Heat-sensitive sensor

A thermal sensor and sensor technology, applied in the field of sensors, can solve the problems of occupying volume, unfavorable efficient combination of batteries, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

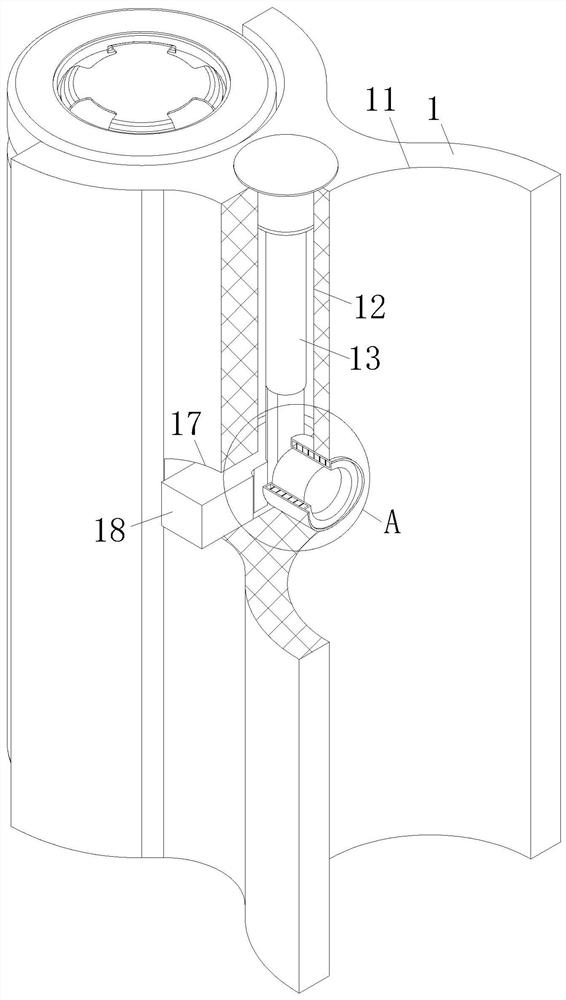

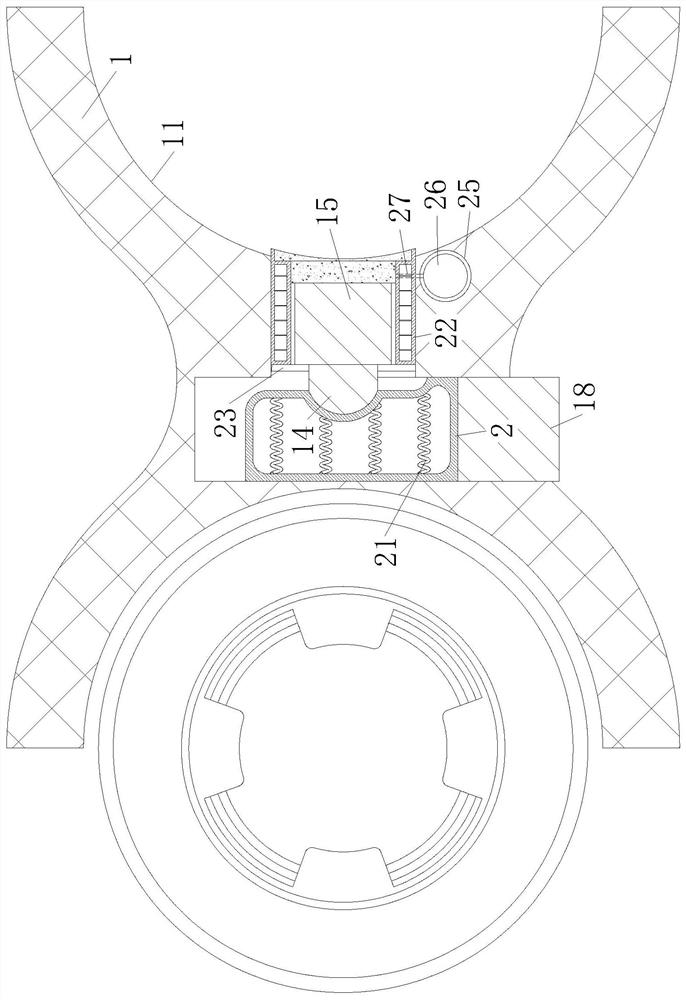

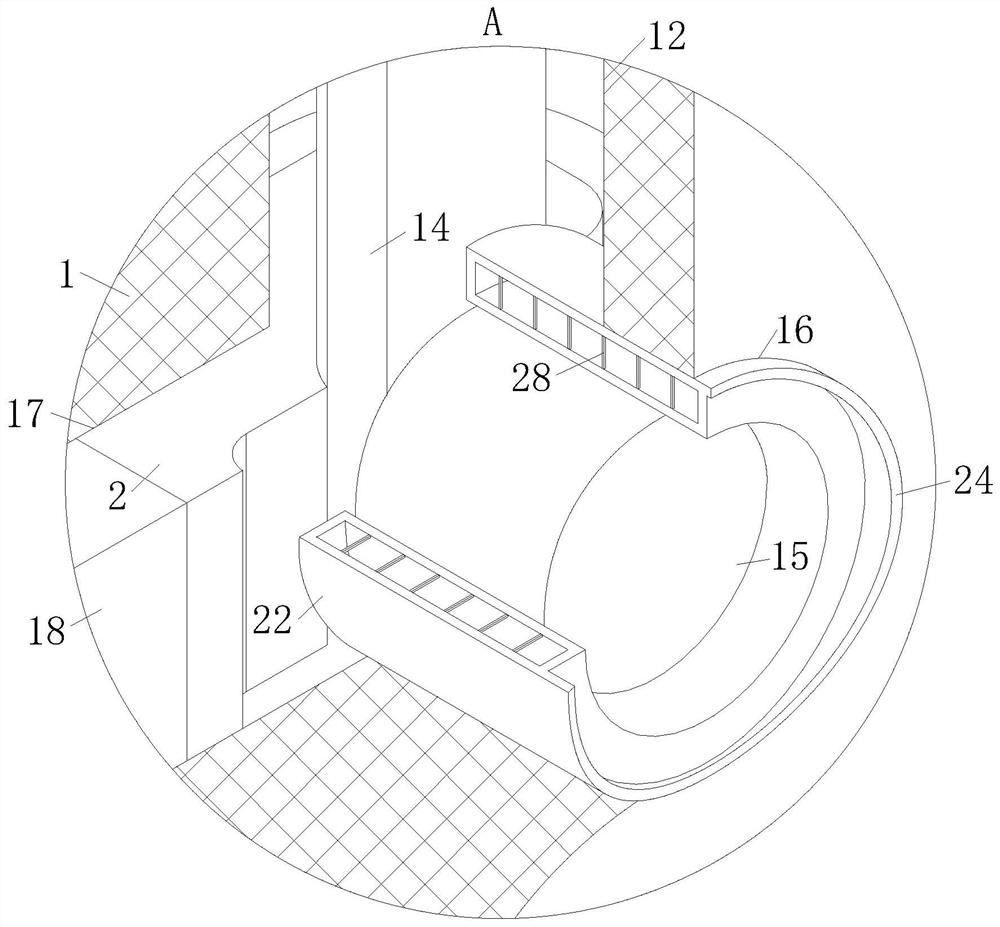

[0022]As an embodiment of the present invention, the bottom of the No. 1 hole 12 is provided with a chute 17 perpendicular to the No. 2 hole 16, and a slider 18 is slidably connected to the chute 17. The slider 18 is close to the bottom of the chute 17. One end is arranged in a wedge shape, and the slider 18 is pressed against the elastic rod 14 to further increase the fit between the probe 15 and the battery cell and increase the detection accuracy of the sensor; when the sensor body 13 is inserted into the No. 1 hole 12, the sensor body 13 drives the elastic The rod 14 and the probe 15 slide down, so that the probe 15 slides down and is embedded in the second hole 16, so that the probe 15 is in contact with the outer wall of the cell clamped in the arc-shaped groove 11, so as to detect the real-time temperature of the cell normally. At the same time, due to the elastic force of the elastic rod 14, the probe 15 is close to the outer wall of the cell, but when the elastic rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com