A kind of biomedical tinb base titanium alloy and preparation method thereof

A biomedical, base titanium alloy technology, applied in the field of biomedical titanium alloys, can solve the problems of easy oxidation of titanium alloys, increase preparation costs, element segregation, etc., achieve important theoretical significance and engineering value, reduce preparation costs, and reduce smelting. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of biomedical TiNb-based titanium alloy, comprising the following steps:

[0026] S1: According to the composition ratio of 31-39wt% Nb, 0.4-0.8wt% O, and the balance being Ti, the ingot or alloy ingot of each metal element of the titanium alloy is mixed with TiO 2 Powder, ultrasonically cleaned and pickled to remove surface impurities, and then smelted in a vacuum non-consumable electric arc furnace to prepare titanium alloy ingots;

[0027] S2: Homogenize the titanium alloy ingot prepared in step S1 at 1000-1100° C. for more than 2 hours, and then perform hot forging and rolling at 650-750° C. to obtain a titanium alloy plate or bar;

[0028] S3: The titanium alloy plate or rod obtained in step S2 is subjected to solution treatment at (500-600)+650[O]°C, protected by an argon atmosphere, and water-cooled to obtain the final titanium alloy, wherein [O] is oxygen mass percent.

[0029] Through a method for preparing a biomedical TiNb-based titaniu...

Embodiment 1

[0033] Embodiment 1: Preparation of Ti-38Nb-0.6O alloy

[0034] (1) Prepare high-purity Ti ingot, Nb ingot, TiO 2 Powder raw materials, and according to the composition ratio of 38wt% Nb, 0.6wt% O, and the balance of Ti, the raw materials are subjected to steps such as ultrasonic cleaning and pickling to remove surface impurities. The raw materials are melted in a vacuum non-consumable electric arc furnace, and melted into TiNbO ingots;

[0035] (2) The above-mentioned TiNbO ingot was homogenized at 1100°C for 2 hours, and then hot forged at 750°C to obtain an alloy plate.

[0036] (3) The above-mentioned alloy plate is subjected to solution treatment at 900° C. and cooled with water.

