Method for changing strength of shell by impregnating with organic binder

An organic binder and strength technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of reducing slurry stability, type, content, length, affecting slurry and shell performance, etc., to increase The effect of room temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

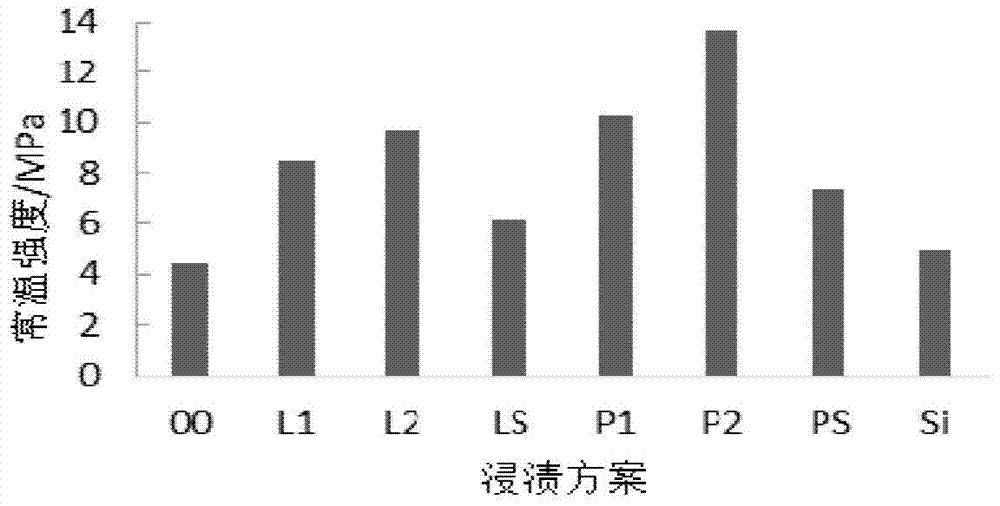

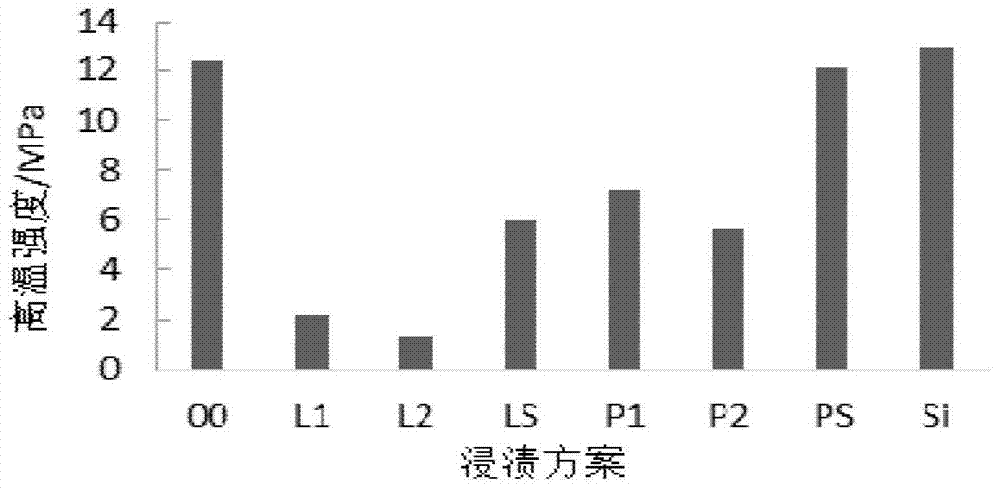

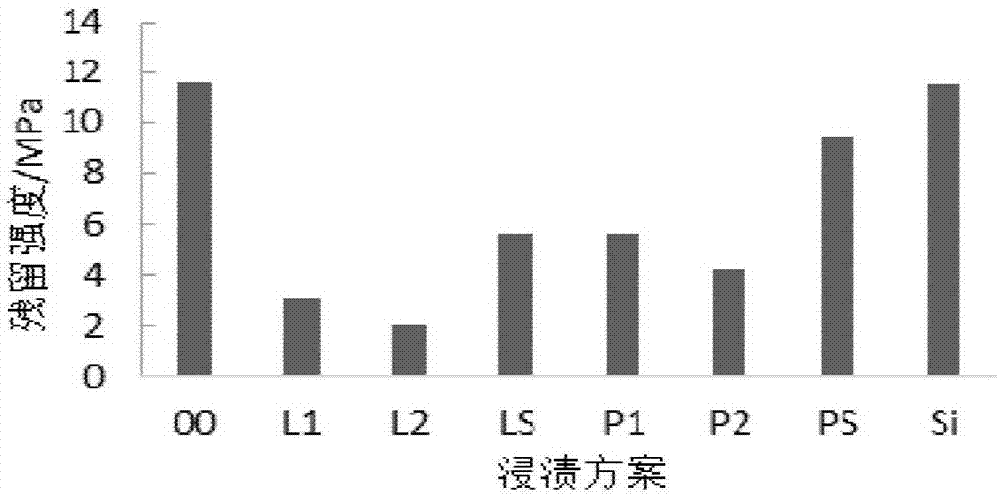

[0015] The present invention aims to provide a method for changing the strength of the investment casting mold shell by impregnating an organic binder, so as to solve the problems of insufficient normal temperature strength and high residual strength of the current mold shell. Taking different impregnation schemes of silica sol-kaolin shells as examples, the present invention will be further described in detail in combination with specific examples and accompanying drawings.

[0016] As shown in Table 1, it shows the preparation and impregnation process of the shell, the binder is silica sol GS30, the refractory material is calcined kaolin, the drying time between layers and after impregnation is 24 hours, and the impregnation time is 5 minutes.

[0017] Table 1 Shell preparation process

[0018]

[0019] Impregnation solution: 00-none; L1-low latex; L2-high glue; P1-low PVA; P2-high PVA; Si-silica sol

[0020] The results of normal temperature strength, high temperature s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com