Light-colored microporous EPDM sponge rubber and preparation method thereof

The technology of EPDM rubber and EPDM is applied in the field of light-colored microporous structure EPDM sponge rubber and its preparation field, which can solve the problem that rubber sealing strips do not have hygroscopic properties, and can achieve hygroscopic properties, Good hygroscopic performance, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

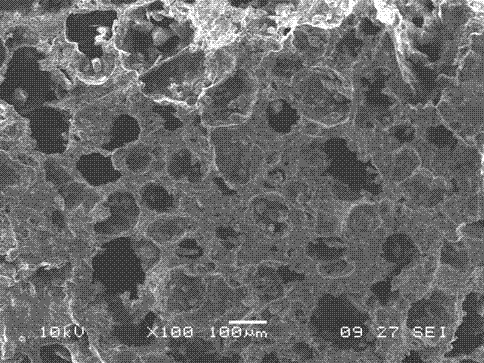

Embodiment 1

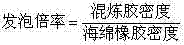

[0031] The EPDM sponge rubber described in this embodiment is composed of an EPDM rubber matrix, a foaming agent, a colorant, a filling reinforcing agent, a plasticizer, and related vulcanizing agents and vulcanization assistants. The feature of this embodiment is that the colorant rutile titanium dioxide, ultramarine blue and fluorescent whitening agent are introduced into the rubber compounding system as a kind of auxiliary agent, so that the rubber material has a white or close to white color, which expands the application of rubber products scope. The characteristics of this embodiment also include a kind of light-colored EPDM with uniform cells and low compression set, which is made by combining the thermal decomposition of the foaming agent and the promotion of the accelerator in the EPDM rubber. Sponge rubber material.

[0032] The composition of this embodiment includes 100 parts by mass of EPDM rubber, 6 parts of blowing agent OBSH, 3 parts of stearic acid, 5 parts o...

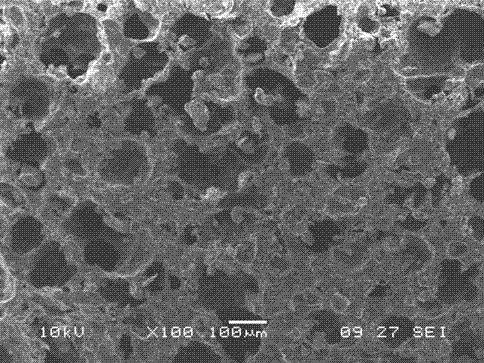

Embodiment 2

[0041] The composition of this example is consistent with that of Example 1. The difference between the composition of this example and Example 1 is that 1 part of PZ, 1.5 parts of BZ, 2 parts of Si-69, 1.5 parts of KH550, 30 parts of paraffin oil, 30 parts of naphthenic oil are used, and 110 parts of active calcium is used instead of super Fine talcum powder is used as a filler, and 1 part of antiaging agent 246 is used instead of antiaging agent 2246.

[0042] The preparation method and performance test standard of this example are the same as those of Example 1, and the performance test results of the light-colored EPDM sponge rubber obtained in this example are shown in Table 1.

Embodiment 3

[0044] The composition of this example is consistent with that of Example 1. The difference between the composition of this example and Example 1 is that 1 part of PZ, 1.5 parts of BZ, 1.5 parts of DPTT, 1.5 parts of EZ, 1 part of Si-69, 1 part of KH550, 0.2 part of ultramarine blue are used, and 110 parts of 3A molecular sieve powder are used Alternative to extra fine talc.

[0045] The preparation method and performance testing standard of this embodiment are the same as those of Example 1. The performance test results of the light-colored EPDM sponge rubber obtained in this embodiment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com