the influence of wear-resistant modifiers on the adhesion of polypropylene matrix And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

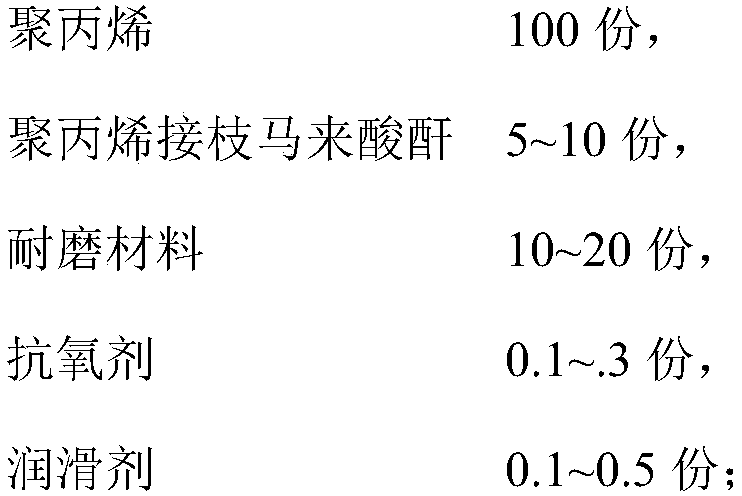

Method used

Image

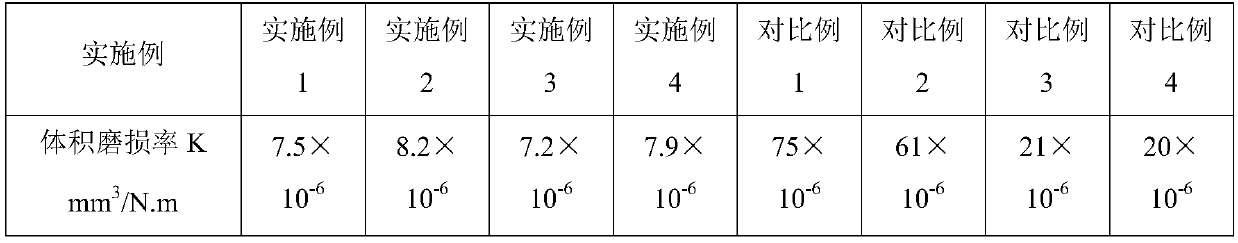

Examples

Embodiment 1

[0021] (1) Heat and calcinate 25 parts of mica powder at 500°C for 10 minutes, then heat up to 800°C for 30 minutes, and cool to room temperature; add 6 parts of coupling agent A-172 and stir evenly, then add 4 parts of nano molybdenum disulfide and 1 part of polytetrafluoroethylene, and continue to stir to obtain a wear-resistant material.

[0022] (2) Weigh 100 parts of dry polypropylene, 5 parts of polypropylene grafted maleic anhydride, 20 parts of wear-resistant material, 0.05 part of antioxidant 1098, 0.05 part of antioxidant 168, and 0.2 part of lubrication by weight. Agent EBS, mixed and added to the extruder, extruded through the extruder, water-cooled and then cut into pellets. Among them, the processing temperature of the extruder is 150°C, 180°C, 190°C, 210°C, 220°C, 220°C from the feeding port to the die port, the main engine speed is 180rpm, and the vacuum degree is -0.03MPa.

Embodiment 2

[0024] (1) Heat and calcinate 15 parts of mica powder at 600°C for 5 minutes, then heat up to 900°C for 15 minutes, and cool to room temperature; add 3.6 parts of coupling agent A-172 and stir evenly, then add 2 parts of nano molybdenum disulfide and 1 part of polytetrafluoroethylene, and continue to stir to obtain a wear-resistant material.

[0025] (2) Weigh 100 parts of dry polypropylene, 10 parts of polypropylene grafted maleic anhydride, 10 parts of wear-resistant material, 0.1 part of antioxidant 1098, 0.1 part of antioxidant 168, and 0.5 part of lubrication by weight. Add white oil to the extruder after mixing, extrude through the extruder, cool with water and cut into pellets. Among them, the processing temperature of the extruder is 150°C, 180°C, 190°C, 200°C, 210°C, and 210°C from the feeding port to the die port, the main engine speed is 200rpm, and the vacuum degree is -0.07MPa.

Embodiment 3

[0027] (1) Heat and calcinate 40 parts of mica powder at 500°C for 10 minutes, then heat up to 800°C for 30 minutes, and cool to room temperature; add 8.8 parts of coupling agent A-172 and stir evenly, then add 3 parts of nano molybdenum disulfide and 1 part of polytetrafluoroethylene, and continue to stir to obtain a wear-resistant material.

[0028] (2) Weigh 100 parts of dry polypropylene, 8 parts of polypropylene grafted maleic anhydride, 15 parts of wear-resistant material, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.1 part of lubrication by weight. Polypropylene wax, mixed and added to the extruder, extruded through the extruder, water-cooled and cut into pellets. Among them, the processing temperature of the extruder is 160°C, 170°C, 180°C, 200°C, 220°C, 220°C from the feeding port to the die port, the main engine speed is 350rpm, and the vacuum degree is -0.05MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com