Stopper rod for continuous casting of high-oxygen steel

A technology of continuous casting and stopper rods, which is applied in the field of stopper rods for high-oxygen steel continuous casting. It can solve problems such as accelerated stopper rod erosion, molten steel dripping, and large differences in thermal expansion coefficients, so as to improve corrosion resistance and reduce carburization of molten steel. , to maintain the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

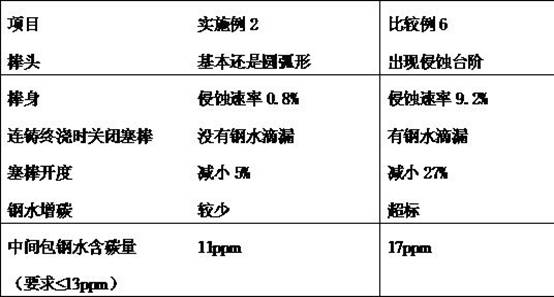

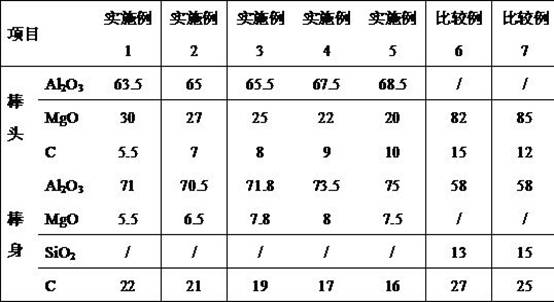

[0016] The present invention will be further described below in conjunction with specific examples.

[0017] A stopper rod for high-oxygen steel continuous casting includes a rod head, a rod body and a slag line section.

[0018] The rod head is made of Spinel-C, and the main raw material includes spinel (Al 2 o 3 -MgO) and graphite (C) materials, the spinel is sintered spinel or fused spinel, and a certain proportion (not more than 10%) of graphite is added, and a small amount of antioxidant (such as metal Al, Si, etc.) and phenolic resin binder. The combination of spinel and graphite makes the material have good thermal shock resistance and excellent erosion resistance, so that the rod head has good flow control performance when casting high oxygen steel, and at the same time reduces the carburization of molten steel. The weight percent of the chemical composition of the rod head is Al 2 o 3 : 60~72%, MgO: 20~30%, C: 5~10%, and the rest are trace impurities.

[0019] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com