Residual intensity evaluation method of corrosion defect contained steam injection pipeline compensator bent pipe

A steam injection pipeline and compensator technology, applied in the direction of applying stable tension/pressure to test material strength, instruments, measuring devices, etc., can solve problems such as unsuitable elbows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Measure the specifications of the compensator elbow and the geometric dimensions of corrosion defects, measure the tensile strength and yield strength of the pipe, and calculate the flow stress of the pipe. The results are shown in Table 1:

[0070] Table 1 Related parameters of test tube sample

[0071] Defect depth

(mm)

Defect length

(mm)

Wall thickness

(mm)

Average pipe diameter

(mm)

Mean radius

(mm)

(MPa)

3.01

70.40

0.001

10.86

103.14

51.57

410

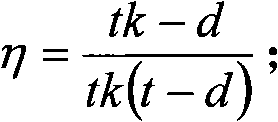

[0072] It should be noted that when calculating the burst pressure, the allowable stress of the material is not used, but the flow stress of the pipe is used. This is because the allowable stress is not an inherent property of the material. The allowable stress is a response to the ultimate strength of the material in different shapes and different working environments. Plastic deformation occurred during the blasting of the pipe section, so the flow stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com