Strain control method for measuring residual strength and residual service life of composite material

A strain control, composite material technology, applied in analysis materials, measurement devices, special data processing applications, etc., can solve problems such as difficult model determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

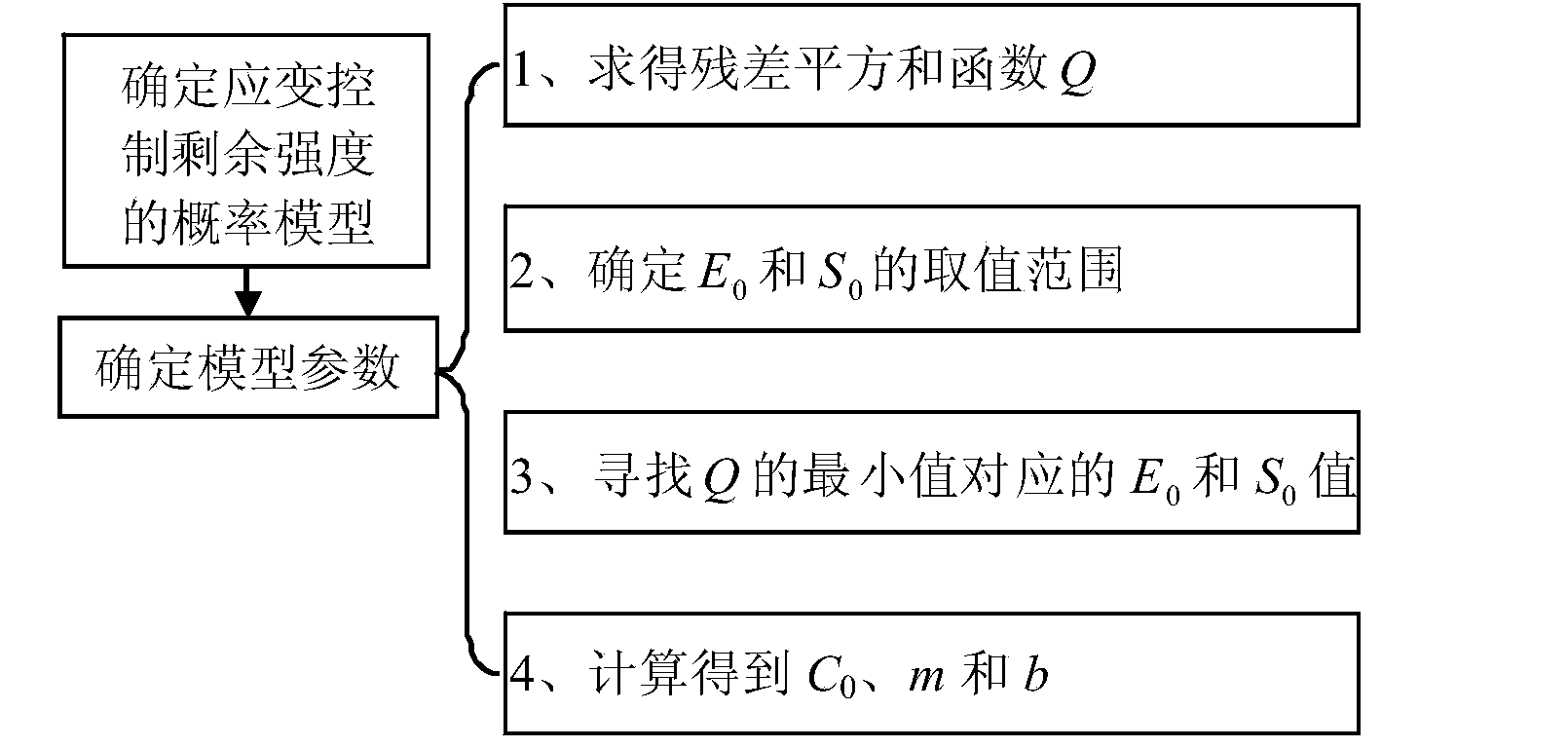

[0066] figure 1 It is the block flow chart of method for the present invention, and the present invention is divided into three major steps and realizes, specifically:

[0067] Step 1. Strain-controlled residual strength model

[0068] Fatigue damage leads to a decrease in strength, and the effective modulus drop of the composite material over time can be expressed as

[0069] dR ( n ) dn = - f ( r , s , ω ) R b - 1 ( n ) - - - ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com