Method for coating retention around door and window open holes of large ship superstructure

A technology for superstructures and ships, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of grinding quality affecting welding quality, wasting materials, labor costs, and dust construction environment. The effect of improving shipbuilding efficiency and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

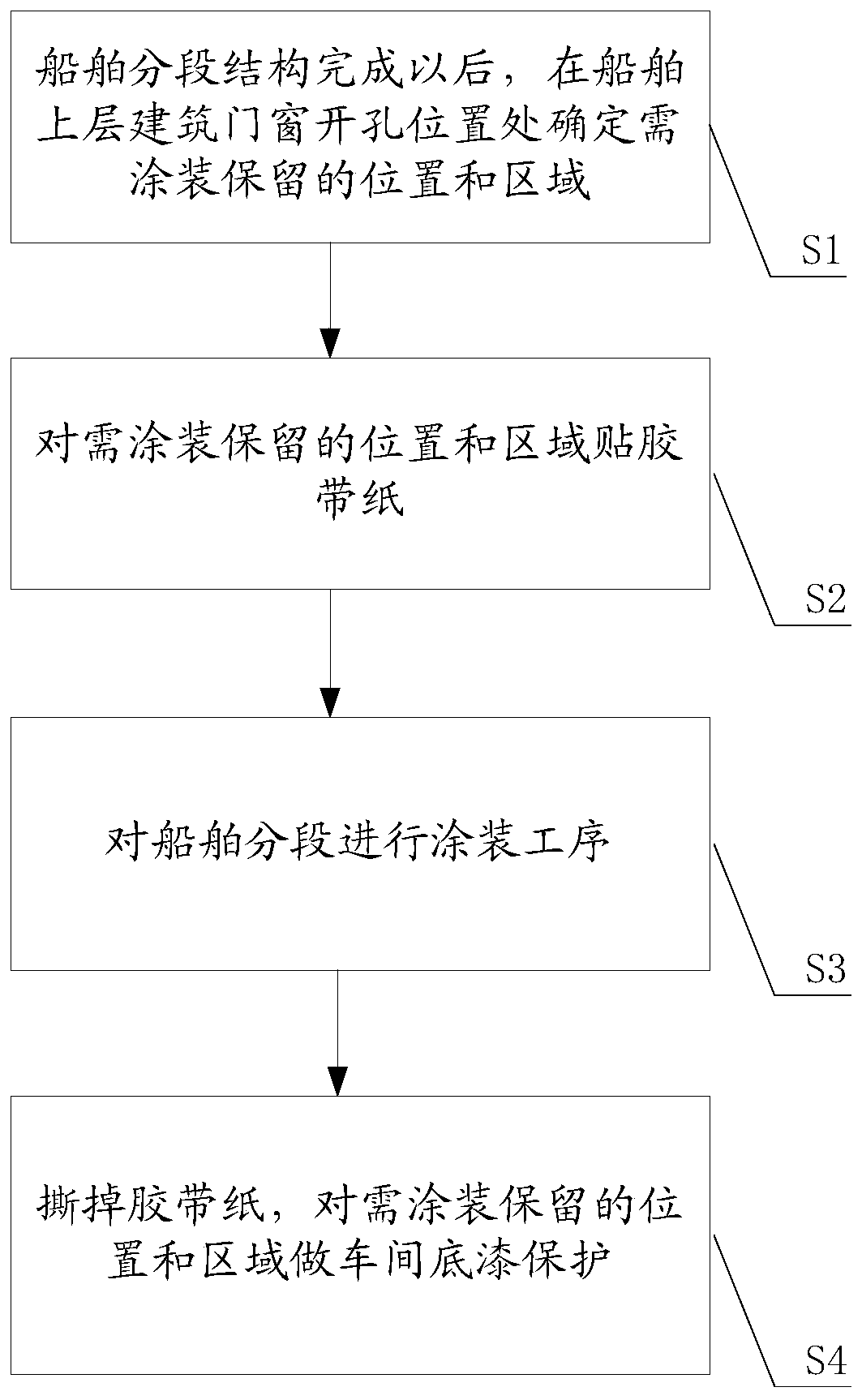

[0020] see figure 1 , the method for painting and retaining around the openings of the doors and windows of the large ship superstructure of the present invention comprises the following steps:

