Method for manufacturing split type fiber knitted wiping cloth

A manufacturing method and wiping cloth technology, which are applied in knitting, fiber processing, weft knitting and other directions, can solve the problems of uneven fiber opening and poor shrinkage of the wiping cloth, and achieve the effect of saving production costs and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

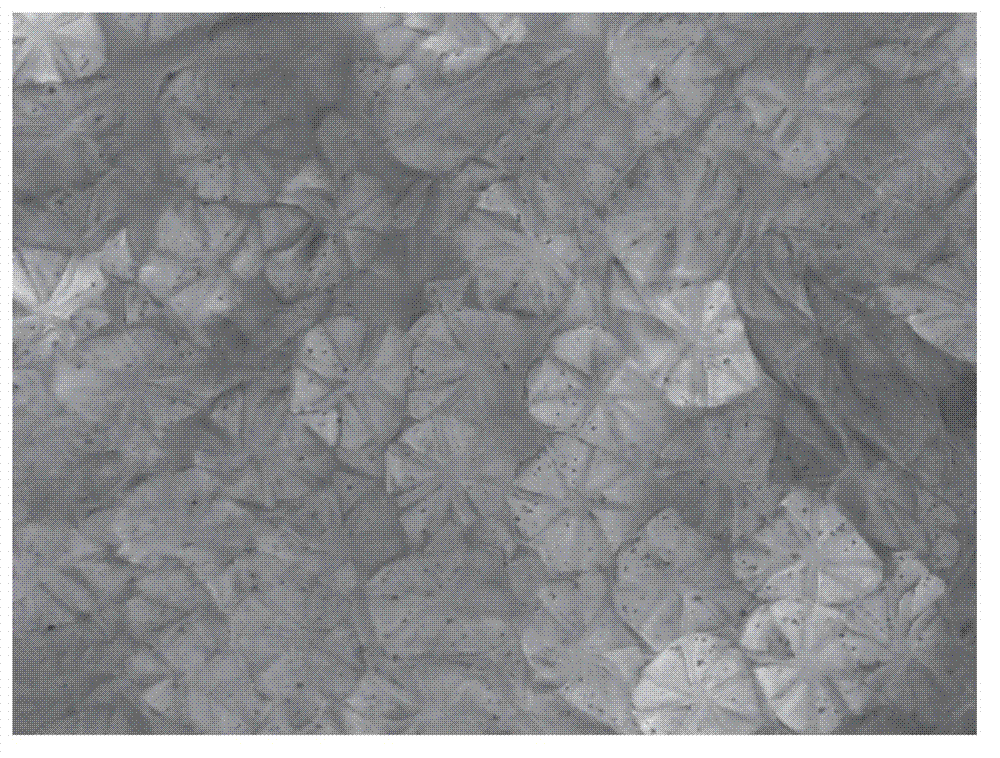

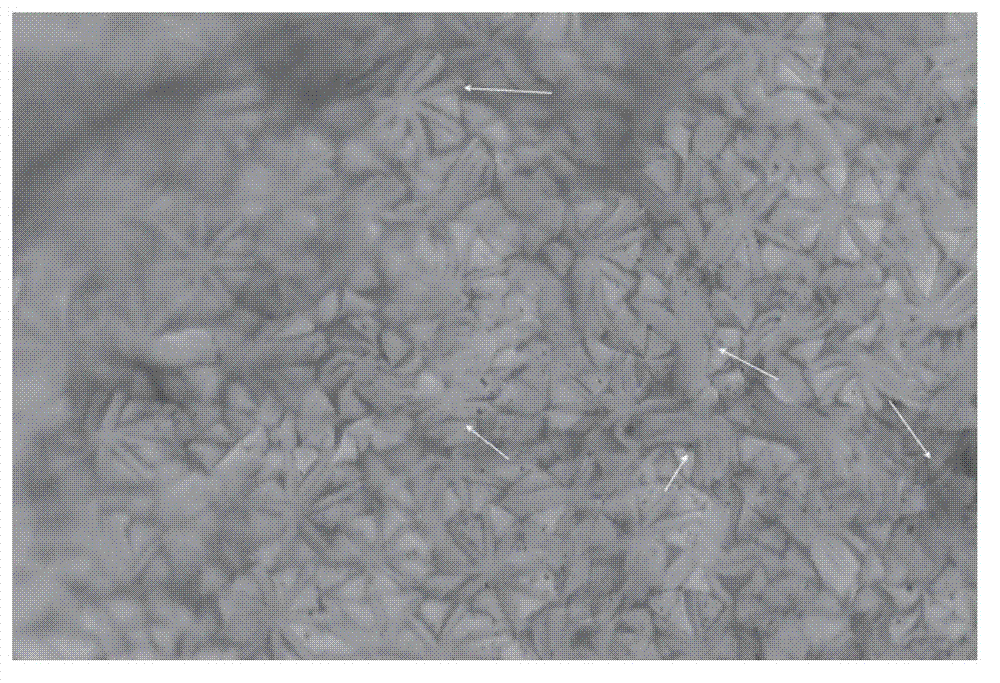

Image

Examples

Embodiment 1

[0062] This embodiment is an embodiment of producing 80D / 36F DTY cotton wool.

[0063] Yarn count: 80D / 36F DTY polyester superfine fiber, produced by Wuxi Jinda Superfine Fabric Co., Ltd.;

[0064] Loom: 40G / 30″I3P284 Delo Cotton Wool Machine, produced by Germany Delo Textile Machinery Factory.

[0065] A method for manufacturing a segmented fiber knitted wiping cloth, which uses orange-petal-shaped polyester-nylon composite filaments as raw materials, and includes the following steps:

[0066] a) Weaving process; raw material: 80D / 36F DTY polyester superfine fiber. Loom: 40G / 30″I3P284 Delo cotton and wool machine, thread length 10.0cm / 50 coils, speed 14r / min, in addition to strictly control skipped stitches, hooked yarns, cross paths, straight strips, foreign fiber mixing, etc., using 8 petals Split yarn.

[0067] b) Degreasing treatment process; carried out on the overflow dyeing machine, the specific process is: put the gray cloth into water at 60 ° C for 20 minutes to w...

Embodiment 2

[0073] This embodiment is an embodiment of producing 75D / 24F DTY cotton wool.

[0074] Yarn count: 75D / 24F DTY polyester superfine fiber, produced by Wuxi Jinda Superfine Fabric Co., Ltd.;

[0075] Loom: 40G / 30″I3P284 Delo Cotton Wool Machine, produced by Germany Delo Textile Machinery Factory.

