Bearing outer ring grinding equipment

A bearing outer ring and equipment technology, applied in grinding/polishing equipment, metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem that the bearing outer ring fixing effect is not good enough, affecting product quality and product surface. Carbonization etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

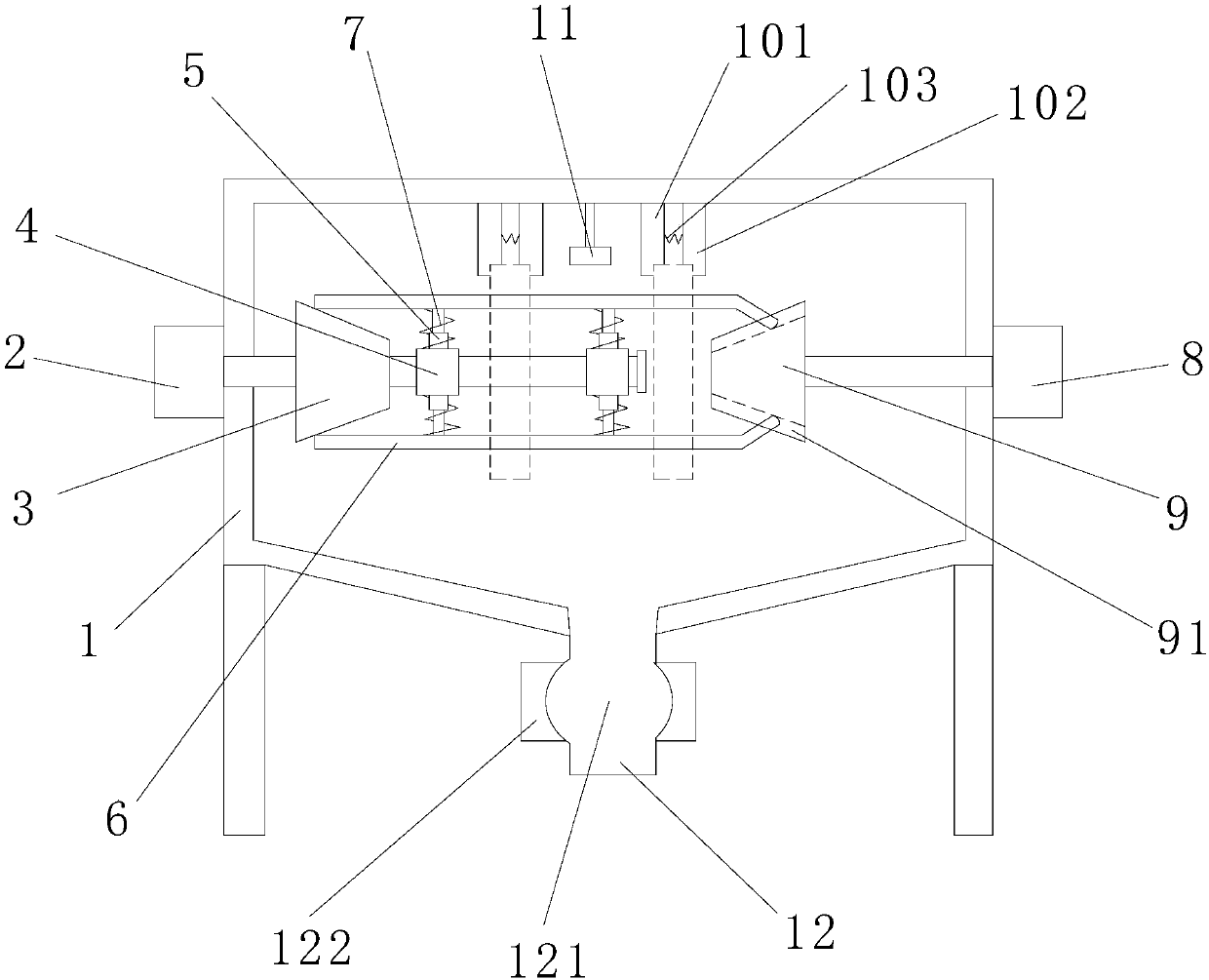

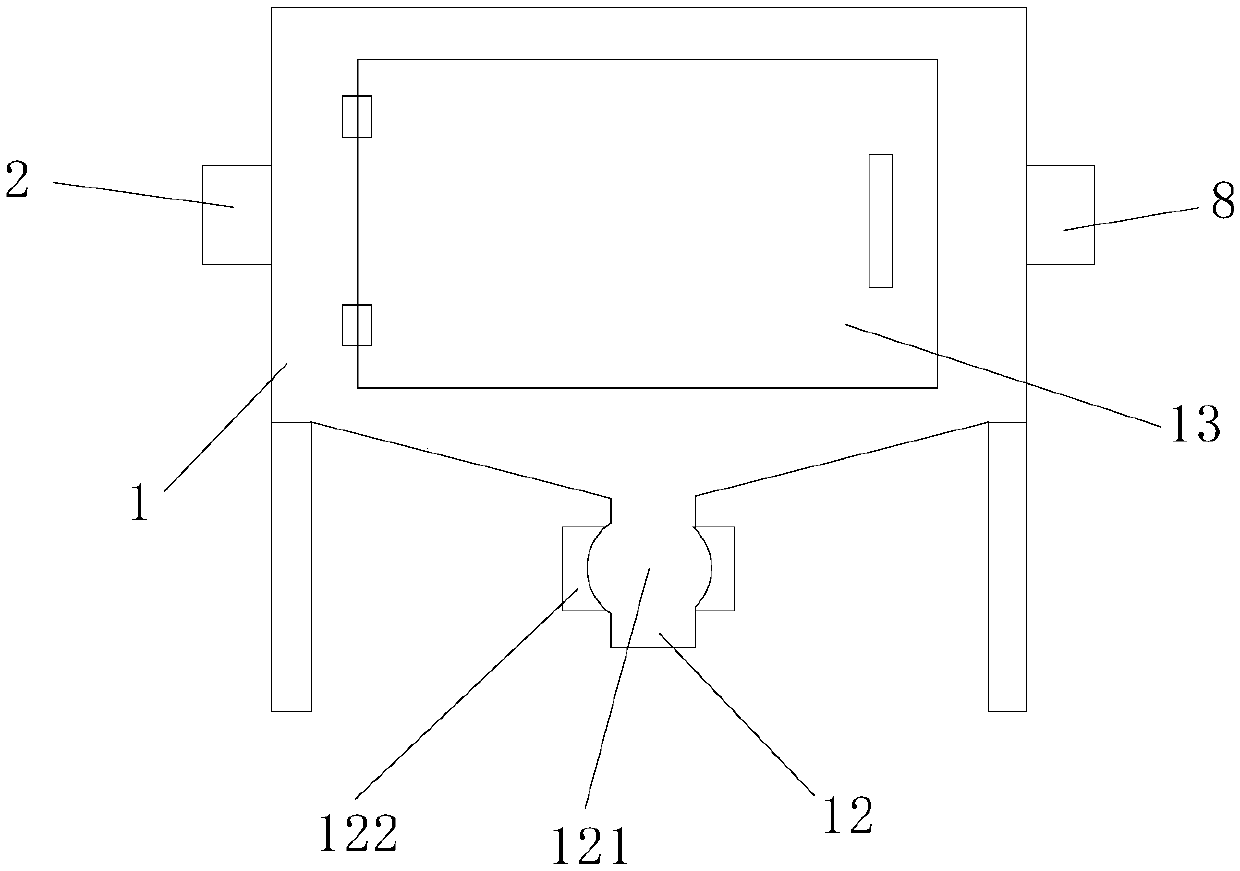

[0018] refer to figure 1 , 2 , a bearing outer ring grinding equipment according to the present invention, comprising a machine cover 1, a motor 2, a block 3, a bushing 4, a telescopic rod 5, a strut 6, a spring 7, a cylinder 8, a stretching block 9, a grinding device 10, Spray nozzle 11 and drain pipe 12, the left side of described hood 1 is fixedly provided with motor 2, and the rotating shaft of described motor 2 extends into the inside of hood 1, and the rotating shaft of described motor 2 is fixedly provided with stopper. Block 3, the block 3 is coaxially arranged with the rotating shaft of the motor 2, and the rotating shaft of the motor 2 is located on the right side of the block 3. A plurality of sleeves 4 are provided on the sliding sleeve, and the side of each of the shaft sleeves 4 All are radially fixed with a plurality of telescopic rods 5 that are evenly arranged, and a plurality of struts 6 are arranged around the rotating shaft of the motor 2, and the struts 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com