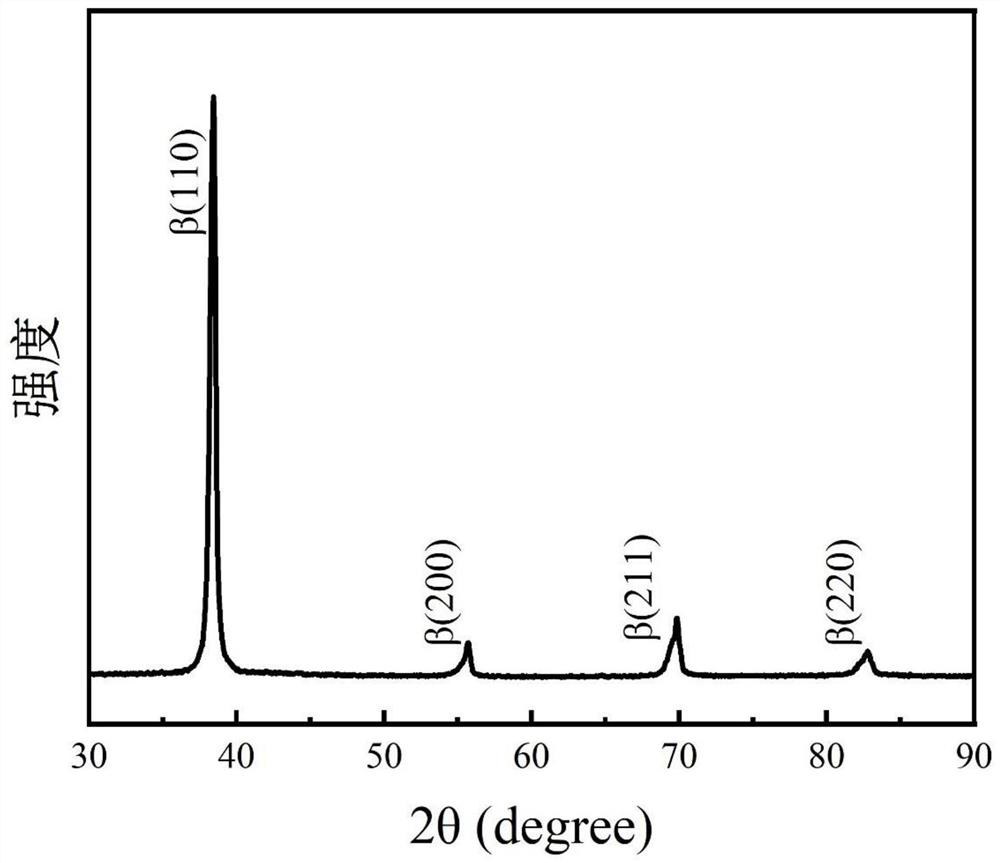

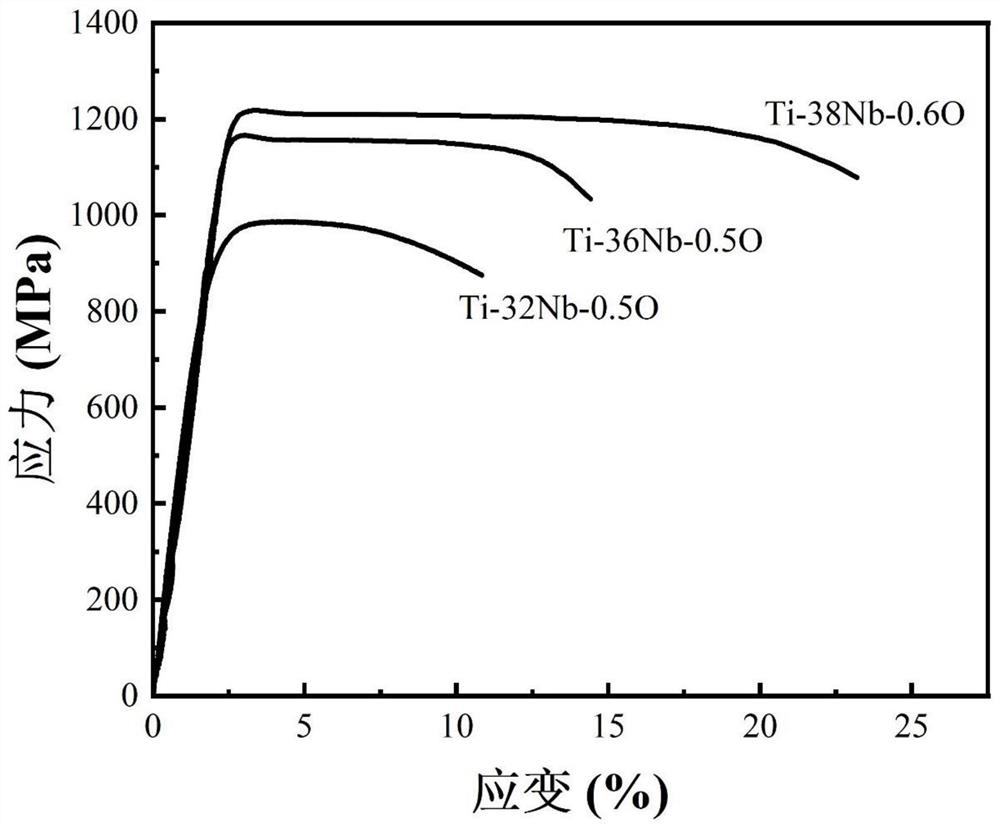

[0037] The Ti-38Nb-0.6O alloy prepared in this implementation is a single β phase, such as figure 1 Shown in the XRD pattern of. Pass the tensile test ( image 3 ), the modulus of elasticity of the titanium alloy is 52GPa, the tensile strength is 1210MPa, and the elongation is 22%.

Embodiment 2

[0038] Embodiment 2: Preparation of Ti-36Nb-0.5O alloy

[0039] (1) Prepare high-purity Ti ingot, Nb ingot, TiO 2Powder raw materials, and according to the ratio of 36wt% Nb, 0.5wt% O, and the balance of Ti, ultrasonic cleaning, pickling and other steps are carried out to remove surface impurities. The raw materials are put into a vacuum non-consumable electric arc furnace for smelting, and smelted into TiNbO ingots.

[0040] (2) Homogenize the above ingot at 1100°C for 2 hours, and then perform hot forging at 750°C to obtain an alloy plate;

[0041] (3) The above-mentioned alloy plate is subjected to solution treatment at 830° C. and cooled with water.

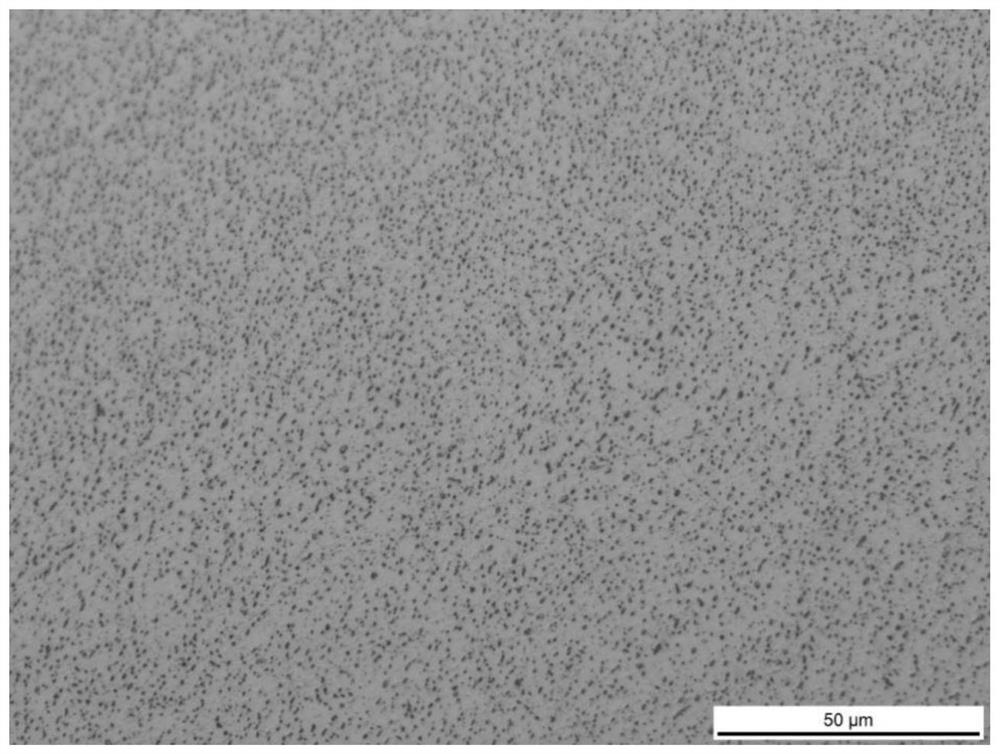

[0042] The structure of the Ti-36Nb-0.5O alloy prepared in this implementation is α+β two phases, wherein the α phase is spherical and the content is 10%. Pass the tensile test ( image 3 ), the modulus of elasticity of the titanium alloy is 60GPa, the tensile strength is 1160MPa, and the elongation is 16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com