Phenolic resin containing nano-carbon powder, nano-carbon modified low carbon magnesium carbon brick and production method thereof

A nanometer carbon powder and phenolic resin technology, applied in the field of low carbon magnesia carbon bricks and preparation, can solve the problems of unintroduced performance indicators and low thermal conductivity, and achieve the effects of improving anti-peeling performance, low carbon content and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

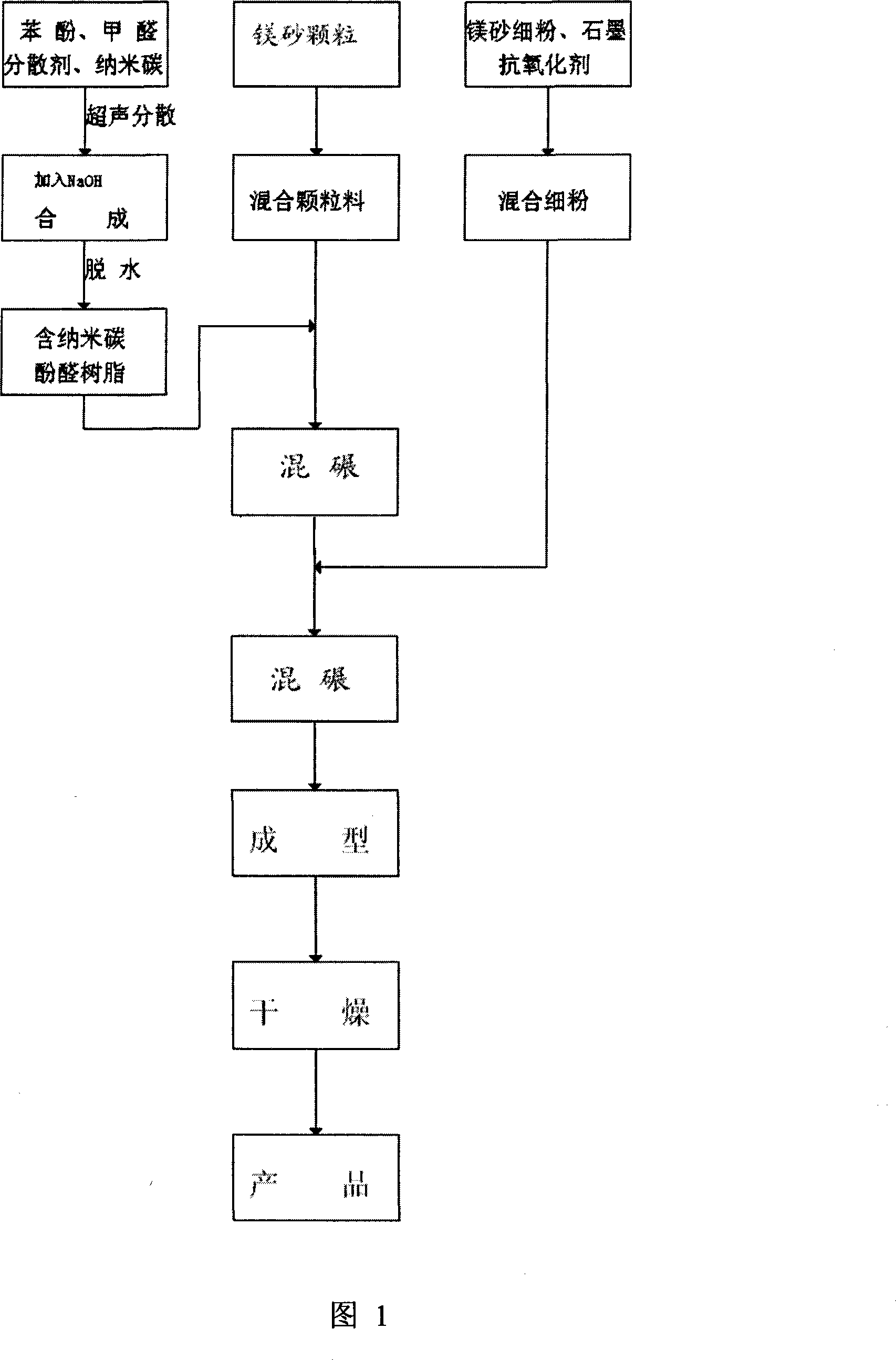

[0032]Embodiment 1, the preparation that contains nano-carbon powder phenolic resin and nano-carbon modified low-carbon magnesia-carbon brick

[0033] 1. Preparation of phenolic resin

[0034] (1) 100 parts by weight of phenol, 112.5 parts by weight of 37% formaldehyde solution and 1.5 parts by weight of polyethylene glycol octylphenyl ether are added to the reaction kettle together, and 20 parts by weight of 30nm average particle diameter are slowly added while stirring. Nano carbon black, disperse for 40 minutes under the action of ultrasonic waves, then keep warm at 40°C and stir for 60 minutes;

[0035] (2) Add 1.0 parts by weight of catalyst NaOH, adjust the pH value to 9, control the temperature to 105°C and keep it warm for 3.0h, and stop the reaction;

[0036] (3) Vacuum dehydration under reduced pressure for 4.0 hours until the viscosity is 5.0 Pa·s, then cooling and discharging to obtain a phenolic resin binder containing nano-carbon black.

[0037] 2. Preparation ...

Embodiment 2

[0044] Example 2: Preparation of phenolic resin containing nano-carbon powder and nano-carbon modified low-carbon magnesia-carbon brick

[0045] 1. Preparation of phenolic resin

[0046] (1) 100 parts by weight of phenol, 120 parts by weight of 37% formaldehyde solution and 1.5 parts by weight of polyvinylpyrrolidone are added together in the reactor, slowly adding 45 parts by weight of nano-graphite with an average particle diameter of 60nm while stirring. Disperse under action for 50 minutes, then keep warm at 60°C and stir for 30 minutes;

[0047] (2) Add 2.0 parts by weight of NaOH, adjust the pH value to 8.5, control the temperature to 100° C. and keep it warm for 2.0 hours to stop the reaction;

[0048] (3) Vacuum dehydration for 2.0 hours until the viscosity is 3.0 Pa·s, cooling and discharging to obtain a phenolic resin binder with evenly dispersed nano-graphite.

[0049] 2. Preparation of low carbon magnesia carbon bricks

[0050] (1) Weigh separately: 100 parts by...

Embodiment 3

[0056] Example 3: Preparation of phenolic resin containing nano-carbon powder and nano-carbon modified low-carbon magnesia-carbon brick

[0057] 1. Preparation of phenolic resin

[0058] (1) 100 parts by weight of phenol, 120 parts by weight of 37% aqueous formaldehyde solution and 1.2 parts by weight of triethanolamine are added to the reactor together, while stirring, slowly add 22 parts by weight of nano-graphite with an average particle diameter of 50 nm, and ultrasonically disperse for 60 minutes , and then the temperature was kept at 50°C and stirred for 30 minutes;

[0059] (2) Add 3.0 parts by weight of NaOH, adjust the pH value to 9.0, control the temperature to 100° C. and keep it warm for 2.0 hours to stop the reaction;

[0060] (3) Vacuum dehydration under reduced pressure for 6.0 hours until the viscosity is 2.0 Pa·s, then cooling and discharging to obtain the nano-graphite phenolic resin binder.

[0061] 2. Preparation of low carbon magnesia carbon bricks

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com