Planetary rolling bearing

A rolling bearing and planetary technology, which is applied in the field of planetary rolling bearings, can solve problems such as bearing beam damage, high temperature oil loss, bearing end of service life, etc., to reduce collision friction, reduce high temperature and oil loss time, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

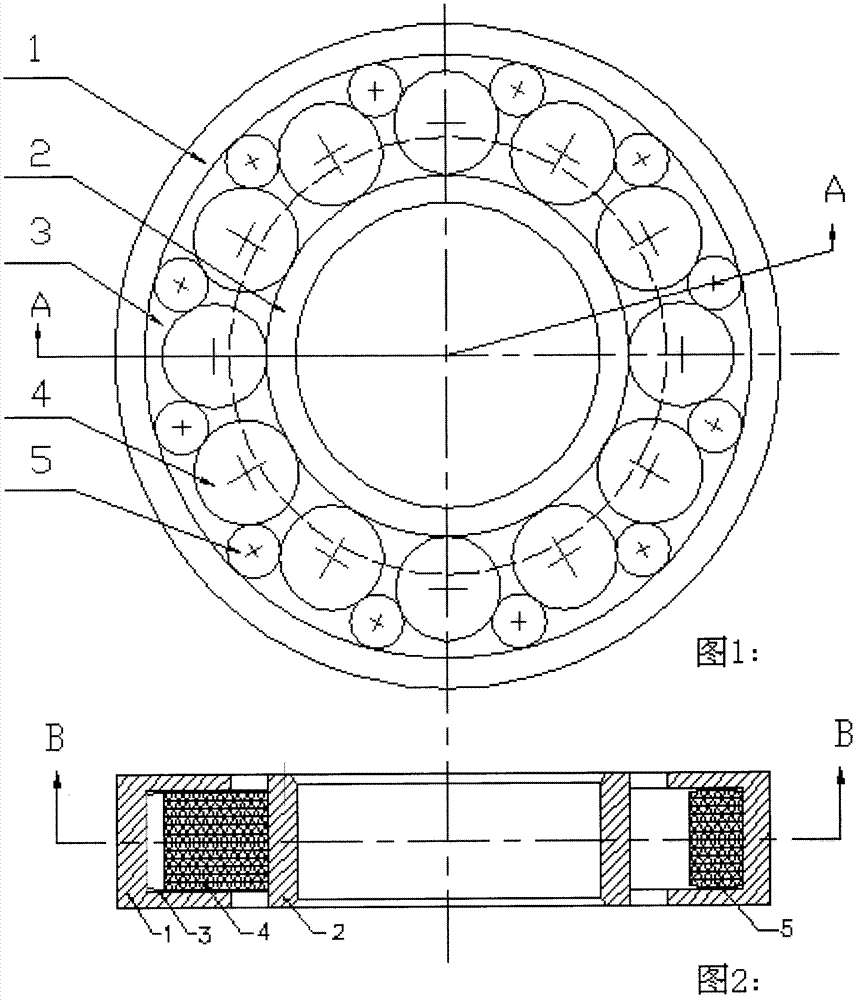

[0012] As shown in Figure 1, the bearing body includes an outer ring 1, an inner ring 2, a raceway 3, a main roller 4, and an auxiliary roller 5; the outer ring 1 and the inner ring 2 are fitted together in a way that the central axis coincides to form a bearing main body bracket; The longitudinal section of the outer ring 1 is U-shaped, which constitutes the upper and lower tops and outer walls of the raceway 3, and the outer side of the inner ring 2 constitutes the inner wall of the raceway 3; the axis of each main roller 4 and two auxiliary rollers 5 The center forms an isosceles triangle to cover the raceway 3. One side of the column body of the main roller 4 is tangent to the outer side of the inner ring 2, that is, the inner wall of the raceway 3, and the other side is tangent to the inner wall of the two auxiliary rollers 5. The column body is ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com