Preparation method for AlN powder

A technology of powder and aluminum powder, which is applied in the field of AlN powder preparation, can solve the problems of F and Cl ion residues, incomplete nitriding of aluminum powder, and lower production efficiency, so as to achieve large output, reduce crushing time, and improve thermal efficiency. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

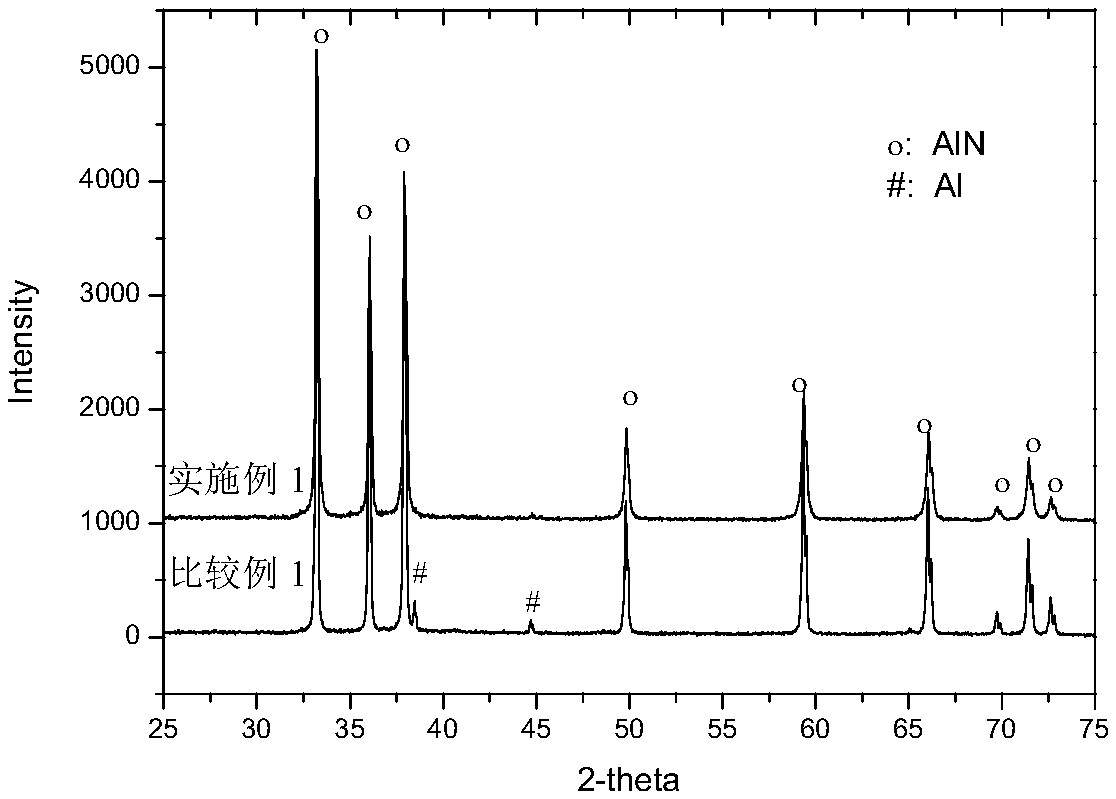

Embodiment 1

[0039] A total of 5 kg of metal Al powder and aluminum nitride powder were mixed uniformly according to the weight ratio of 55:45, and then placed in a porous graphite container, and then placed in a self-propagating reaction synthesis furnace. After closing the furnace and vacuuming to 20Pa, feed the mixed gas of high-purity nitrogen and argon to 4MPa according to the volume ratio of 99:1, and then ignite the ignition agent with electricity to induce the reaction between the metal aluminum powder in the raw material powder and the charged nitrogen , the heat generated by this reaction will ensure that the follow-up reaction continues until all the metal aluminum powder reacts with nitrogen to complete. The composition of the ignition agent is metal Ti powder. The whole synthesis reaction lasted about 10 min, and then cooled to room temperature. After opening the furnace, it was observed that the synthesized aluminum nitride was in the form of an overall soft block, and there...

Embodiment 2

[0041] A total of 5 kg of metal Al powder and aluminum nitride powder were mixed uniformly according to the weight ratio of 60:40, and then placed in a porous graphite container, and then placed in a self-propagating reaction synthesis furnace. After closing the furnace and vacuuming to 20Pa, high-purity argon and high-purity nitrogen are introduced successively according to the volume ratio of 98:2, so that the mixed gas reaches 4MPa, and then the ignition agent is ignited by electricity to induce the metal aluminum powder in the raw material powder and The charged nitrogen reacts, and the heat generated by the reaction will ensure that the subsequent reaction continues until all the metal aluminum powder reacts with nitrogen. The composition of the ignition agent is metal Ti powder. The whole synthesis reaction lasted about 10 min, and then cooled to room temperature. After opening the furnace, it was observed that the synthesized aluminum nitride showed an overall soft blo...

Embodiment 3

[0043] A total of 5 kg of metal Al powder and aluminum nitride powder were mixed uniformly according to the weight ratio of 65:35, and then placed in a porous graphite container, and then placed in a self-propagating reaction synthesis furnace. After closing the furnace and vacuuming to 20Pa, high-purity argon and high-purity nitrogen are introduced successively according to the volume ratio of 95:5, so that the mixed gas reaches 4MPa, and then the ignition agent is ignited by electricity to induce the metal aluminum powder in the raw material powder and The charged nitrogen reacts, and the heat generated by the reaction will ensure that the subsequent reaction continues until all the metal aluminum powder reacts with nitrogen. The composition of the ignition agent is metal Ti powder. The whole synthesis reaction lasted about 10 min, and then cooled to room temperature. After opening the furnace, it was observed that the synthesized aluminum nitride showed an overall soft blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com