[0076] A method for manufacturing a segmented fiber knitted wiping cloth, which uses orange-petal-shaped polyester-nylon composite filaments as raw materials, and includes the following steps:

[0077] a) Weaving process; raw material: 75D / 24FDTY polyester superfine fiber. Loom: 40G / 30″I3P284 Delo cotton and wool machine, thread length 10.0cm / 50 coils, speed 14r / min, in addition to strictly control skipped stitches, hooked yarns, cross paths, straight strips, foreign fiber mixing, etc., using 8 petals Split yarn.

[0078] b) Degreasing treatment process: carried out on the overflow dyeing machine, the specific process is: put the gray cloth into 60°C water for 20 minutes and then a...

Embodiment 3

[0084] This embodiment is an embodiment of producing 60D / 24F DTY cotton wool.

[0085] Yarn count: 60D / 24FDTY polyester superfine fiber, produced by Wuxi Jinda Superfine Fabric Co., Ltd.;

[0086] Loom: 50G / 30″I3P284 Delo Cotton Wool Machine, produced by Germany Delo Textile Machinery Factory.

[0087] a) Weaving process; raw material: 60D / 24F DTY polyester superfine fiber. Loom: 50G / 30″I3P284 Delo cotton and wool machine, thread length 8.4cm / 50 coils, speed 12.6r / min, in addition to strictly control skipped stitches, hooked yarns, cross paths, straight strips, foreign fiber mixing, etc., using 8 petals Type open fiber yarn.

[0088] b) Degreasing treatment process; carried out on the overflow dyeing machine, the specific process is: put the gray cloth into water at 60 ° C for 20 minutes to wet, add degreasing yarn agent TF-115B 3g / L, smoothing agent BT- 443g / L and 98wt% NaOH 1g / L, and then treated at 95°C for 30min (the treatment refers to soaking the gray cloth in water),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com