Inorganic binder for 3D printing and preparation method thereof

An inorganic binder and 3D printing technology, applied in the field of foundry, can solve the problems of low core strength, separation of molding sand, increase the amount of water glass added, etc., to achieve excellent performance, meet the requirements of foundry use, and low residual strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

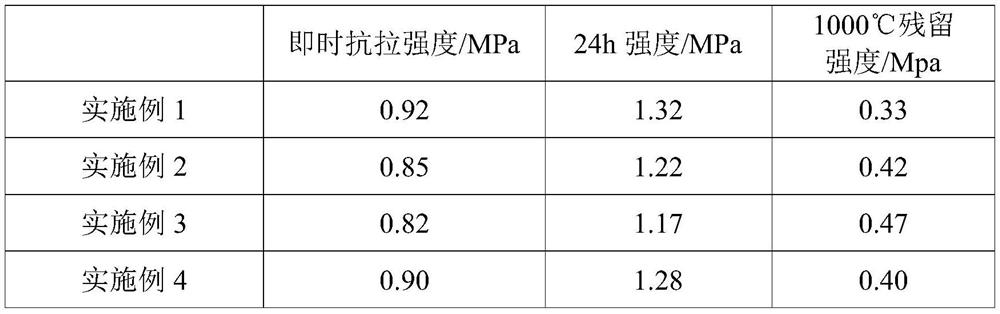

Examples

Embodiment 1

[0026] An inorganic binder for 3D printing, including two components of an inorganic binder and a powder accelerator used in conjunction, wherein the mass-number ratio of the inorganic binder to the powder accelerator is inorganic binder: powder Accelerator=100:40; the inorganic binder includes the following raw materials in parts by mass: 40 parts of sodium silicate solution, 40 parts of potassium silicate solution, 0.5 part of gamma alumina, 15 parts of potassium hydroxide, sodium hydroxide 0.5 parts, 10 parts of water-soluble epoxy resin, 0.5 parts of modified starch, 0.1 part of water reducer, 3 parts of surfactant; the powder accelerator includes the following raw materials in parts by mass: 40 parts of silica fume, superfine calcium oxide 20 parts, 20 parts of superfine titanium oxide, 2 parts of superfine zirconia, 5 parts of superfine zinc oxide, 10 parts of superfine yttrium oxide, and 0.5 part of graphite.

[0027] Add sodium silicate, potassium silicate and sodium h...

Embodiment 2

[0029] An inorganic binder for 3D printing, including two components of an inorganic binder and a powder accelerator used in conjunction, wherein the mass-number ratio of the inorganic binder to the powder accelerator is inorganic binder: powder Material accelerator=100:20; The inorganic binder includes 50 parts of raw material sodium silicate solution, 30 parts of potassium silicate solution, 10 parts of gamma alumina, 0.5 part of potassium hydroxide, sodium hydroxide 15 parts, 10 parts of water-soluble epoxy resin, 10 parts of modified starch, 3 parts of water reducer, 0.1 part of surfactant; the powder accelerator includes the following raw materials in parts by mass: 50 parts of silica fume, superfine calcium oxide 15 parts, 10 parts of superfine titanium oxide, 0.5 parts of superfine zirconia, 1 part of superfine zinc oxide, 2.4 parts of superfine yttrium oxide, and 2 parts of graphite.

[0030] First add sodium silicate, potassium silicate and sodium hydroxide into the r...

Embodiment 3

[0032] An inorganic binder for 3D printing, including two components of an inorganic binder and a powder accelerator used in conjunction, wherein the mass-number ratio of the inorganic binder to the powder accelerator is inorganic binder: powder Material accelerator=100:60; the inorganic binder includes the following raw materials in parts by mass: 60 parts of sodium silicate solution, 20 parts of potassium silicate solution, 5 parts of gamma alumina, 10 parts of potassium hydroxide, 5 parts of sodium, 5 parts of water-soluble epoxy resin, 8 parts of modified starch, 2.5 parts of water reducer, 2.5 parts of surfactant; the powder accelerator includes the following raw materials in parts by mass: 60 parts of silica fume, superfine oxidation 10 parts of calcium, 15 parts of superfine titanium oxide, 10 parts of superfine zirconia, 10 parts of superfine zinc oxide, 1 part of superfine yttrium oxide, and 1 part of graphite.

[0033] Add sodium silicate, potassium silicate and sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com