Castable for working layer of refining ladle slag line as well as preparation method and application of castable

A technology of castables and slag cladding lines, which is applied in the field of refractory materials to achieve the effects of strong integrity, reduced consumption of refractory materials, and shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

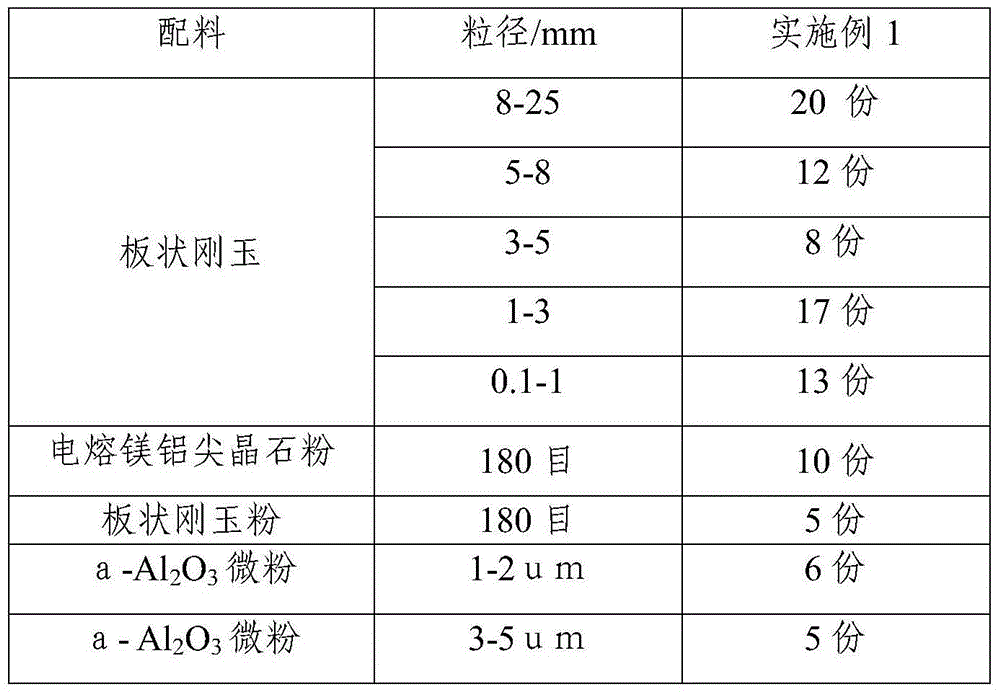

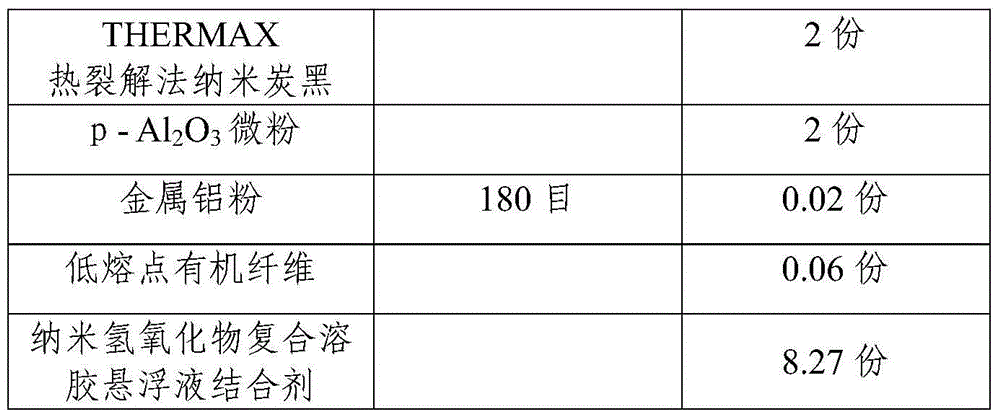

[0048] In this embodiment, the batching of the castable for the working layer of the refining ladle slag line includes the following components:

[0049]

[0050]

[0051] Among them, the batching of 8.27 parts of nano hydroxide composite sol suspension binder includes 2 parts of nano aluminum hydroxide, 2 parts of nano magnesium hydroxide, 0.15 part of sodium hexametaphosphate, 0.10 part of sodium tripolyphosphate, 0.02 part of citric acid, 4 parts water.

Embodiment 2

[0053] In this example, the ingredients given in Example 1 are used to prepare the castable for the working layer of the refining ladle slag line. The preparation method includes the following steps:

[0054] (1) according to the batching preparation 500kg raw material of the nano-hydroxide composite sol suspension binding agent that provides in embodiment 1, this raw material was stirred in GW750 mixer for 8 hours, made nano-hydroxide sol suspension binding agent; respectively Sealed and packaged for use.

[0055] (2) Aggregate and matrix powder are prepared 1000.8kg of raw materials according to the batching given in Example 1, and the above raw materials are dry-mixed in a GW750 mixer for 3-5 minutes to obtain a mixture; Materials, sealed and packaged separately for use.

[0056] (3) Join the prepared nano hydroxide sol suspension binder in step (1) according to the ratio of embodiment 1 in the mixture obtained in step (2), and continue to wet mix and stir in the GW750 mix...

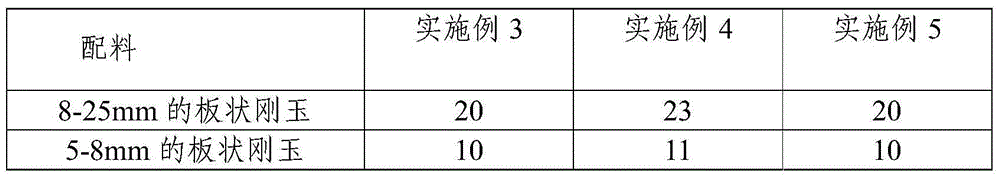

Embodiment 3-5

[0058] Compared with Example 1, the only difference is that the ingredients of the castable for the working layer of the refining ladle slag line in Examples 3-5 are composed of the following raw materials, as shown in the following table:

[0059]

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com