Calcium carbide feeding device for acetylene generator

A technology for acetylene generators and feeding devices, which is applied to acetylene generators, parts of acetylene gas generators, and calcium carbide packaging for generators, etc. It can solve problems such as moisture, explosion, etc., and achieve the effects of preventing accumulation and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

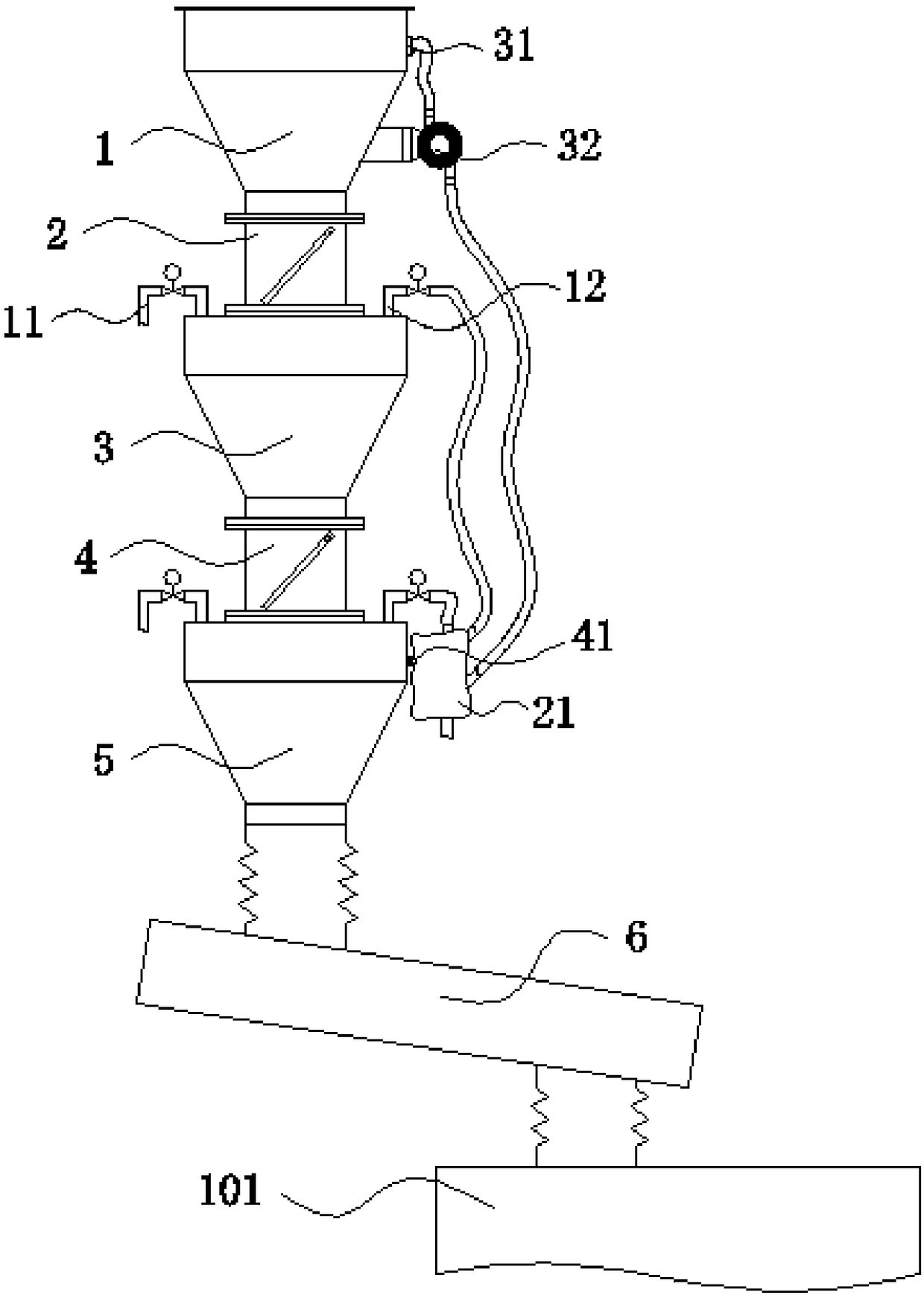

[0014] As shown in the figure: a calcium carbide feeding device for an acetylene generator, including a metering hopper 1, an upper feed valve 2, an upper storage hopper 3, a lower feed valve 4, a lower storage hopper 5 and a vibrating feeder 6; the metering Bucket 1, upper feed valve 2, upper storage bucket 3, lower feed valve 4, and lower storage bucket 5 are sequentially connected through flanges from top to bottom. Connection, the discharge port of the vibrating feeder 6 is connected to the feed port of the acetylene generator 101 through a flexible connection, the metering hopper 1 is provided with a dust discharge port 31 and a suction fan 32, and the dust discharge port 31 and the suction fan 32 The air inlets are connected, the upper storage bucket 3 and the lower storage bucket 5 are respectively provided with a nitrogen filling pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com