Modified inorganic binder sand with collapsibility and preparation method

An inorganic binder and collapsible technology, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of heavy welding and cleaning work, large amount of binder, and peeling of castings. Achieve the effect of reducing labor intensity, reducing residual strength and improving collapsibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

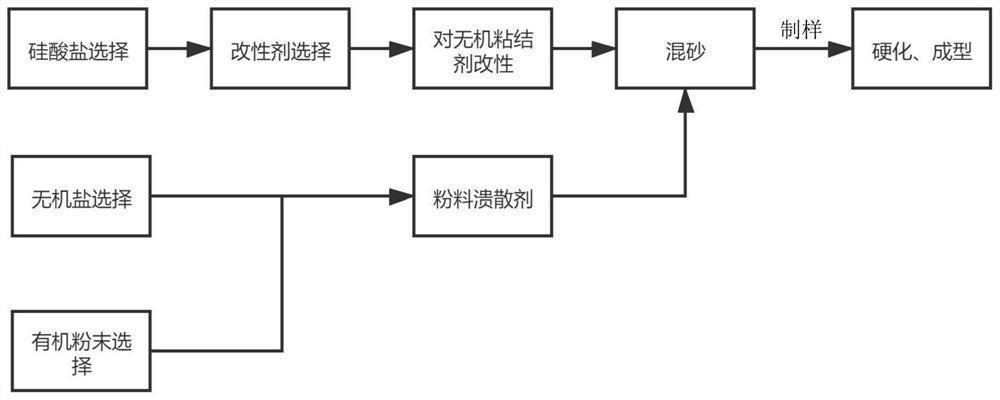

Method used

Image

Examples

preparation example Construction

[0051] The first stage is in the preparation process of the inorganic binder, in the above steps S210, S220 and S230, through the modification of the inorganic binder, the bond strength of the inorganic binder sand is improved, and the binding strength of the inorganic binder is reduced. The addition amount can significantly improve the collapsibility of the inorganic binder sand. At the same time, in step S220, after the modifiers such as phosphate and borate in the modifier are modified and fused with the inorganic binder, the modifier Evenly dispersed in the inorganic binder, in the curing process, together with the inorganic binder to form a bonding network structure, which can limit the growth of the gel colloidal particles and make them small. Bonding effect, and can improve the bond strength of inorganic binders. Under the action of high temperature during pouring, the melting and cooling methods of the modifier and the inorganic binder are different, which can play a r...

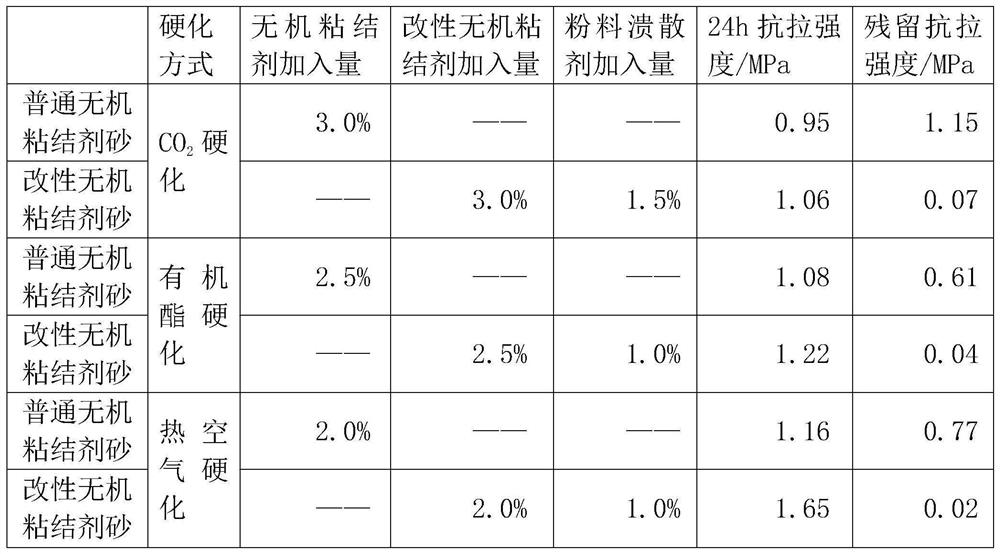

Embodiment 1

[0056] Embodiment 1: Preparation of modified inorganic binder sand, take 100 parts of silica sand, add 3.0% by weight of silica sand to the modified inorganic binder, mix for 2 minutes, add 1.5% by weight of silica sand powder disintegrating agent, Mixed for 2 minutes, then hardened by CO2, 24 hours test tensile strength was 1.06MPa, residual tensile strength was 0.07MPa.

Embodiment 2

[0058] Embodiment 2: Preparation of modified inorganic binder sand, take 100 parts of silica sand, add 2.5% of silica sand weight percent modified inorganic binder, mix for 2 minutes, add 1.0% of silica sand weight percent powder disintegrating agent, Mixed for 2 minutes, and then hardened by organic ester, the 24-hour test tensile strength was 1.22MPa, and the residual tensile strength was 0.04MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com