Method for determining allowable defect of honeycomb sandwich layer of helicopter

A technology of honeycomb interlayer and determination method, which is applied in special data processing applications, instruments, electrical digital data processing, etc. It can solve problems such as difficult determination, difficult repair, and difficulty in ensuring partial detachment/leakage of honeycomb and aluminum alloy panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

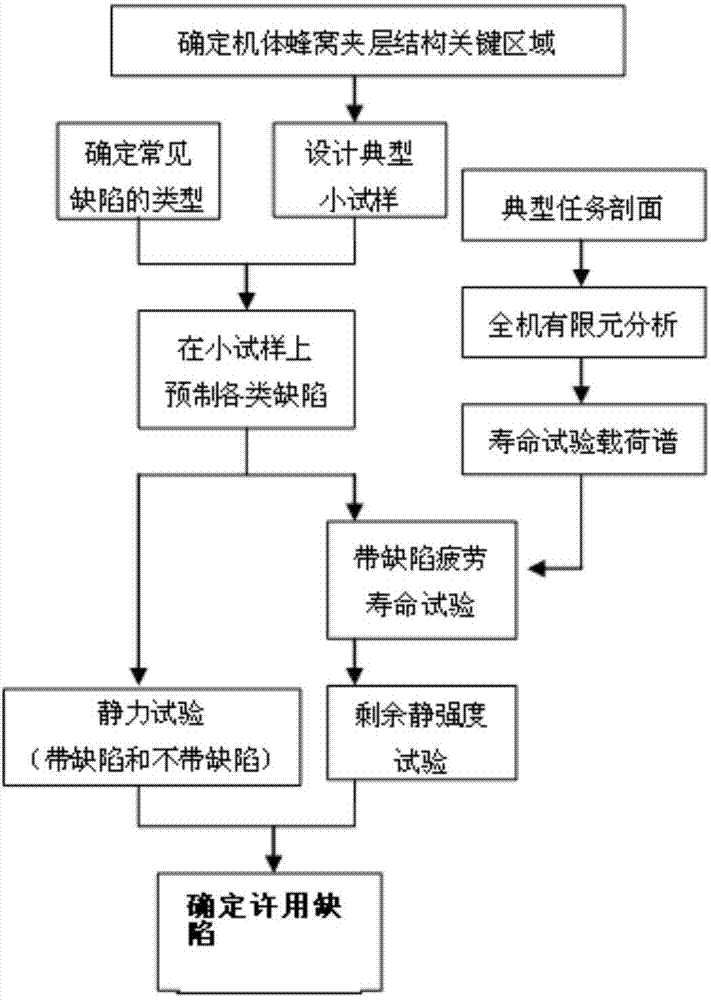

[0022] In order to solve the above problems, the present invention proposes a method for determining the allowable defects of the helicopter honeycomb sandwich. The allowable value or disposal measures for such manufacturing deviations can reduce the manufacturing cost of the helicopter and reduce the risk of using the helicopter honeycomb sandwich structure with defects.

[0023] The method for determining allowable defects of the helicopter honeycomb interlayer of the present invention comprises the following steps:

[0024] The first step is to determine the types of common defects according to the manufacturing, use and maintenance conditions;

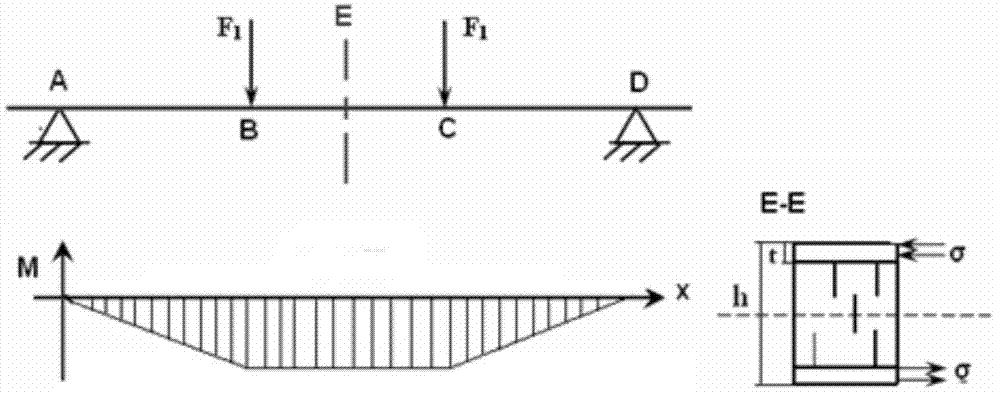

[0025] The second step is to determine the stress of the key area of the honeycomb sandwich structure on the aircraft through the analysis of the finite element model of the whole aircraft and the flight load;

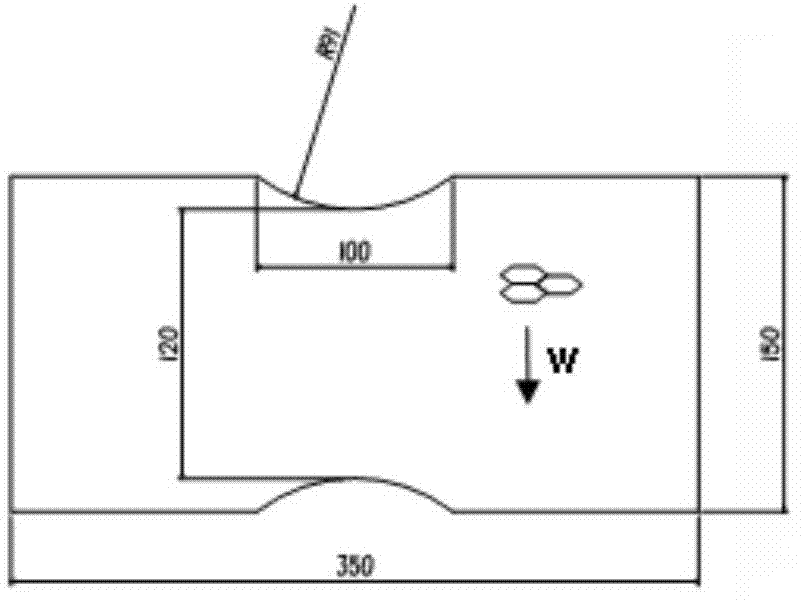

[0026] At the same time, design a small sample of a honeycomb sandwich structure with a typical configuration, and pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com