Evaporative pattern casting burned shell type casting process

A casting process and lost foam technology, which is applied in the field of lost foam burning shell casting process, can solve the problems of difficulty in guaranteeing precision, variability of castings, large casting defects, etc., and reduce carbon increase of castings, reduce grinding workload, and use The effect of less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

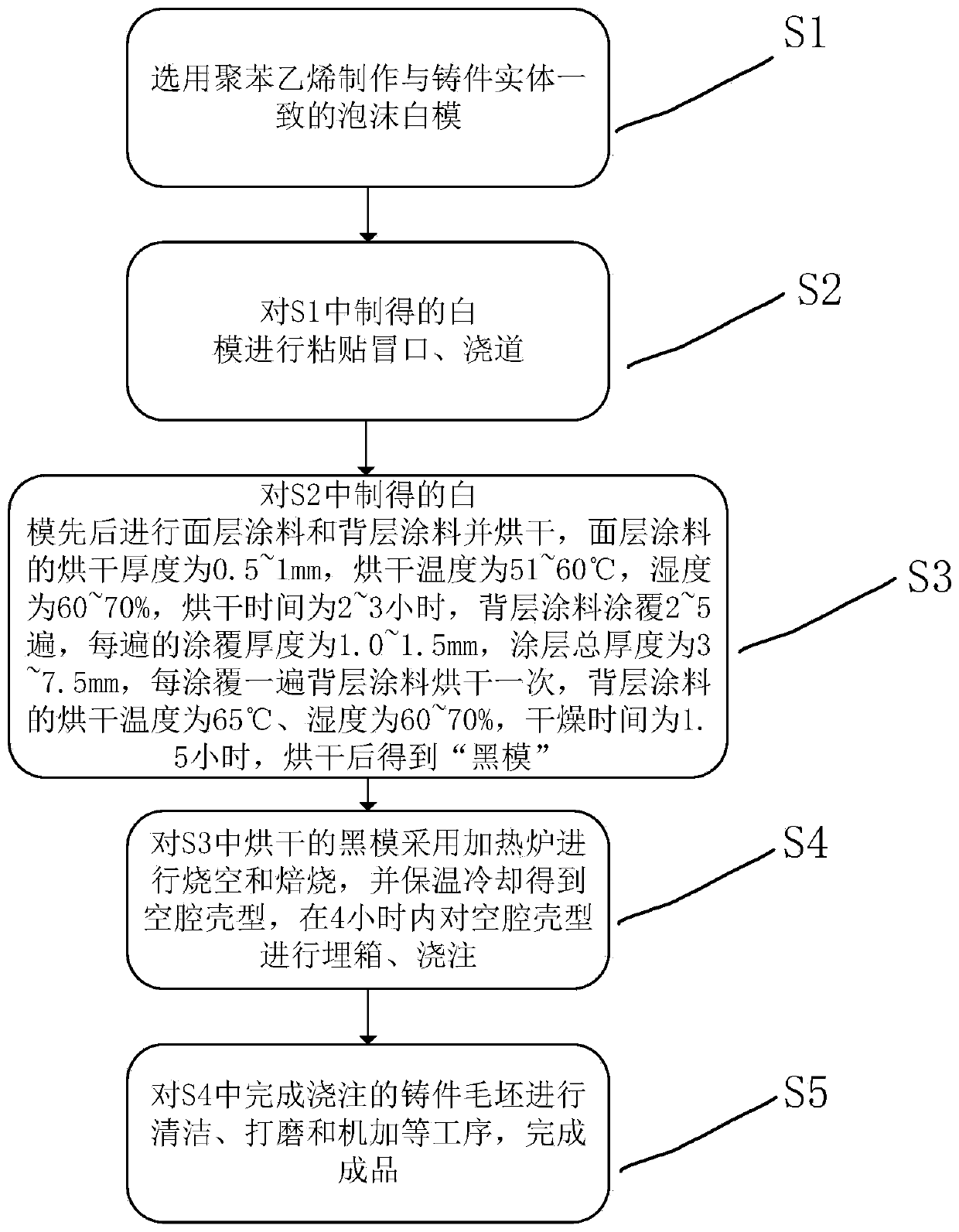

[0024] S1: Use polystyrene to make a white foam mold that is consistent with the casting entity;

[0025] S2: Paste the riser and sprue on the polystyrene foam white mold prepared in S1 according to the process drawing, and reinforce the variable parts, place the white mold on a flat plate or tooling, and use fiber rods, refractory cloth Or ceramic bars and other bonding corrections and reinforcements to prevent deformation;

[0026] S3: The white mold prepared in S2 is successively subjected to surface coating and back coating and drying. Select the corresponding coating according to the requirements of the material and the characteristics of the casting. During the production process of the coating, add powder one after another while stirring the liquid. After mixing, stir quickly for 30 minutes, and store the mixed coating in an environment of 40 ° C. , airtight and must not be exposed to the sun. Before applying the surface coating, it is necessary to ensure that the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com