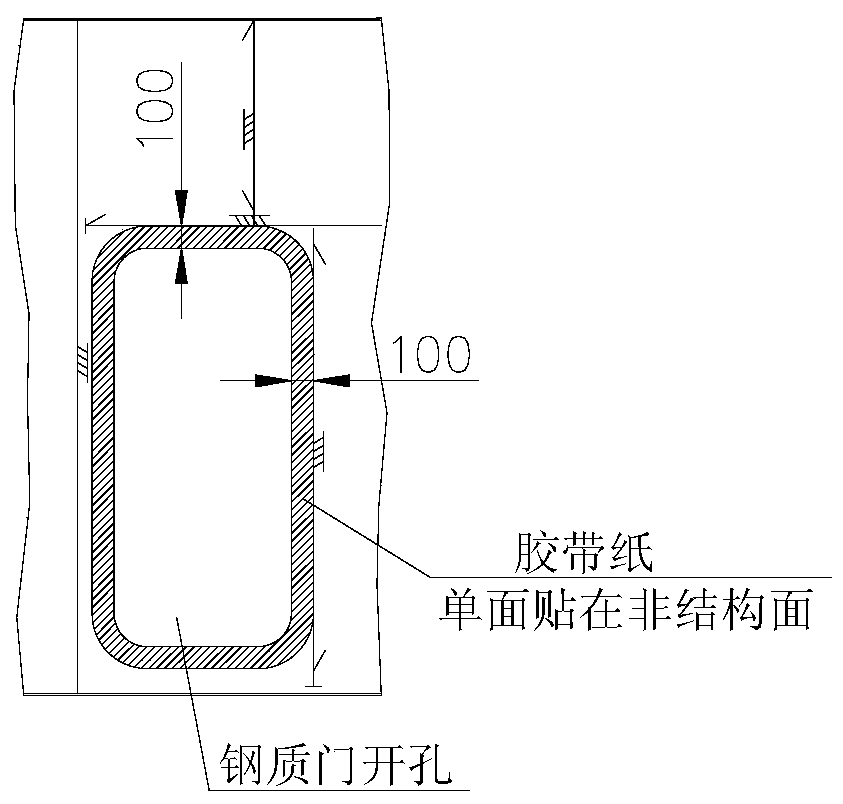

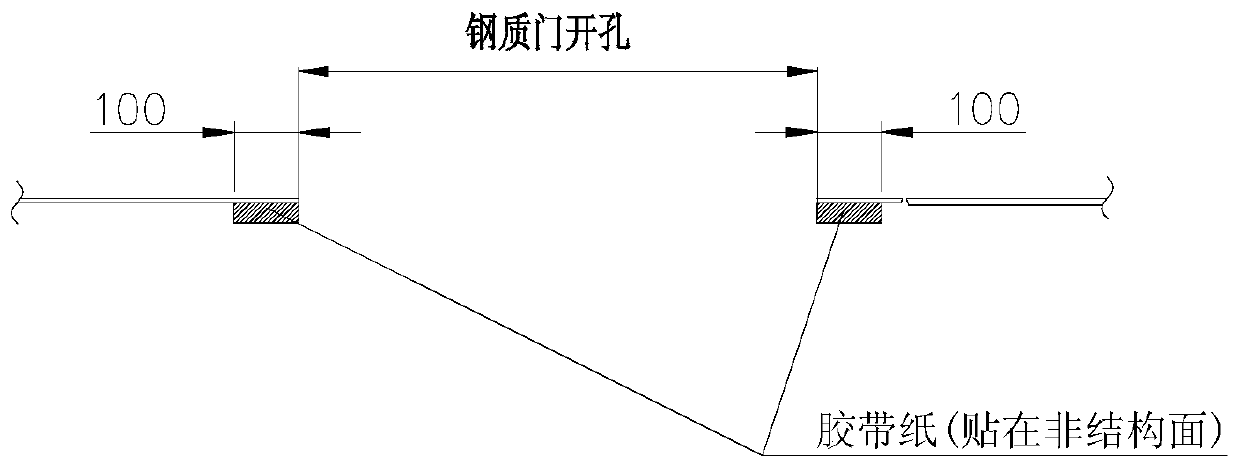

[0021] Step S1, after the completion of the subsection structure of the ship, determine the positions and areas that need to be painted at the opening positions of the doors and windows of the ship's superstructure; specifically, the 100mm range around the single side of the steel door opening is used as the position and areas that need to be painted. area, and one side of the steel door opening is a non-structural side. The 50mm range around both sides of the window opening is used as the position and area to be reserved for painting. Such as Figure 2-Figure 5 shown.

[0022] Step S2, sticking tape on the position and area to be reserved for painting;

[0023] Step S3, perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com