CO2 hardened silicate-bonded sand additive agent and formative technology thereof

A water glass sand and additive technology, which is applied in the manufacture of tools, casting molding equipment, metal processing equipment, etc., can solve the problems of poor collapsibility of old sand, large amount of water glass added, and reduced core strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

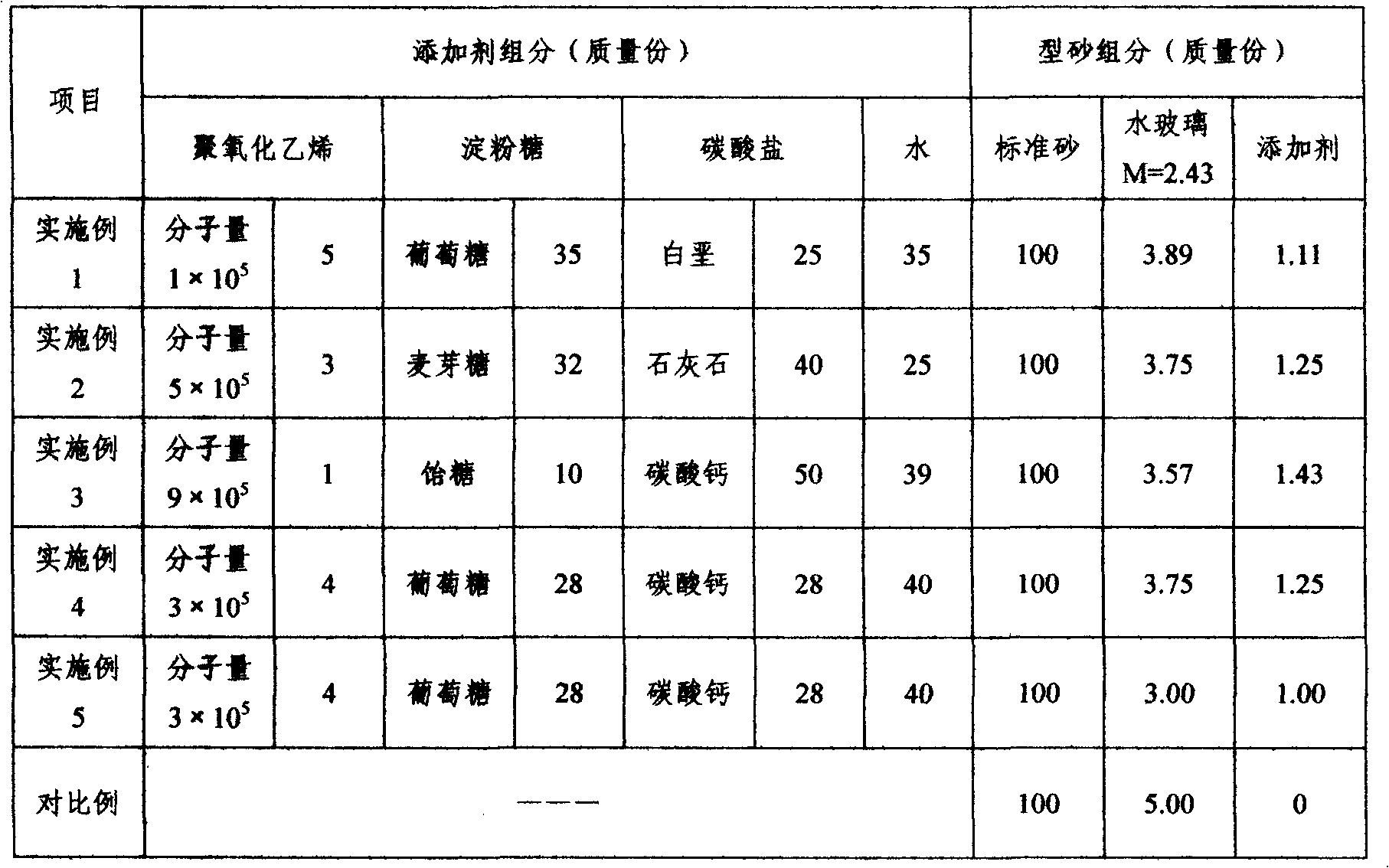

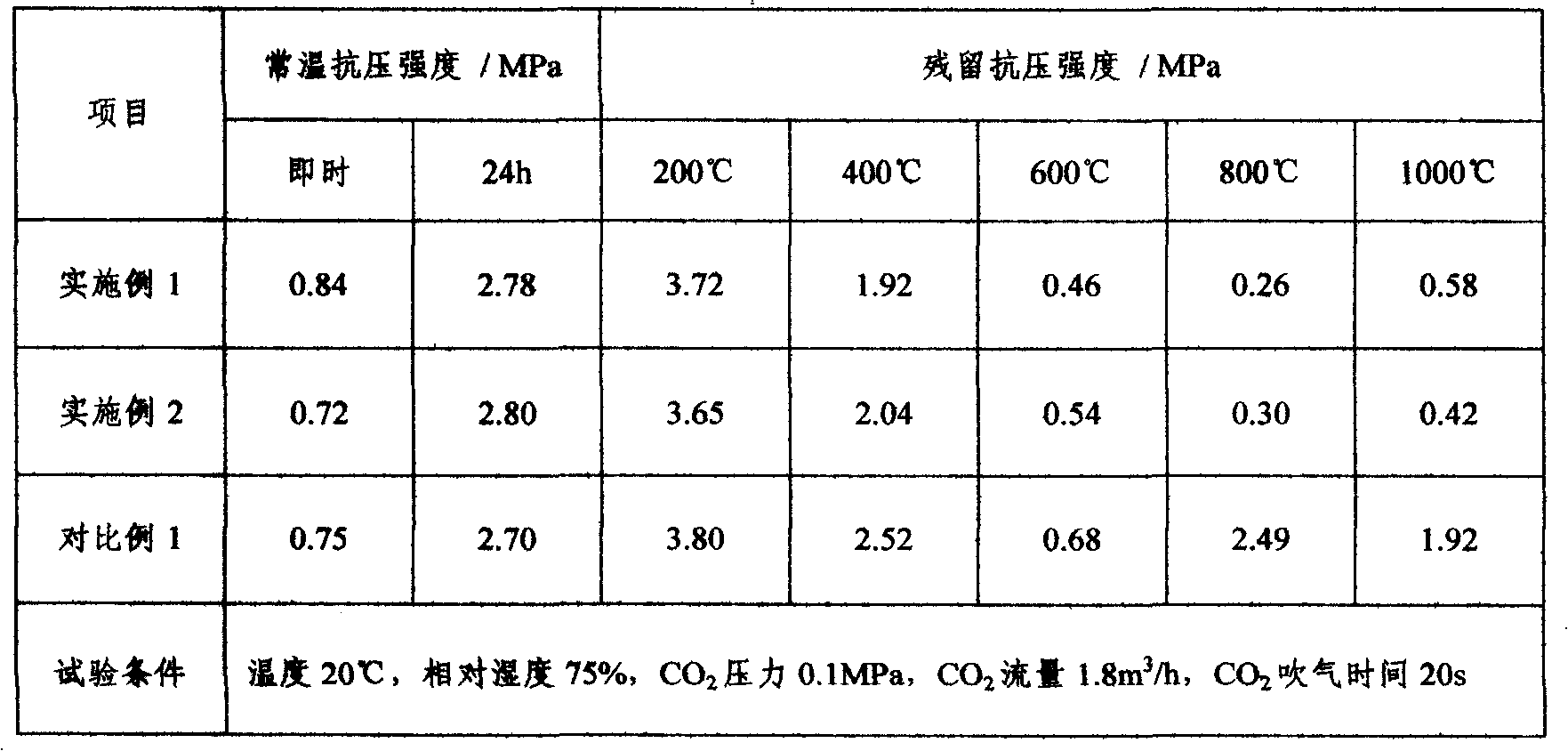

Embodiment 1

[0015] According to the content of additive components specified in Table 1, the molecular weight is 1×10 5 The polyethylene oxide resin and self-chalk are added to glucose and water, and stirred evenly with a high-speed disperser to obtain a water glass sand additive. Then mix the molding sand for the test in the SHY type sand mixer according to the molding sand components specified in Table 1. The additive and water glass (mass ratio 1:3.5) are mixed first and then added. The sand mixing time is 2 minutes, and the sand is produced to Φ50mm× 50mm cylindrical standard sample, blow CO under the test conditions shown in Table 2 2 After hardening, measure the instant strength at room temperature and 24h storage strength of the sample with a SWY strength testing machine. In addition, after the prepared samples were left for 24 hours, they were kept in box-type resistance furnaces at different temperatures for 20 minutes, taken out and cooled to room temperature, and then the high...

Embodiment 2

[0017] According to the content of additive components specified in Table 1, the molecular weight of polyethylene oxide resin is 5×10 5 , And replace chalk with limestone, maltose replace glucose, repeat the method for embodiment 1 and make water glass sand additive. Then press the specified molding sand components in Table 1, replace the mass ratio of additives and water glass with 1: 3, repeat the method of Example 1 for sand mixing, sample preparation, and test various strength values. The test results are shown in Table 2.

