Tundish protection casting method for ultra-low carbon steel

A technology of ultra-low carbon steel and casting method, which is applied in the field of tundish protection and casting of ultra-low carbon steel, can solve the problems of increasing cost and difficulty, and achieves reduction of smelting difficulty, smelting cost and cycle, and reduction of carbon removal pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

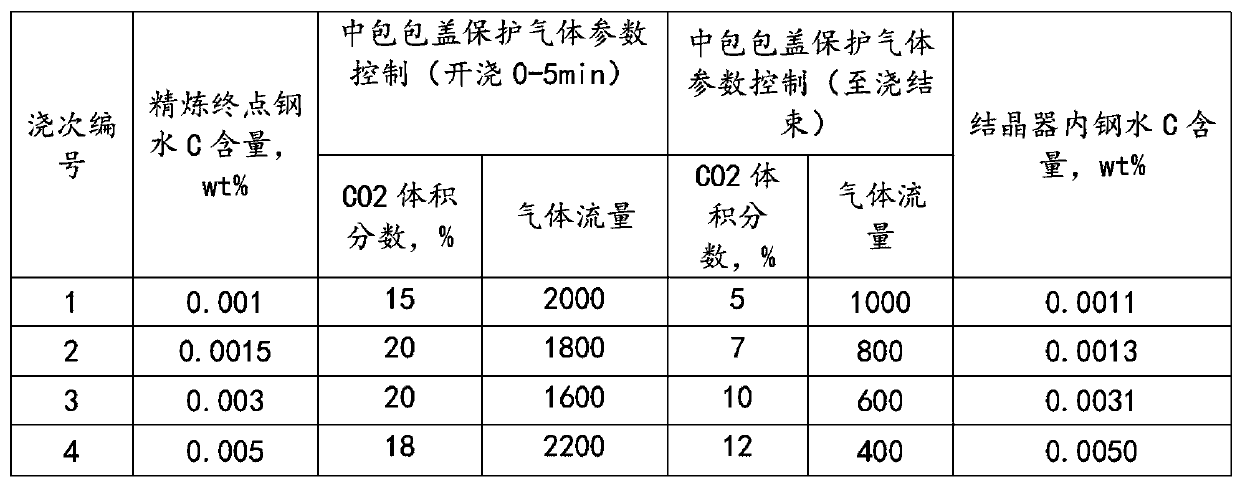

Examples

Embodiment 1

[0027] A tundish protective casting method for ultra-low carbon steel, comprising the following steps:

[0028] S1, ultra-low carbon steel casting, when casting, the tundish cover blowing device blows out the mixed gas of carbon dioxide and argon; the mass fraction of C element of ultra-low carbon steel is 0.01%; cover the cover in full argon On the basis of the shielding gas flow, it is also necessary to consider that each unit volume of carbon dioxide gas will produce two units of CO gas, resulting in an increase in gas flow. The CO gas is detected once every 5 minutes by the CO detector, and recorded for comparison to judge the rising trend of the CO gas concentration.

[0029] At the casting temperature T, the formula is:

[0030] C+CO 2 (g)→2CO 2 (g)ΔG=144700-1295T

[0031] In the formula, C is the carbon content in ultra-low carbon steel, CO 2 is the mass of carbon dioxide, ΔG is a constant -2.18×10 6 ;

[0032] When the casting temperature is 1600℃, the reaction ...

Embodiment 2

[0037] A tundish protective casting method for ultra-low carbon steel, comprising the following steps:

[0038] S1. Casting of ultra-low carbon steel. When casting, the tundish cover blowing device blows out the mixed gas of carbon dioxide and argon; the mass fraction of C element in the steel grade of ultra-low carbon steel is 0.001%; the cover is covered in full argon On the basis of the shielding gas flow, it is also necessary to consider that each unit volume of carbon dioxide gas will produce two units of CO gas, resulting in an increase in gas flow. The CO gas is detected once every 10 minutes by the CO detector, and recorded for comparison to judge the rising trend of the CO gas concentration.

[0039] At the casting temperature T, the formula is:

[0040] C+CO 2 (g)→2CO 2 (g)ΔG=144700-1295T

[0041] In the formula, C is the carbon content in ultra-low carbon steel, CO 2 is the mass of carbon dioxide, ΔG is a constant -2.18×10 6 ;

[0042] When the casting temp...

Embodiment 3

[0047] A tundish protective casting method for ultra-low carbon steel, comprising the following steps:

[0048] S1. Casting of ultra-low carbon steel. During casting, the tundish cover blowing device blows out a mixture of carbon dioxide and argon; On the basis of the shielding gas flow, it is also necessary to consider that each unit volume of carbon dioxide gas will produce two units of CO gas, resulting in an increase in gas flow. The CO gas is detected once every 6 minutes by the CO detector, and recorded for comparison to judge the rising trend of the CO gas concentration.

[0049] At the casting temperature T, the formula is:

[0050] C+CO 2 (g)→2CO 2 (g)ΔG=144700-1295T

[0051] In the formula, C is the carbon content in ultra-low carbon steel, CO 2 is the mass of carbon dioxide, ΔG is a constant -2.18×10 6 ;

[0052] When the casting temperature is 1630℃, the reaction ΔG=-2.18×10 6 , and with the elimination of product CO, the reaction can continue to proceed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com