Embodiment 3

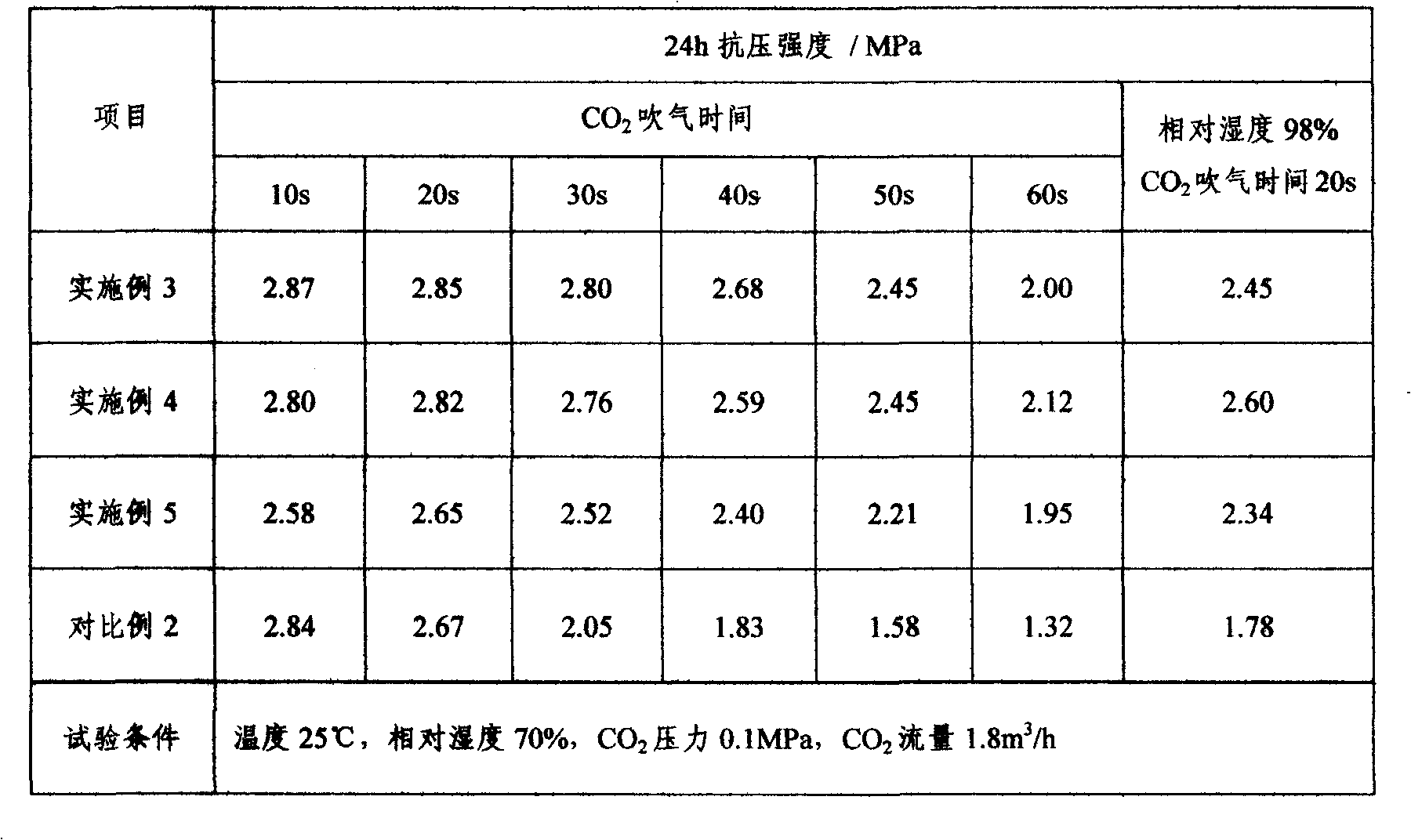

[0021] According to the content of additive components specified in Table 1, the molecular weight is 8×10 5 Add polyoxyethylene resin and calcium carbonate into maltose and water, and stir evenly with a high-speed disperser to obtain a water glass sand additive. Then mix the molding sand for the test in the SHY type sand mixer according to the molding sand components specified in Table 1. The additive and water glass (mass ratio 1:2.5) are mixed first and then added. The sand mixing time is 2 minutes, and the sand is produced to Φ50mm× 50mm cylindrical standard sample, under the test conditions shown in Table 3, blow the sample with CO at different times 2 After hardening, measure its 24h storage strength with SWY strength testing machine. In addition, the sample with a blowing time of 20s is placed in an environment with high relative humidity, and its 24h storage strength is measured. The test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com